Motorcycle throttle body machining fixture

A throttle body and motorcycle technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low equipment utilization rate, long processing cycle, waste products, etc., to improve the utilization rate of machine tools, improve Parts qualified rate, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

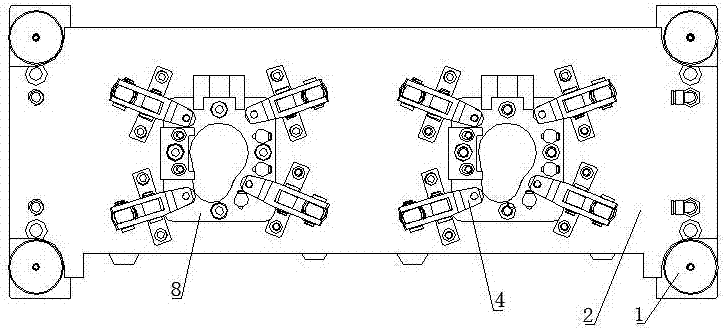

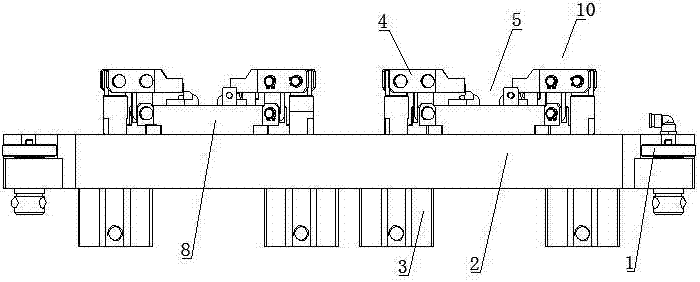

[0021] Such as Figure 1~Figure 4 As shown, a motorcycle throttle body processing fixture includes a ball joint locking and positioning mechanism 1, a bridge plate 2, a clamp positioning unit 5 and a pressing unit 10, and the two ends of the bridge plate 2 pass through the ball joint locking and positioning mechanism 1 They are respectively connected to the tailstock on the machine tool and the L plate of the indexing head, and the bridge plate 2 is provided with two fixture positioning units 5 and multiple pressing units 10;

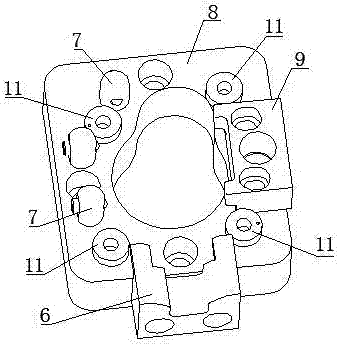

[0022] Specifically, the clamp positioning unit 5 includes a clamp base 8, a positioning block A6, a moving steel ball screw assembly 7 and a positioning block B9, the clamp base 8 is fixed on the bridge plate 2 by screws, and the bridge plate 2 and the clamp base 8 There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com