Gun drill for deep hole machining based on piezoelectric ceramic materials for deviation rectification and deviation rectification method

A piezoelectric ceramic and piezoelectric technology, which is used in boring/drilling, metal processing equipment, drilling/drilling equipment, etc. Overcome the effect of circumferential asymmetry and good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

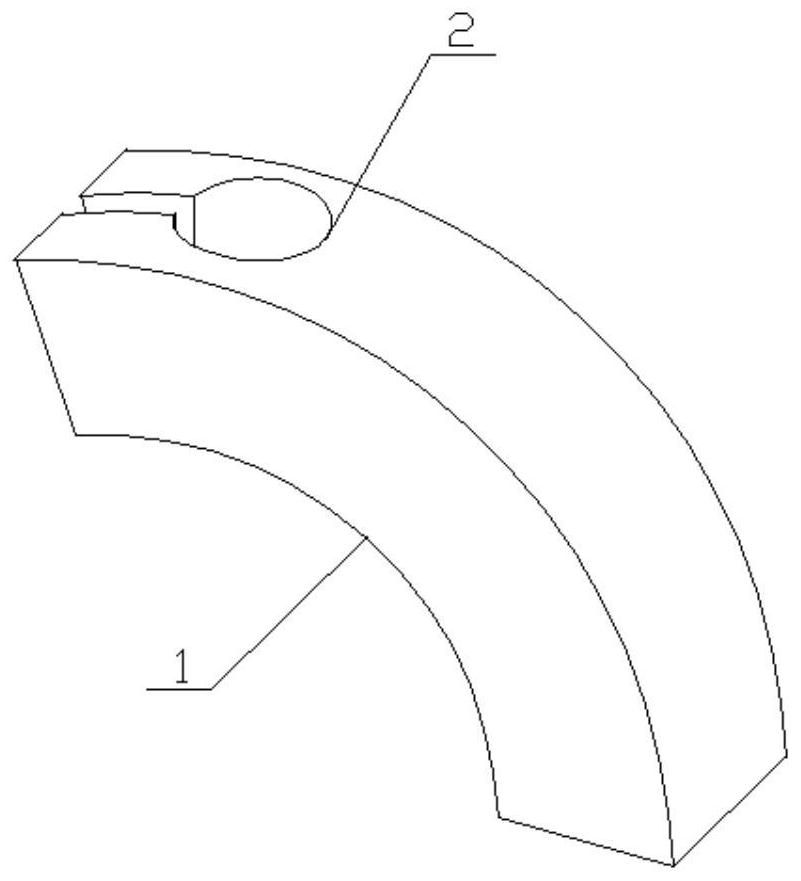

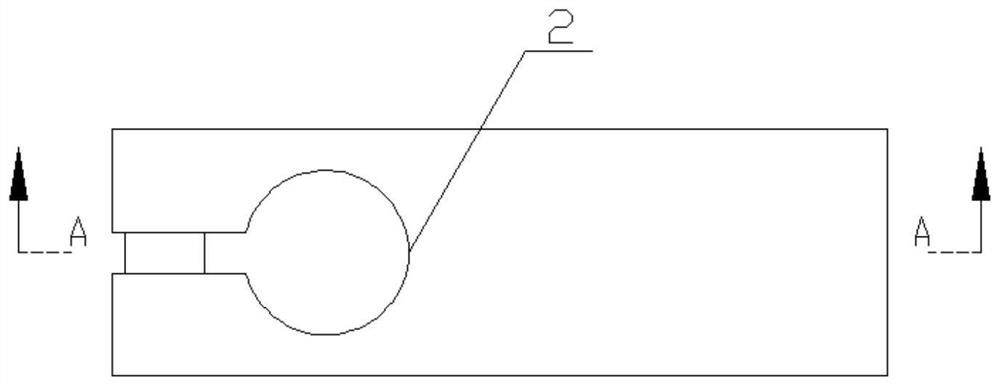

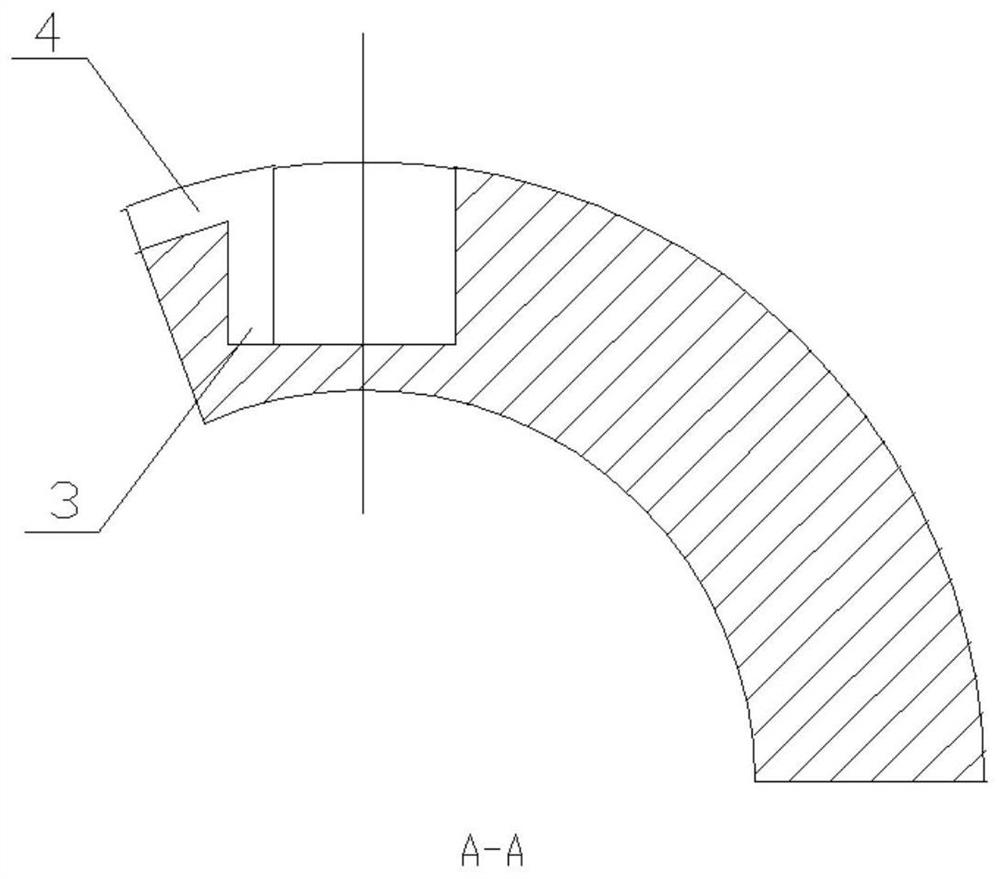

[0049] A gun drill for deep hole processing installed with piezoelectric ceramic materials for deviation measurement and deviation correction, the gun drill includes a piezoelectric drill bit and a piezoelectric drill rod;

[0050] A cylindrical piezoelectric ceramic is installed on the piezoelectric drill bit, and the upper surface of the cylindrical piezoelectric ceramic is adhered with a hard alloy protective layer and forms an interference fit with the hole wall. By applying an external voltage, it is radially deformed and aligned with the hole to be processed. Wall phase extrusion pushes the deflected bit back to the correct position;

[0051] Two long tile-shaped piezoelectric ceramics are installed on the front side of the piezoelectric drill pipe, and the long tile-shaped piezoelectric ceramics are used to detect the voltage change caused by the axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com