Colour selector

A color sorter and fan technology, applied in the field of color sorters, can solve the problems of time-consuming, troublesome maintenance, and reduced service life of light source equipment, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

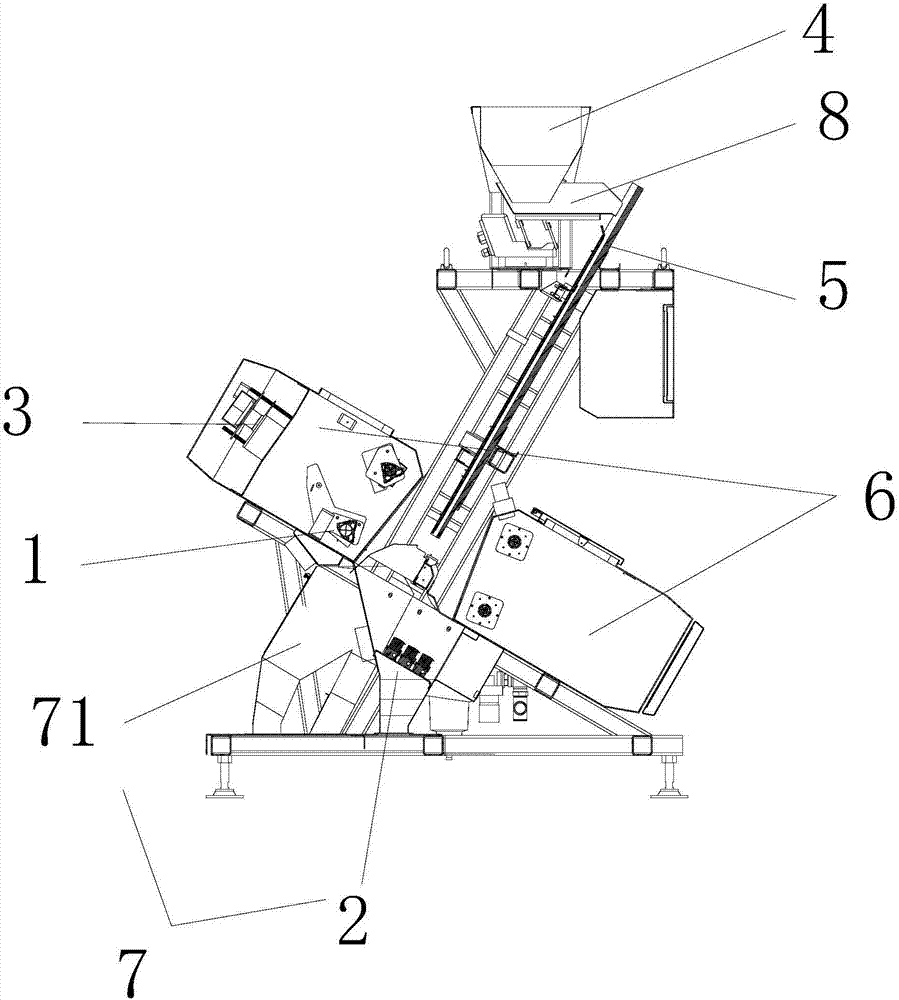

[0046] Such as figure 1 As shown, a color sorter of this embodiment includes a feed hopper 4, a slideway 5, a sorting device 6 and a material receiving device 7; There is a slideway 5, and the slideway 5 is arranged obliquely along the vertical direction of the color sorter, and extends downward to between the two sorting devices 6, and a material receiving device 7 is arranged below the two sorting devices 6. Wherein, the sorting device 6 includes a light source cooling device 1 and a mirror adjustment device 3 at its back end, and the material receiving device 7 includes a front receiving hopper 71 and a rear receiving hopper 2 located at the rear end of the front receiving hopper 71 and used to collect leakage .

