Real-time calculation method of optimal vacuum of steam turbine

A real-time computing, steam turbine technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as difficulty in ensuring accuracy, and achieve the effect of increasing net income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

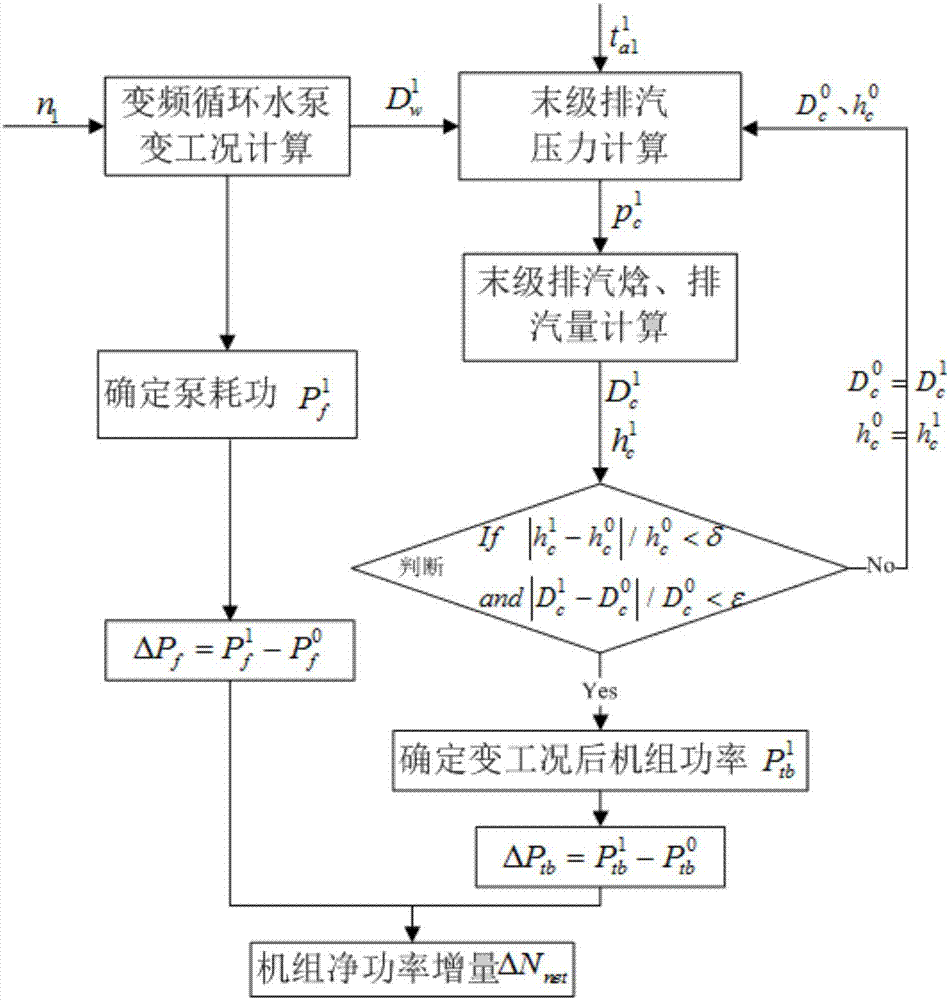

[0015] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0016] The present invention a kind of optimal vacuum real-time computing method of steam turbine, comprises the following steps:

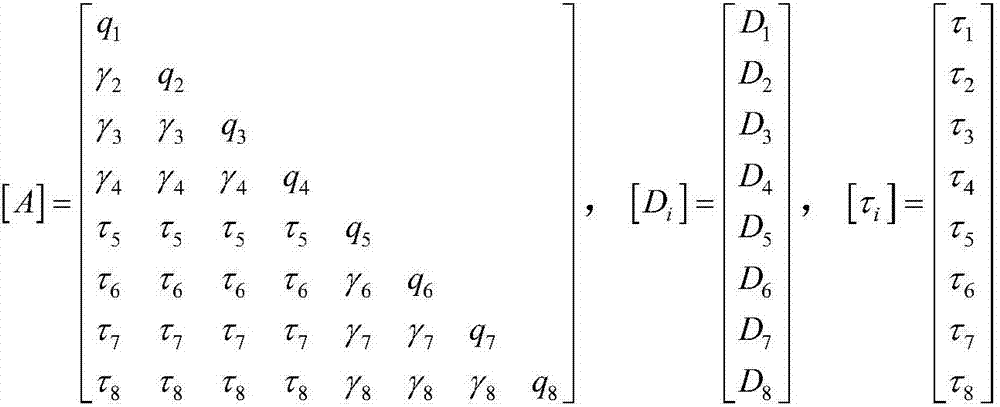

[0017] A: Select the real-time values of the measuring points required in the optimization calculation process from the unit distribution control system (DCS), the measuring points include: main steam flow, main steam temperature, main steam pressure, high-pressure cylinder exhaust temperature, high-pressure cylinder Exhaust steam pressure, reheat steam temperature, reheat steam pressure, steam extraction pressure at all stages of the turbine, extraction steam temperature at all stages of the turbine, water temperature at the outlet of heaters at all stages of the turbine, water pressure at the outlet of heaters at all stages of the turbine, condenser vacuum, Condenser hot well temperature, circulating water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com