Preparation method of kiwi fruit extracts and application of kiwi fruit extracts in cigarettes

A technology of kiwi fruit and extract, which is applied in the field of cigarette additives to achieve obvious effects, simple equipment, and the effect of improving fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

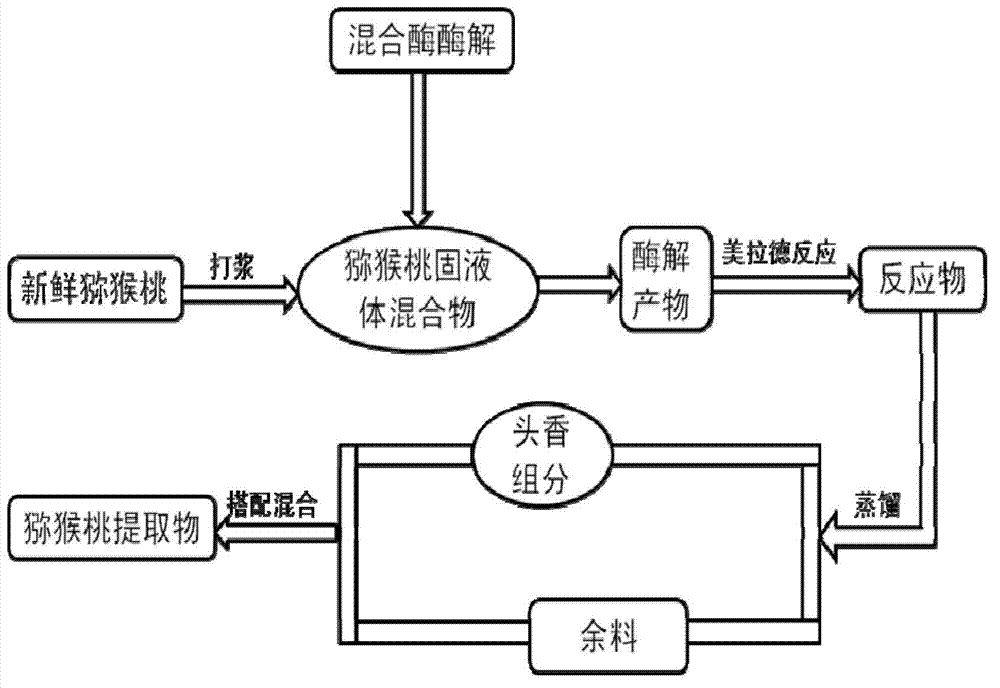

Method used

Image

Examples

Embodiment 1

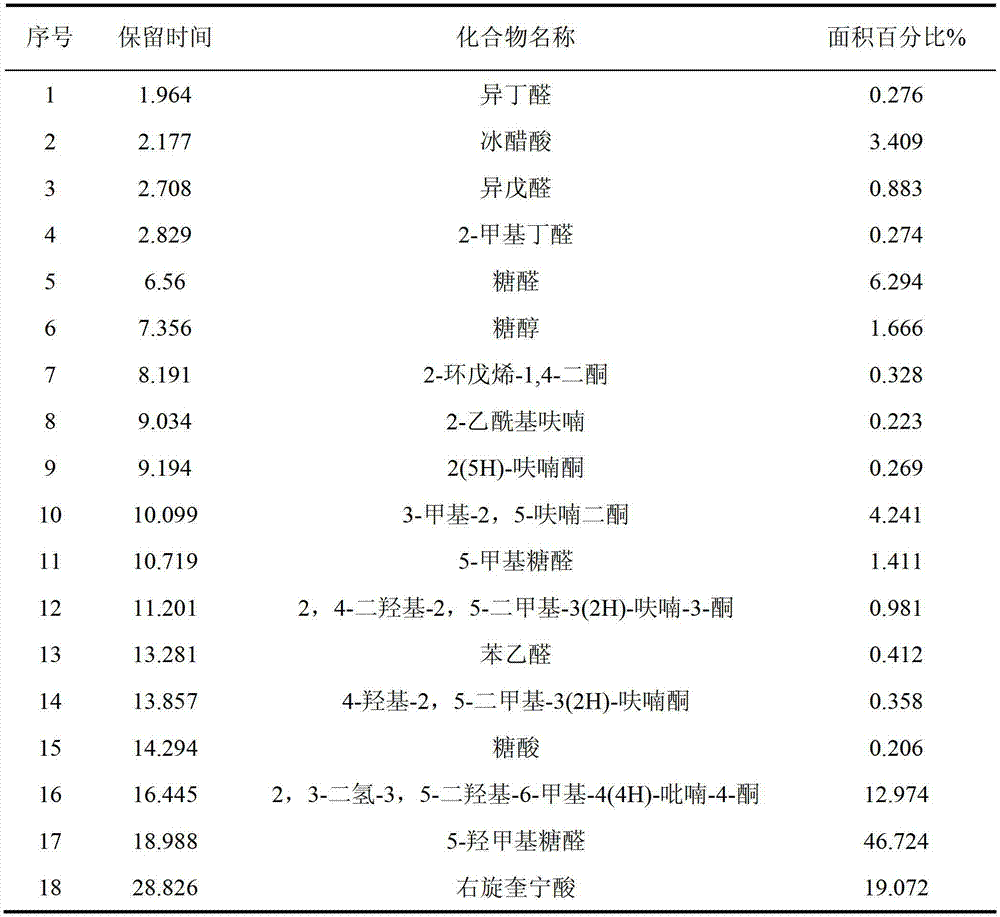

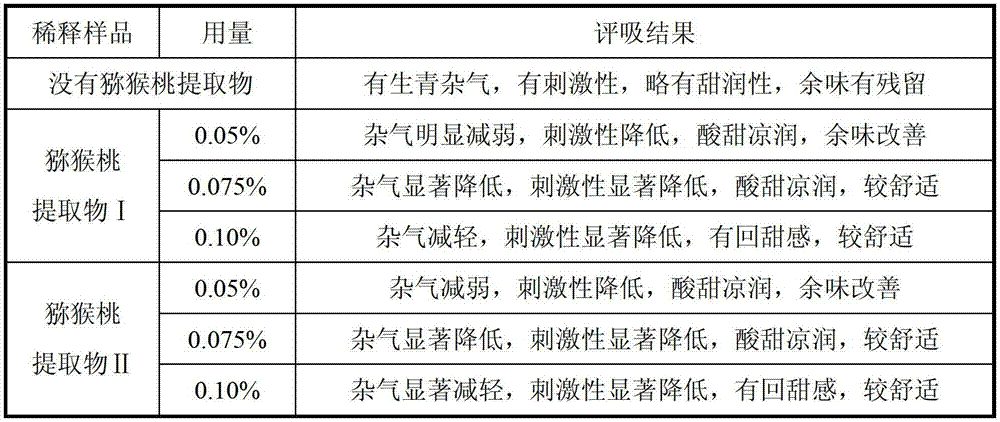

[0024] Accurately weigh 2KG kiwi fruit, put it into a juicer for beating and crushing, add 2000g of 10% mixed enzyme aqueous solution, the mass ratio of the mixed enzyme is pectinase: cellulase: glucoamylase: α-amylase: acid Protease = 2:1:1:1:2, select temperature 37±1°C for constant temperature enzymatic hydrolysis for 2 hours, raise the temperature to 80°C and keep it for 20 minutes to inactivate. The pH of the mixture after deactivation was adjusted to 3.5, and a Maillard reaction was carried out at 20° C. for 18 hours to obtain a reaction mixture. The obtained reaction mixture was distilled, and fractions were collected to obtain 84 g of volatile top-note components. The residue after distillation was extracted with 33% ethanol aqueous solution, and the supernatant was concentrated to obtain 23 g of latent aroma components. The top aroma component and the latent aroma component were mixed according to the mass ratio of 4:1, refrigerated at 2°C for 8 hours, and the superna...

Embodiment 2

[0028] Accurately weigh 2KG kiwi fruit, put it into a juicer for beating and crushing, add 2000g of 10% mixed enzyme aqueous solution, the mass ratio of the mixed enzyme is pectinase: cellulase: glucoamylase: α-amylase: acid Protease = 3:1:2:6:3, select temperature 37±1°C for constant temperature enzymatic hydrolysis for 3 hours, raise the temperature to 90°C and keep it for 20 minutes to inactivate. The pH of the mixture after deactivation was adjusted to 5.8, and a Maillard reaction was carried out at 85° C. for 48 hours to obtain a reaction mixture. The obtained reaction mixture was distilled, and fractions were collected to obtain 64 g of volatile top-note components. The residue after distillation was extracted with 33% propylene glycol aqueous solution, and the supernatant was concentrated to obtain 27 g of latent aroma components. The top aroma component and the latent aroma component were mixed according to the mass ratio of 7:1, refrigerated at 5°C for 12 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com