A rotary magnetic fluid generator

A magnetic fluid generator, rotary technology, applied in electromechanical devices, electrical components, etc., to reduce manufacturing costs, improve power coefficient and overall efficiency, and inhibit flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

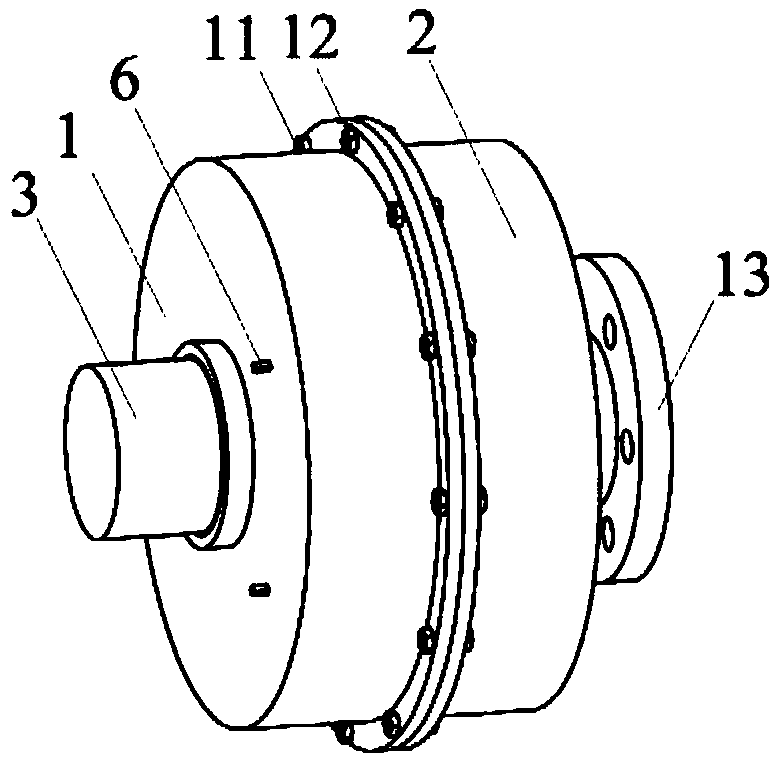

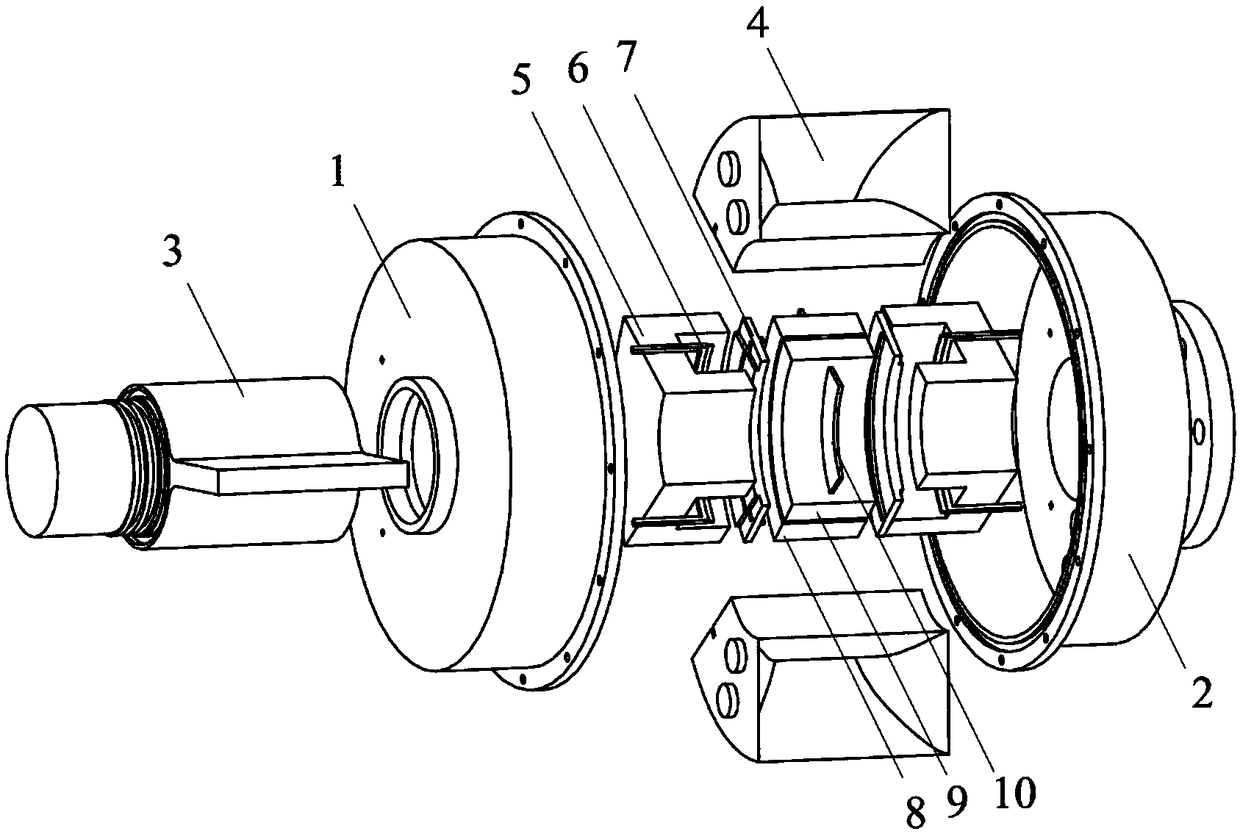

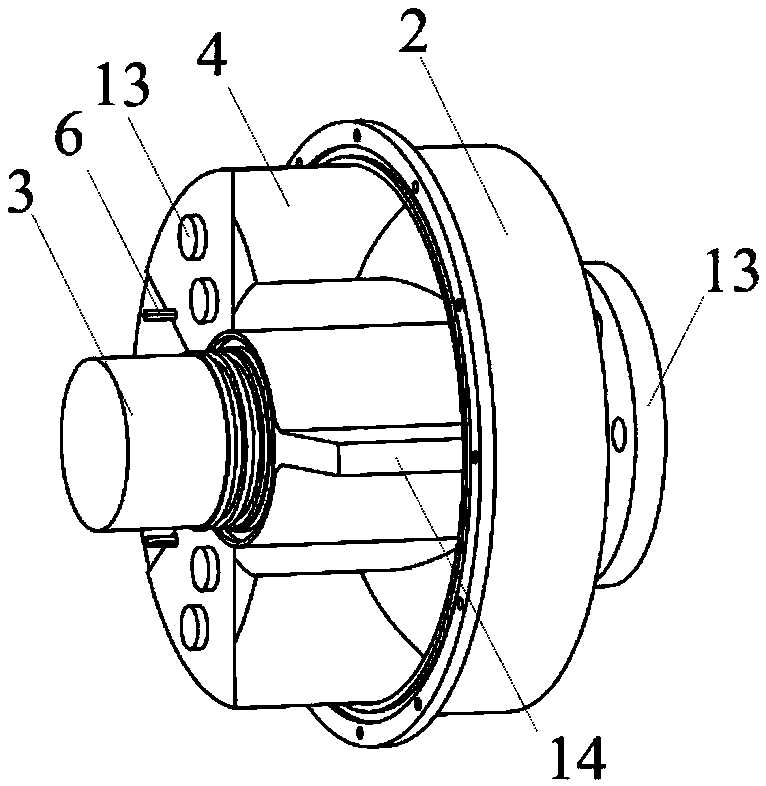

[0025] The appearance diagram and exploded view of the magnetic fluid generator provided by the present invention are shown in figure 1 and figure 2 , the technical scheme adopted is as follows:

[0026] The sealed cylinder is formed by connecting bolts 11 and nuts 12 at the flanges of the first half cylinder 1 and the second half cylinder 2 . The rotating shaft 3 is inserted before the sealing cylinder head cylinder, and the rotating shaft 3 can rotate back and forth in the sealing cylinder. The flanges of the first half cylinder 1 and the second half cylinder 2 and the journal of the rotating shaft 3 are all provided with sealing grooves for sealing the liquid metal in the cylinders. The first half-cylinder 1 and the second half-cylinder 2 are also provided with sealing holes for leading out the collector electrodes 6 . When the end 13 of the second ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com