Sunflower harvesting header

A sunflower and harvesting table technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of multiple operating procedures, high power consumption, and low harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

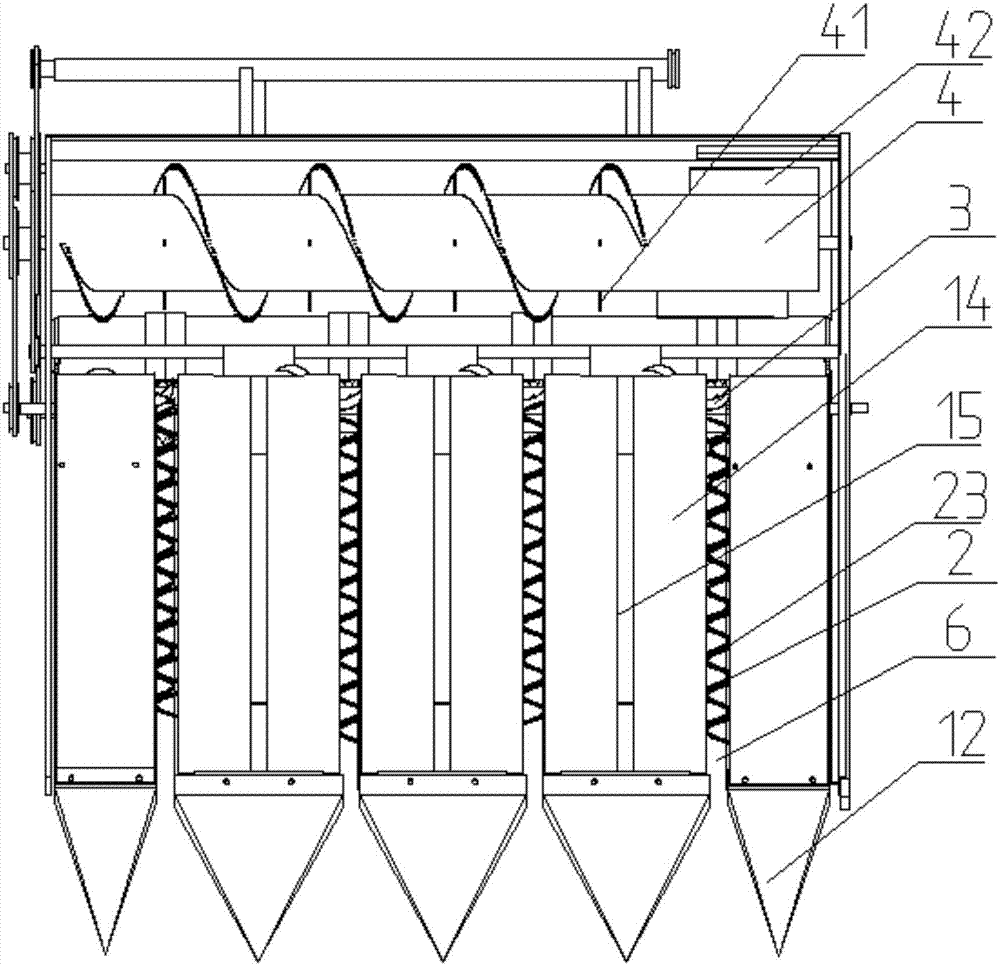

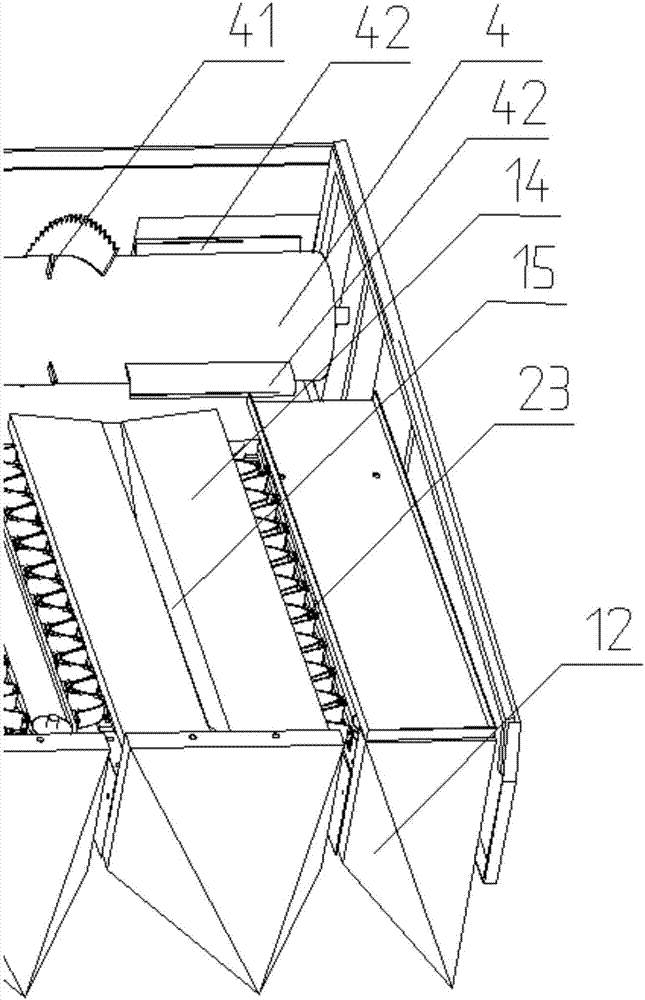

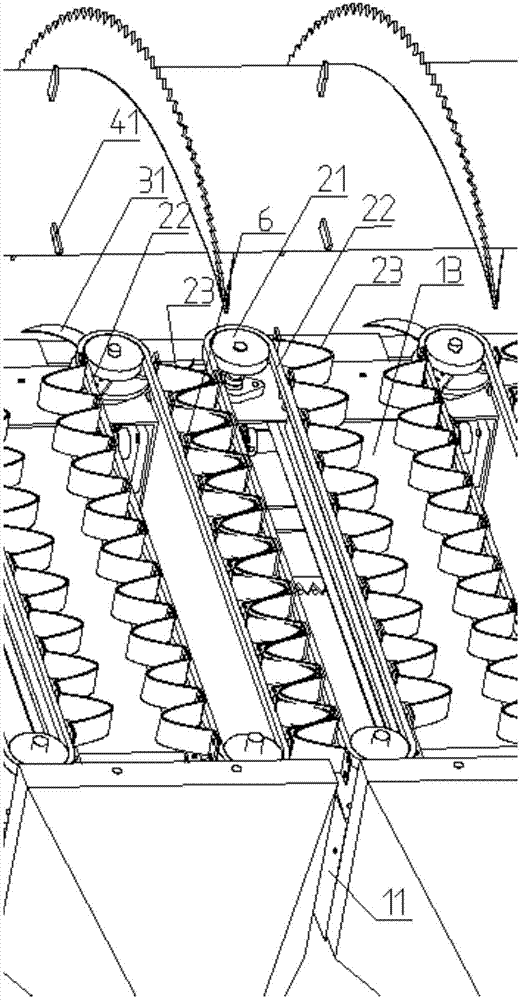

[0024] like Figure 1-Figure 3 As shown, a sunflower harvesting platform includes a grain dividing trough 1, a grain reeling device 2, a grain cutting device 3 and a conveying device 4. The front end of the grain dividing trough 1 is V-shaped, and the grain dividing troughs 1 are equally spaced apart. Arranged in parallel with each other, the gap between the adjacent grain dividing troughs 1 is the grain feeding channel 6, and both sides of the grain feeding channel 6 are provided with a grain reeling device 2, and the grain reeling device 2 includes a sprocket wheel 21 and a reeling device 2 that cooperate with each other. Grass chain 22, the outer peripheral side of the reeling chain 22 is distributed with dialing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com