A method for stripping an optical fiber coating layer and an isolating device

A coating and optical fiber technology, which is applied in the field of optical fiber coating stripping method and device, can solve the problems of difficult precise control of stripping length, scratches on the quartz surface of optical fiber, and uneven cutting surface of optical fiber coating stripping, etc. Achieve the effect of precisely controlling the stripping length, not being prone to severe scratches, and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

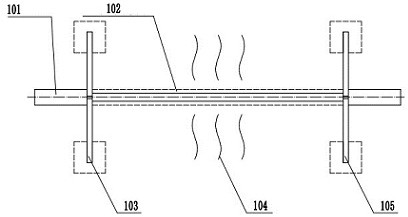

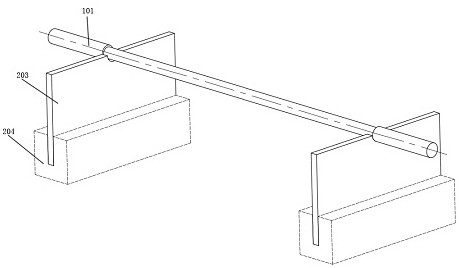

[0023] as attached figure 1 and 2 As shown, the present invention discloses a method for stripping an optical fiber coating, comprising the following steps:

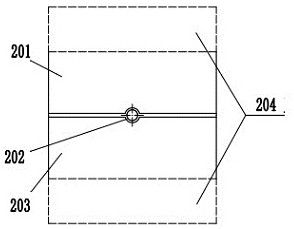

[0024] S1, set up two knife-edge partition devices 103 and 105 on the optical fiber 101, the knife-edge partition device consists of a blade and a mounting frame 204, the blade is mounted on the mounting frame, the optical fiber passes through the blade, and the two knife-edge partitions The distance between the devices is the length of the optical fiber coating to be stripped. According to the length of the optical fiber coating that needs to be stripped, the positions of the two knife-edge partitions can be flexibly installed.

[0025] S2, blow hot air 104 to the optical fiber coating layer 102 between the two knife-edge isolation devices,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com