Plasma combustion-supporting method for engine combustion chamber

A plasma and combustion chamber technology, which is applied in the field of aero-engines, can solve the problem of no plasma combustion-supporting exciter, etc., and achieve the effects of reducing difficulty, ensuring electricity safety, and avoiding ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

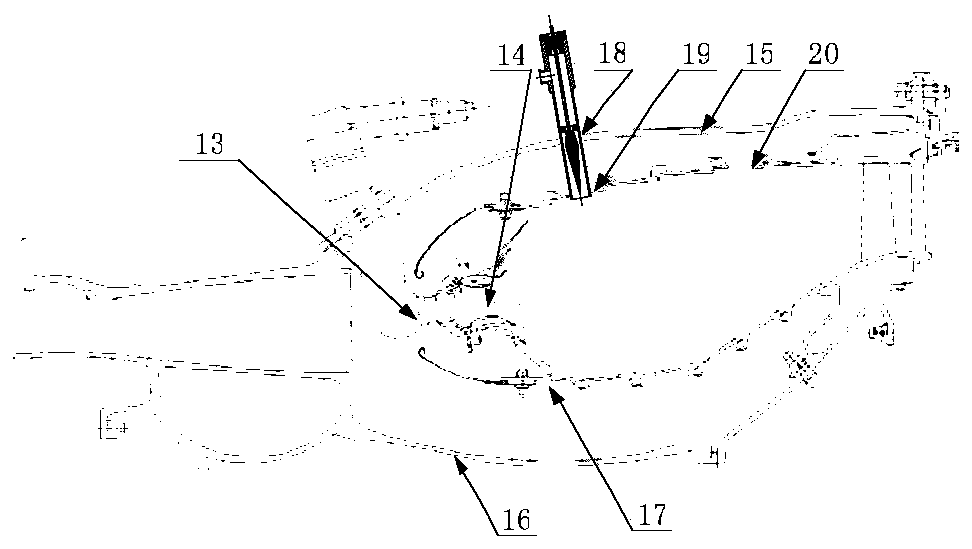

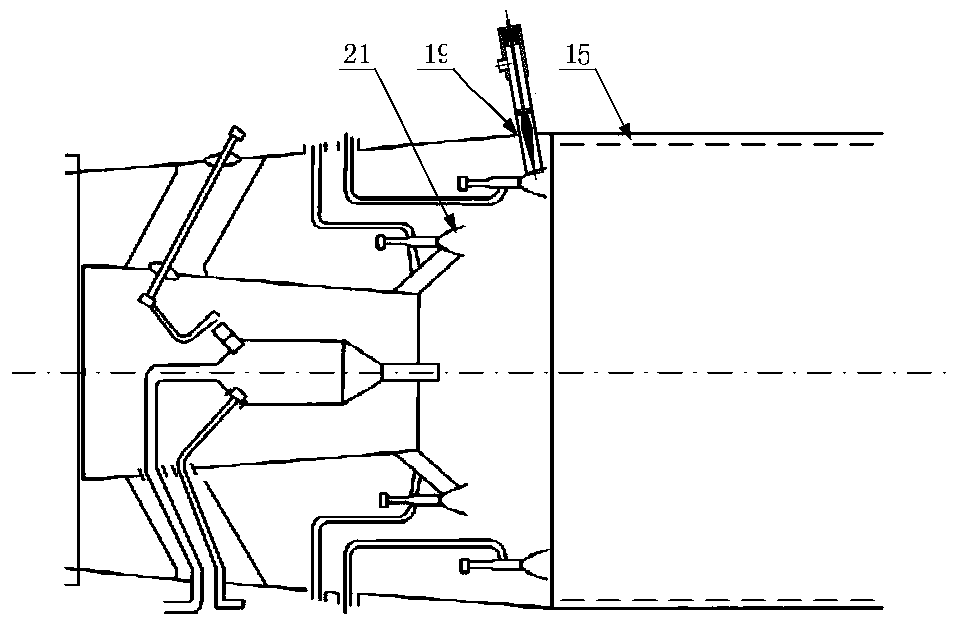

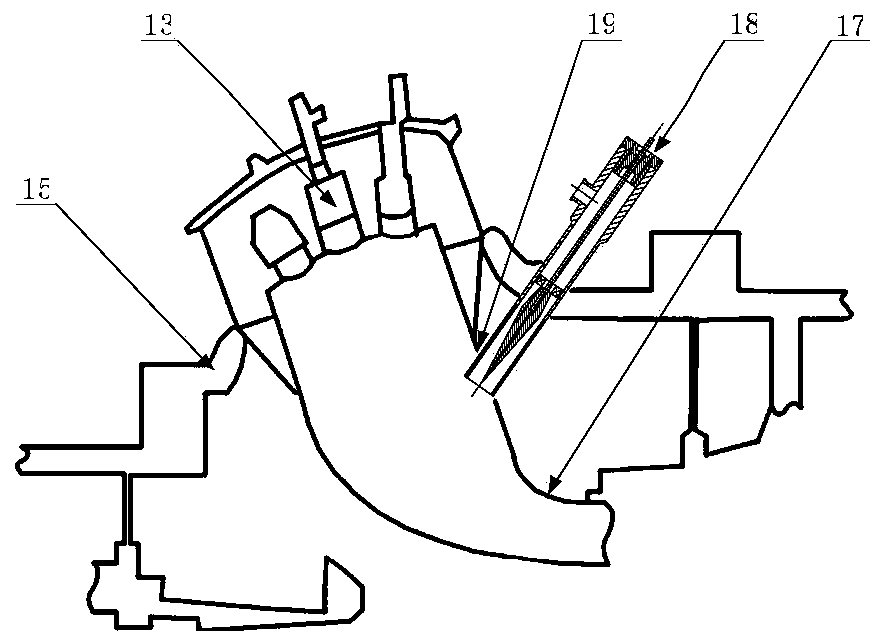

[0051] The invention relates to a plasma combustion-supporting method for a combustion chamber of an engine through a rotary sliding arc plasma combustion-supporting actuator.

[0052] In the present invention, a rotating sliding arc plasma combustion-supporting exciter with rotating sliding arc discharge is adopted. The rotating sliding arc plasma combustion-supporting actuator for rotating sliding arc discharge is disclosed in the invention with the application number 201710204625.3. The structure of the rotating sliding arc plasma combustion-supporting actuator is as follows figure 2 shown. The rotary sliding arc plasma combustion-supporting exciter for the combustion chamber of an aero-engine includes an anode casing, an air inlet nozzle, an electrode installation isolation seat, a cathode electrode rod, an axial flow swirler and a cathode cone electrode; wherein, the shaft The flow cyclone is located in the middle section of the inner hole of the anode casing; the catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com