Manufacturing method of a piezoelectric micro-cantilever beam probe

A technology of a micro-cantilever beam and a manufacturing method, which is applied to piezoelectric devices/electrostrictive devices and other directions, can solve the problems of influence, small probe sharpness, and poor needle tip quality, and achieves cost reduction, low process equipment requirements, and maintenance sharpness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

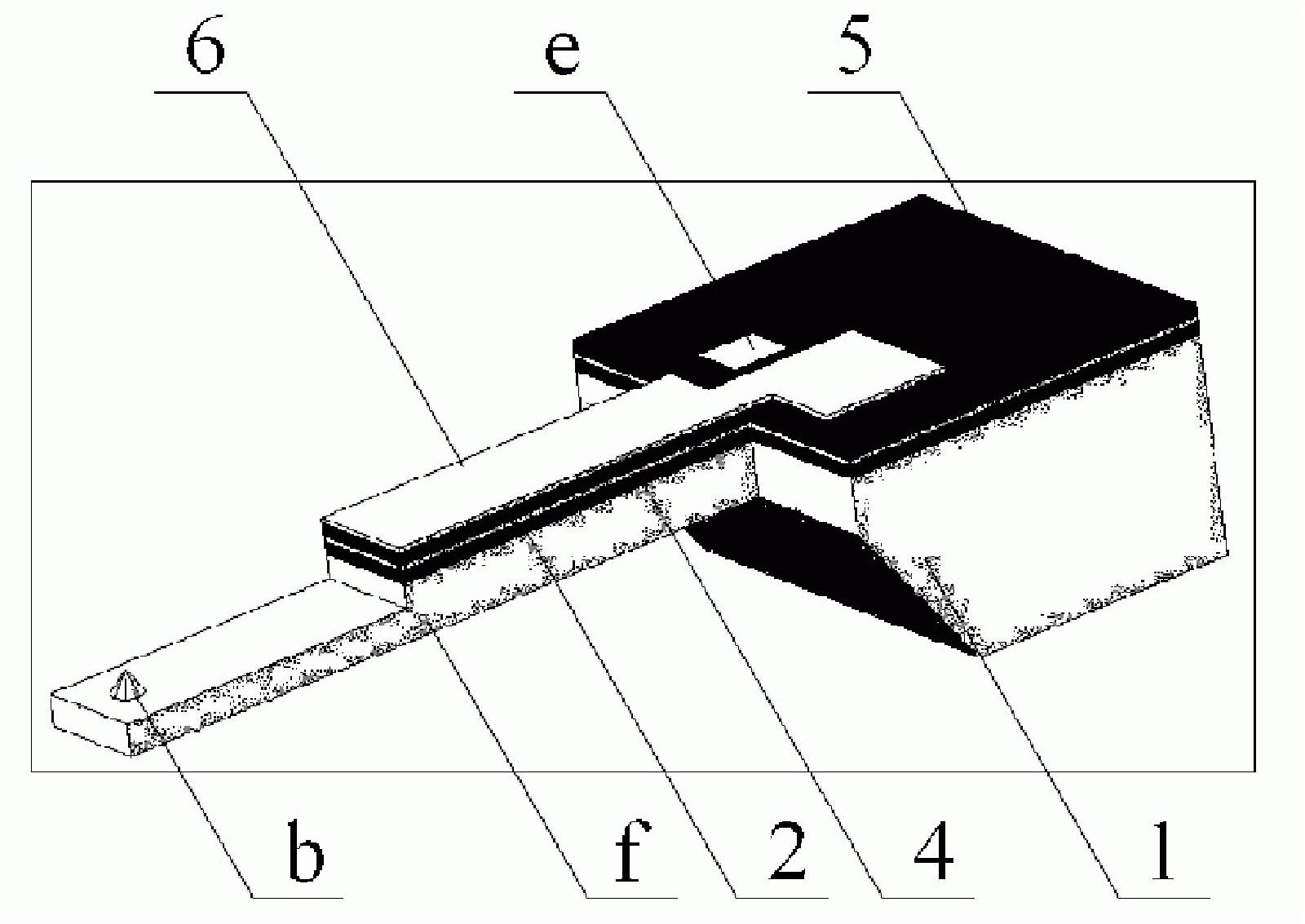

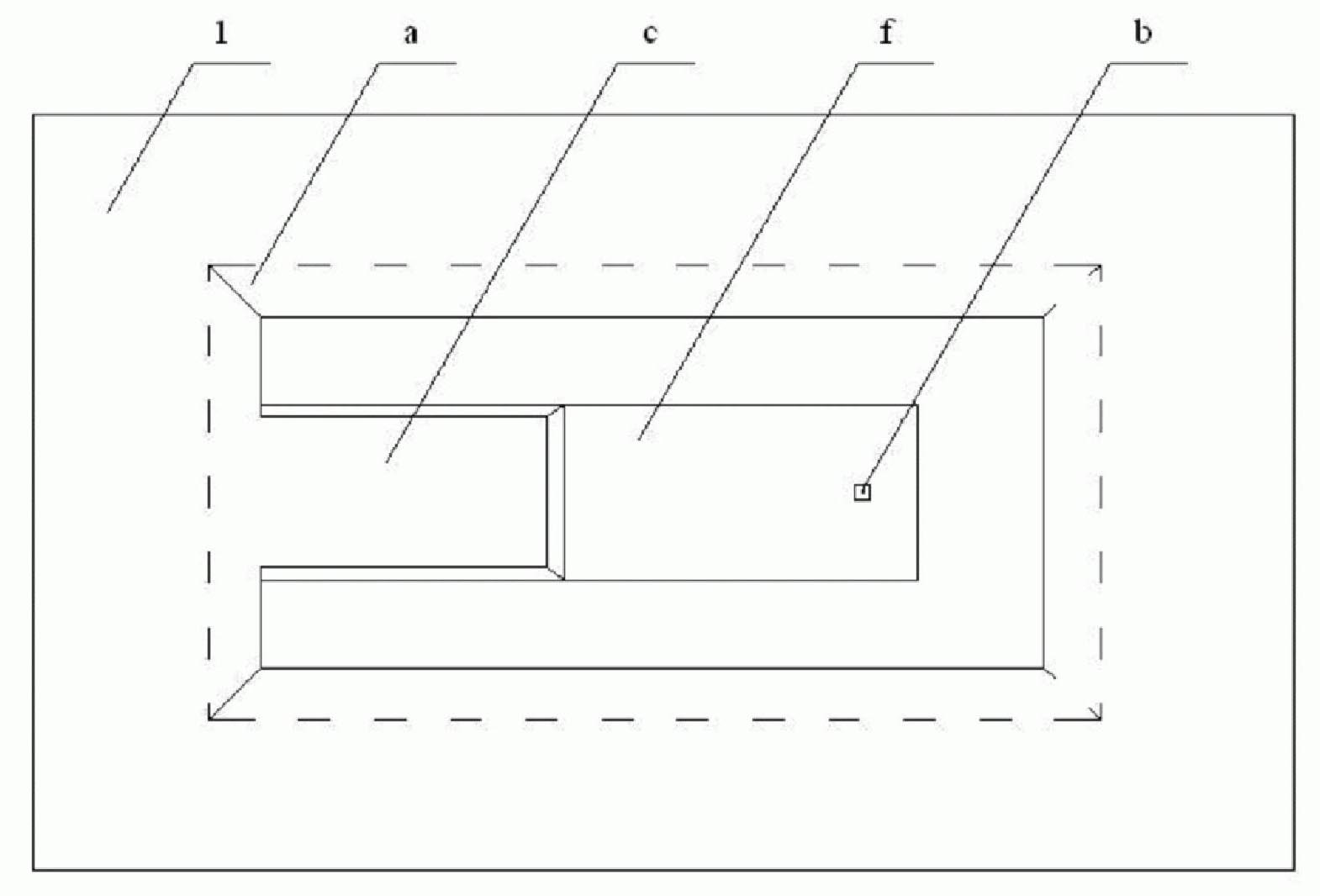

[0043] For the piezoelectric micro-cantilever probe in this embodiment, the length and width of the micro-cantilever are 450 microns and 70 microns, and the tip height is 5 microns. A micro-cantilever beam probe was fabricated using n-type (100) double-sided polished single-crystal silicon wafers with a thickness of 220 microns. Its specific production process is as follows:

