Log squarer with saw dust collecting and drying functions

A technology for a square cutter and sawdust, which is applied to the field of log square machines with the function of collecting and drying sawdust, can solve the problems of not being able to collect sawdust and dust, not setting a sawdust drying cylinder, and not setting an electric telescopic rod, etc. Reduce drying time, improve reusability, and avoid the effect of not easy to pour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

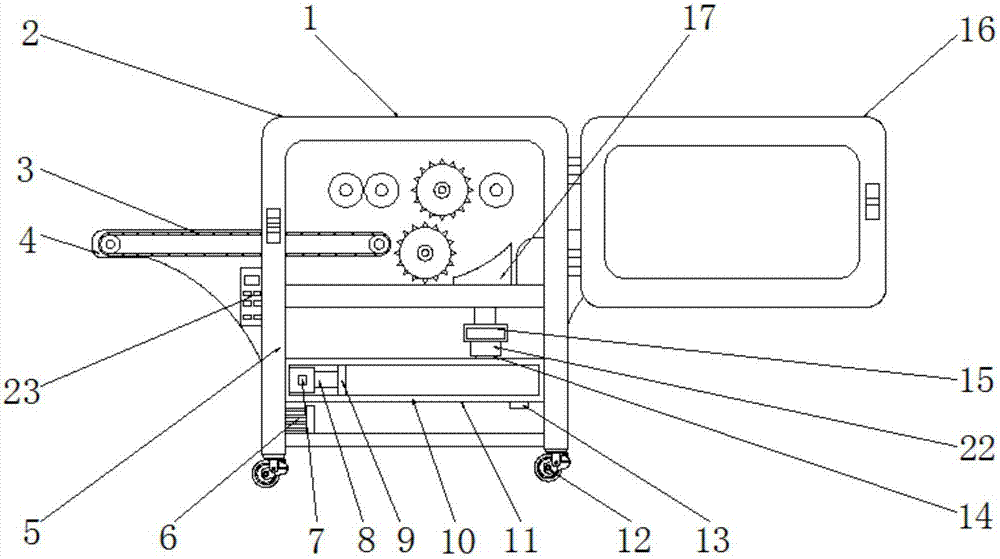

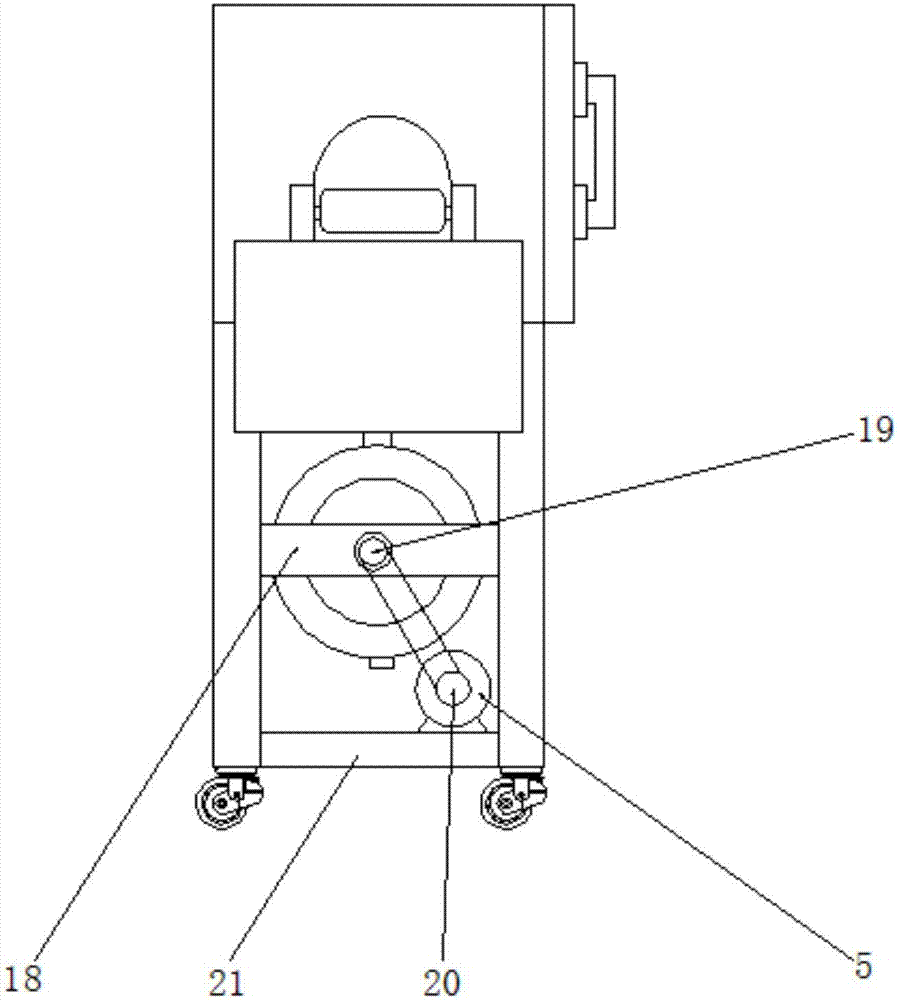

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a log squarer with the function of collecting and drying sawdust, including a log development machine body 1, a cutting box 2, a conveyor belt 3, a fixed table for a feed port 4, a bracket 5, Motor 6, controller 7, electric telescopic rod 8, push block 9, heating layer 10, sawdust drying cylinder 11, damping wheel 12, discharge port 13, feed port 14, fan 15, side cover 16, sawdust collection Pipe 17, crossbeam 18, driven wheel 19, transmission wheel 20, bottom crossbeam 21, connecting pipe 22 and control switch 23, the outside of log development machine body 1 is provided with cutting box 2, and one side of cutting box 2 is connected with side cover 16 , and one side of the cutting box 2 is provided with a feed inlet fixed table 4, a control switch 23 is installed on one side of the cutting box 2 near the lower side of the feed inlet fixed table 4, and a sawdust collector is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com