In-mold labeling anti-counterfeiting bottle cap and preparation method thereof

A technology of anti-counterfeit bottle caps and bottle caps, which is applied in the field of anti-counterfeiting, can solve the problems of non-existence, loss of appearance and beautification, and easy fading of self-adhesive labels, so as to improve production efficiency, increase power, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

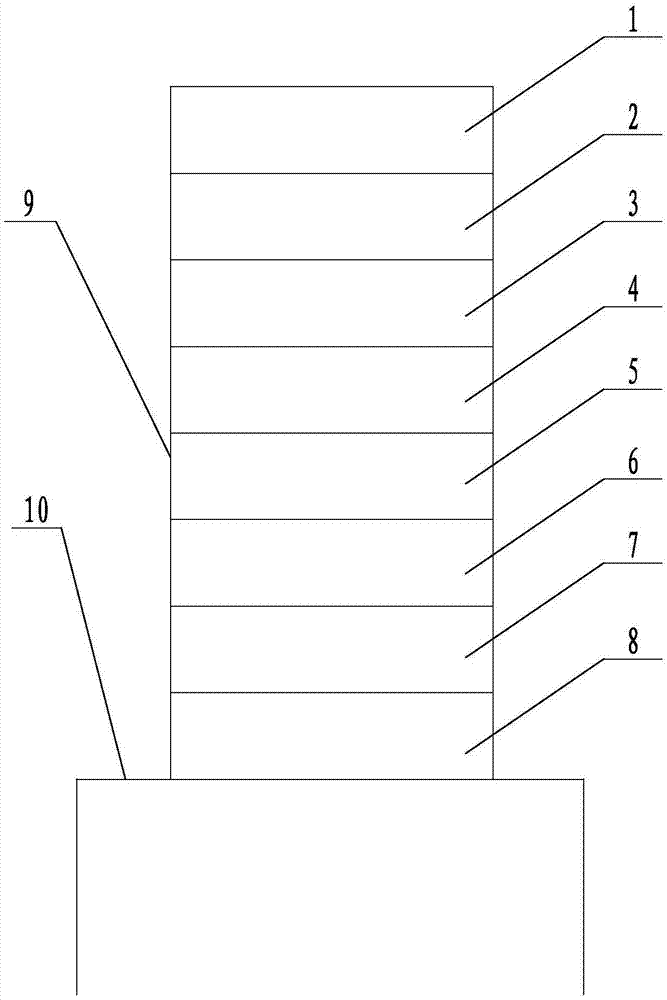

Image

Examples

Embodiment 1

[0036] Customer orders (1 million)

[0037] (1) Selecting a first substrate layer with a thickness of 8 μm;

[0038] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0039] (3) Use two-component glue to combine the first substrate layer and the second substrate layer together, and cure for 24 hours;

[0040] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0041] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0042] (6) Coating meltable glue on the second substrate layer;

[0043] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels;

[0044] (8) Put the anti-counterfeiting label in the mold into the blowing and injection mold cavity. When the mold is closed for blowing and injection, the meltable glue on the anti-counterfeiting la...

Embodiment 2

[0046] Customer orders (2 million)

[0047] (1) Selecting a first substrate layer with a thickness of 50 μm;

[0048] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0049] (3) The first substrate layer and the second substrate layer are composited together using a two-component adhesive, and cured for 36 hours;

[0050] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0051] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0052] (6) Coating meltable glue on the second substrate layer;

[0053] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels;

[0054] (8) Put the anti-counterfeiting label in the mold into the blowing and injection mold cavity. When the mold is closed for blowing and injection, the meltable glue on the anti-cou...

Embodiment 3

[0056] Customer orders (3 million)

[0057] (1) Selecting a first substrate layer with a thickness of 120 μm;

[0058] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0059] (3) The first substrate layer and the second substrate layer are composited together using a two-component adhesive, and cured for 48 hours;

[0060] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0061] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0062] (6) Coating meltable glue on the second substrate layer;

[0063] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels;

[0064] (8) Put the anti-counterfeiting label in the mold into the blowing and injection mold cavity. When the mold is closed for blowing and injection, the meltable glue on the anti-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com