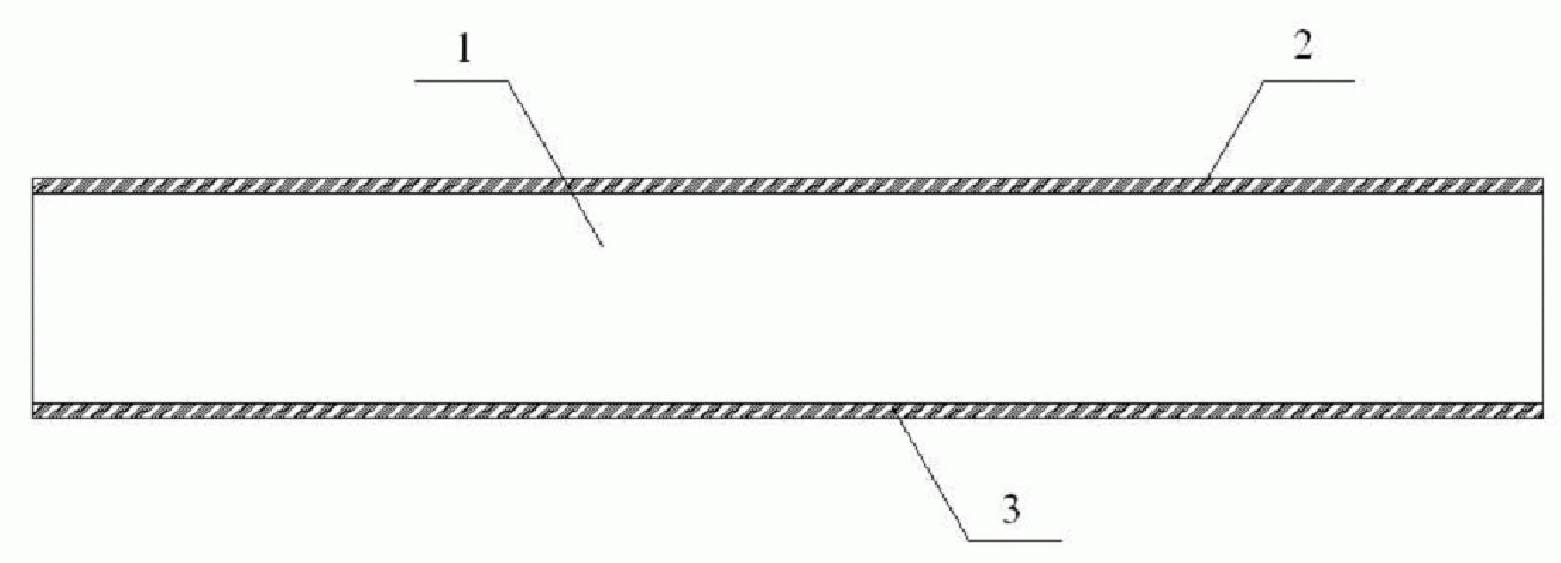

[0044] Conventional thermal oxidation monocrystalline silicon wafer 1 forms upper surface silicon dioxide layer 2 and lower surface silicon dioxide layer 3 on single crystal silicon wafer, and the thickness of oxide layer is about 1.3 microns (attached Figure 3.1 ).

[0045] Silicon wafer back treatment process: Rectangular windows are photolithographically etched on the back, and silicon dioxide is etched with hydrofluoric acid buffer solution (BHF), and a rectangular window pattern 3' with silicon dioxide removed is produced (attached Figure 3.2 );

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com