A kind of preparation method of vitamin C microcapsule and its application in cigarette

A technology of vitamins and microcapsules, applied in the field of cigarette additives, can solve the problems of ineffective use of tobacco formulations, strong volatility and easy decomposition of spices, and achieve the effects of reducing smoke irritation, simple equipment and good application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

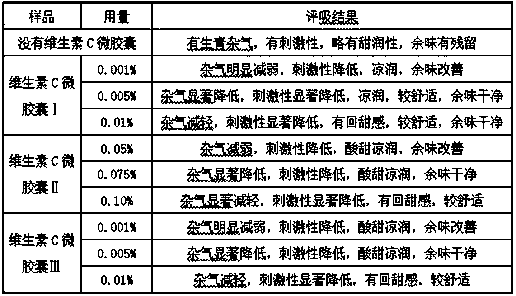

Examples

Embodiment 1

[0029] Weigh 10g of PEG-400 and place it in a flask, add 100g of methanol, fully dissolve it in a water bath at 25°C and mix evenly to obtain a methanol solution containing PEG-400. Weigh 3.33g of edible paraffin, heat the paraffin to melt it completely, add 10g of vitamin C while it is hot and stir evenly to obtain a mixture of vitamin C and edible paraffin. Add the obtained vitamin C and edible paraffin mixture to the PEG methanol solution while hot, and keep stirring at 70°C for 30 minutes. Heating and stirring were stopped, and the mixture was naturally cooled to room temperature under reflux to obtain a suspension containing solids. After the suspension was completely cooled, the supernatant was removed by filtration, and the obtained solid was rinsed with methanol for 3 to 5 times, dried under reduced pressure, and then freeze-dried to obtain 11 g of vitamin C microcapsules I.

Embodiment 2

[0031] Weigh 10g of PEG-400 and place it in a flask, add 250g of methanol, fully dissolve it in a water bath at 35°C and mix evenly to obtain a methanol solution containing PEG-400. Weigh 10 g of edible paraffin, heat the paraffin to melt it completely, add 20 g of vitamin C while it is hot and stir evenly to obtain a mixture of vitamin C and edible paraffin. Add the obtained vitamin C and edible paraffin mixture to the PEG methanol solution while hot, and keep stirring at 70°C for 60 minutes. Heating and stirring were stopped, and the mixture was naturally cooled to room temperature under reflux to obtain a suspension containing solids. After the suspension was completely cooled, the supernatant was removed by filtration, and the obtained solid was rinsed with methanol for 3 to 5 times, dried under reduced pressure, and then freeze-dried to obtain 17 g of vitamin C microcapsule II.

Embodiment 3

[0033] Weigh 10g of PEG-400 and place it in a flask, add 150g of methanol, fully dissolve it in a water bath at 30°C and mix evenly to obtain a methanol solution containing PEG-400. Weigh 5 g of edible paraffin, heat the paraffin to melt it completely, add 15 g of vitamin C while it is hot and stir evenly to obtain a mixture of vitamin C and edible paraffin. Add the obtained vitamin C and edible paraffin mixture to the PEG methanol solution while hot, and keep stirring at 70°C for 45 minutes. Heating and stirring were stopped, and the mixture was naturally cooled to room temperature under reflux to obtain a suspension containing solids. After the suspension was completely cooled, the supernatant was removed by filtration, and the obtained solid was rinsed with methanol for 3 to 5 times, dried under reduced pressure, and then freeze-dried to obtain 19 g of vitamin C microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com