Preparation method for polypropylene film

A technology of polypropylene film and polypropylene, which is applied in the chemical industry, can solve problems such as voids in polypropylene films, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of polypropylene film, comprising:

[0023] (1) heating the raw material to 180°C;

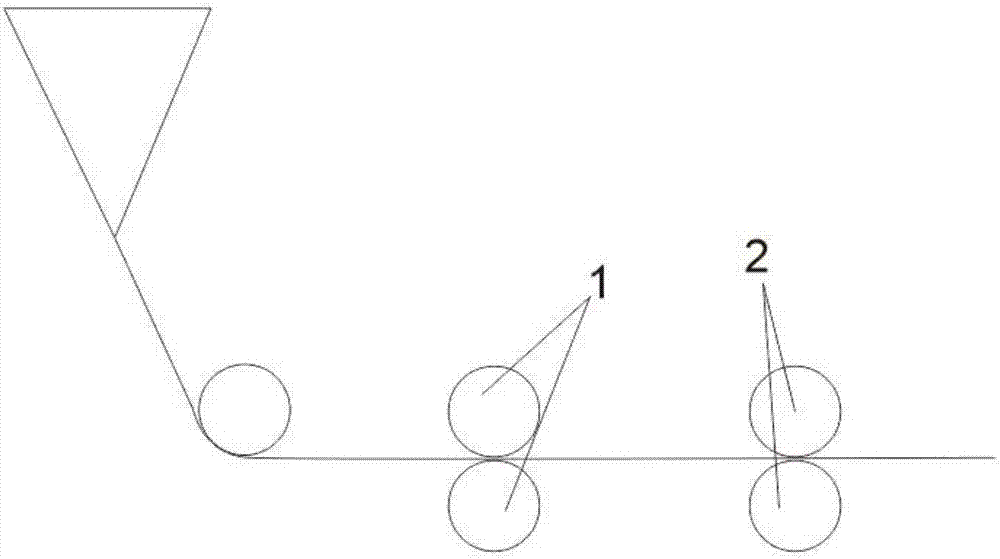

[0024] (2) Roll the heated raw material through the pulley block. The pulley block includes two sets of extruding pulley blocks. The extruding pulley block includes two extruding pulleys facing up and down. Extrusion pulley block 2, the raw material is extruded from two extrusion pulleys, and the gap between the two extrusion pulleys is 1.8mm; the temperature of the raw material is 180°C when it passes through the front extrusion pulley block 1, and after passing through the rear extrusion pulley block 2 The temperature at the time is 150°C;

[0025] (3) Gradually lower the temperature to normal temperature, wind up and store.

[0026] Among them, the ratio of raw materials is 30% of polypropylene, 60% of calcium carbonate, 5% of silicon dioxide, and 5% of kaolin. Polypropylene is the main film-forming substance. Calcium carbonate can adjust the degradation time ...

Embodiment 2

[0028] A preparation method of polypropylene film, comprising:

[0029] (1) heating the raw material to 160°C;

[0030] (2) Roll the heated raw material through the pulley block. The pulley block includes two sets of extruding pulley blocks. The extruding pulley block includes two extruding pulleys facing up and down. Extrusion pulley block 2, the raw material is extruded from two extrusion pulleys, and the gap between the two extrusion pulleys is 0.2mm; the temperature of the raw material is 160°C when it passes through the front extrusion pulley block 1, and after passing through the rear extrusion pulley block 2 The temperature at the time is 120°C;

[0031] (3) Gradually lower the temperature to normal temperature, wind up and store.

[0032] Among them, the ratio of raw materials is 85% of polypropylene, 8% of calcium carbonate, 3% of silicon dioxide, and 4% of kaolin.

Embodiment 3

[0034] A preparation method of polypropylene film, comprising:

[0035] (1) heating the raw material to 170°C;

[0036] (2) Roll the heated raw material through the pulley block. The pulley block includes two sets of extruding pulley blocks. The extruding pulley block includes two extruding pulleys facing up and down. Extrusion pulley block 2, the raw material is extruded from two extrusion pulleys, and the gap between the two extrusion pulleys is 0.8mm; the temperature of the raw material is 160°C when it passes through the front extrusion pulley block 1, and after passing through the rear extrusion pulley block 2 The temperature at the time is 130°C;

[0037] (3) Gradually lower the temperature to normal temperature, wind up and store.

[0038] Among them, the ratio of raw materials is 70% of polypropylene, 20% of calcium carbonate, 5% of silicon dioxide, and 5% of kaolin.

[0039] The polypropylene film obtained in Example 1 can be used for the preparation of environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com