Quenching and tempering heat treatment device

A heat treatment device, quenching and tempering technology, applied in the direction of quenching device, heat treatment furnace, heat treatment equipment, etc., can solve the problems of long time, unstable product hardness, wide control range, etc., achieve enhanced hardness stability and improve energy utilization The effect of increasing the rate and improving the accuracy of the straight line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

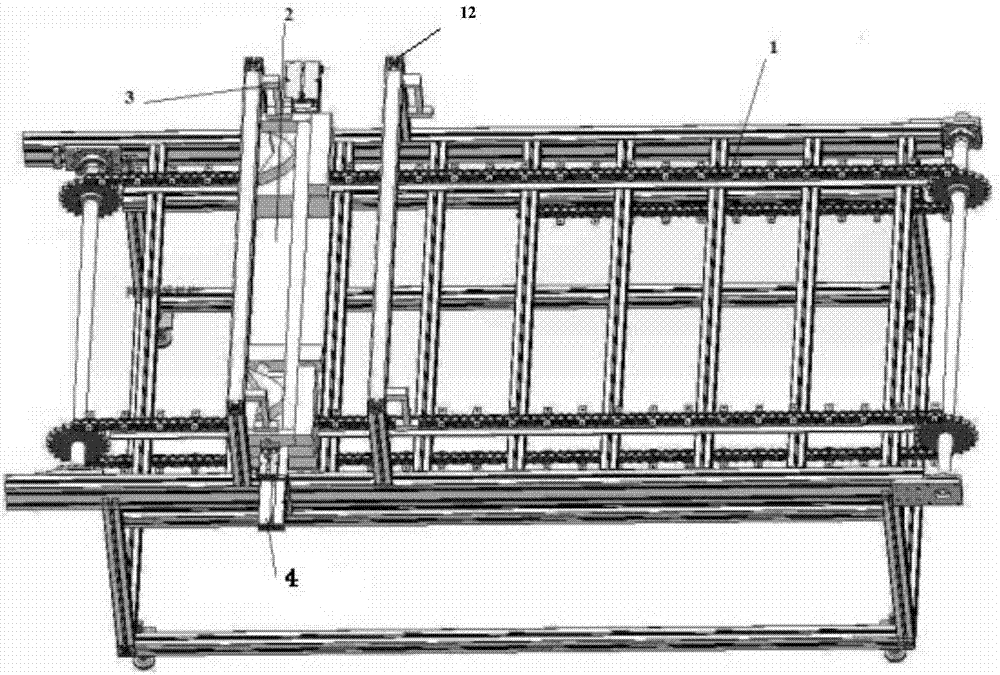

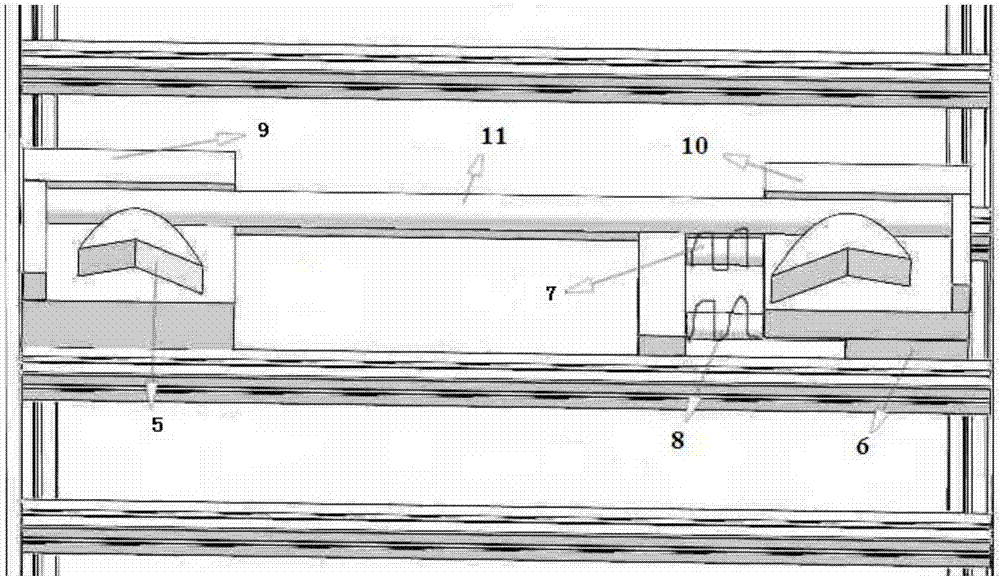

[0022] A quenching and tempering heat treatment device, including an integral transmission mechanism, a clamping and straightening mechanism, an electrode automatic connection mechanism, a heating mechanism, a cylinder pressing mechanism and a sensor, the clamping and straightening mechanism includes a pressing cam, a fixed end, a movable end, Springs, guide columns and sliders, and pressing cams are set on the support table at both ends of the clamping and straightening mechanism to clamp steel materials. One end of the clamping and straightening mechanism is the fixed end, and the other end is the movable end. The support at the movable end Two sliders are installed below the table, and the movable end moves back and forth on the guide post through the sliders to make the spring compressed and stretched. The electrode automatic connection mechanism is a telescopic connecting rod, and an electrode head is arranged under the telescopic connecting rod, and the electrode head is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com