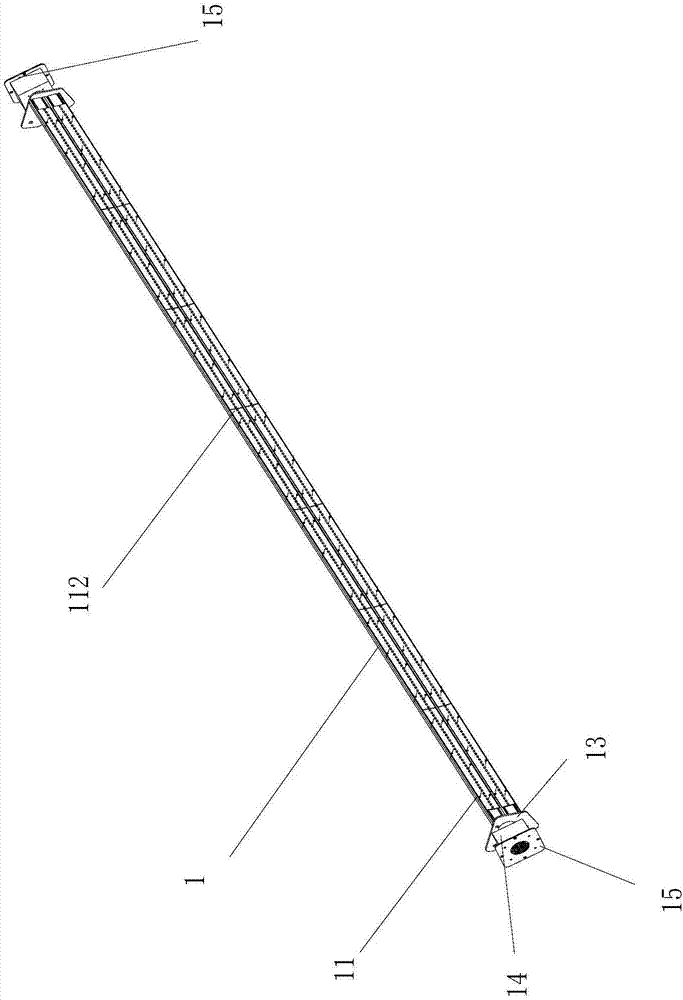

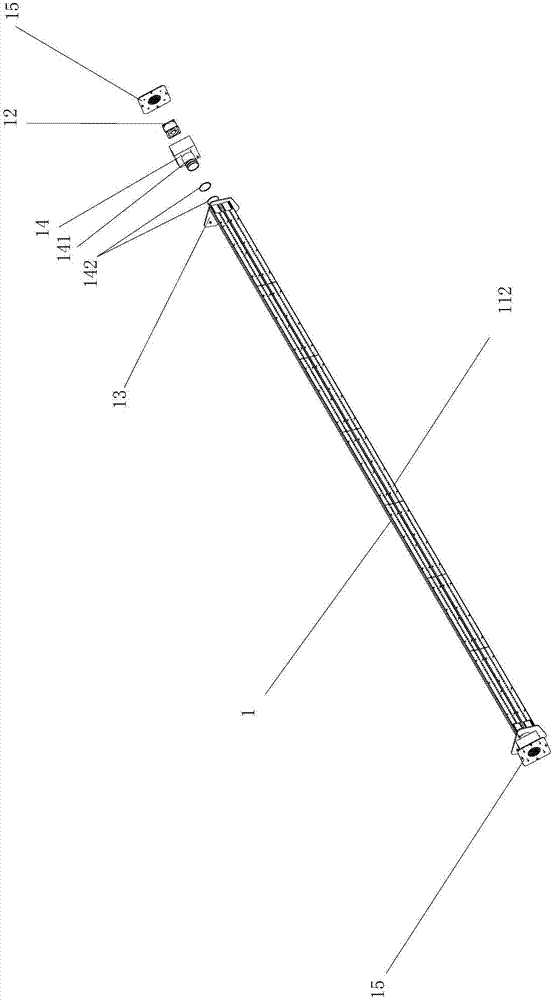

[0047] Such as Figure 2-5 As shown, the light source cooling device 1 includes a lamp holder 11, a fan 12 and an installation side plate 13 between them.

[0048] The lamp holder 11 is specifically an aluminum alloy tubular lamp holder with a circular through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com