Method for preparing high-porosity three-dimensional calcium alginate gel scaffolds by virtue of pulsed ultrasonic wave

A technology of three-dimensional calcium alginate and pulsed ultrasound, which is applied in the direction of tumor/cancer cells, vertebrate cells, animal cells, etc., can solve the problems of organic solvent residue and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

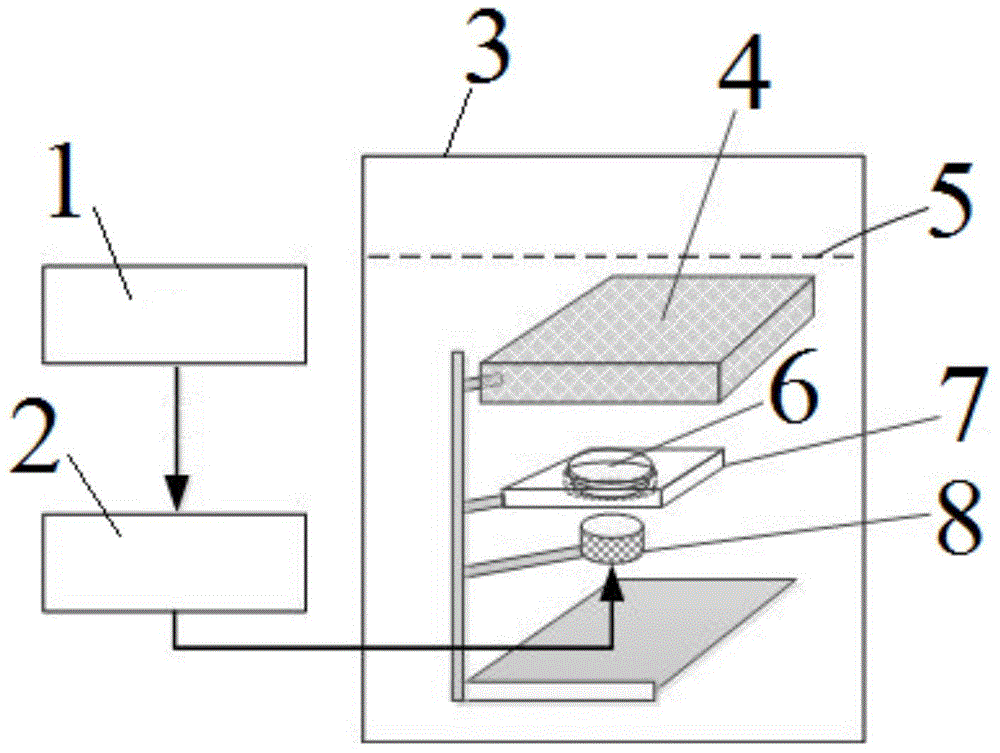

[0032] In conjunction with the accompanying drawings, a method of using pulsed ultrasound to prepare a three-dimensional calcium alginate gel scaffold with large porosity in this embodiment, the specific steps are as follows:

[0033] Step 1. Using the cross-linking synthesis method to directly shape calcium alginate three-dimensional gel scaffolds with different mechanical strengths:

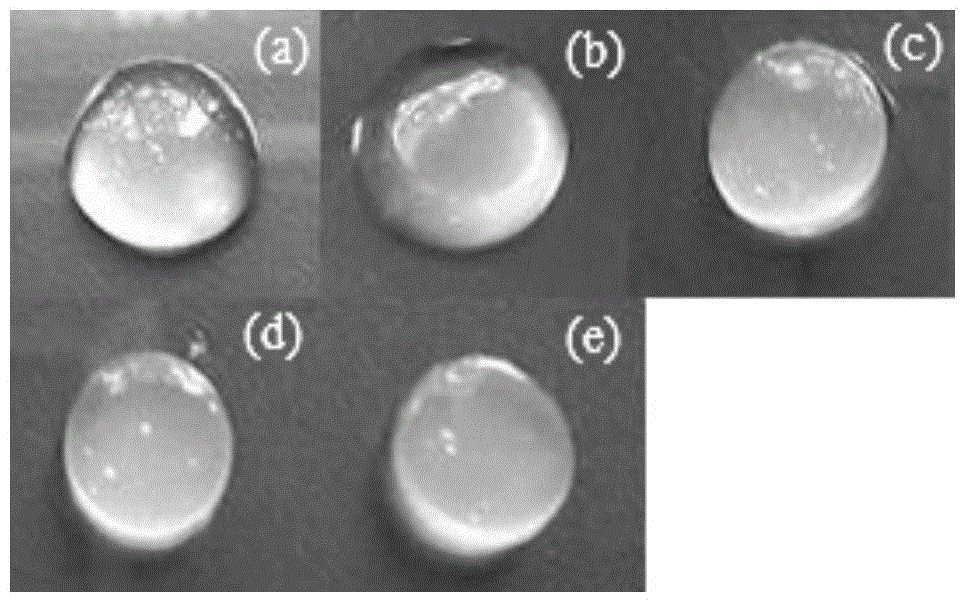

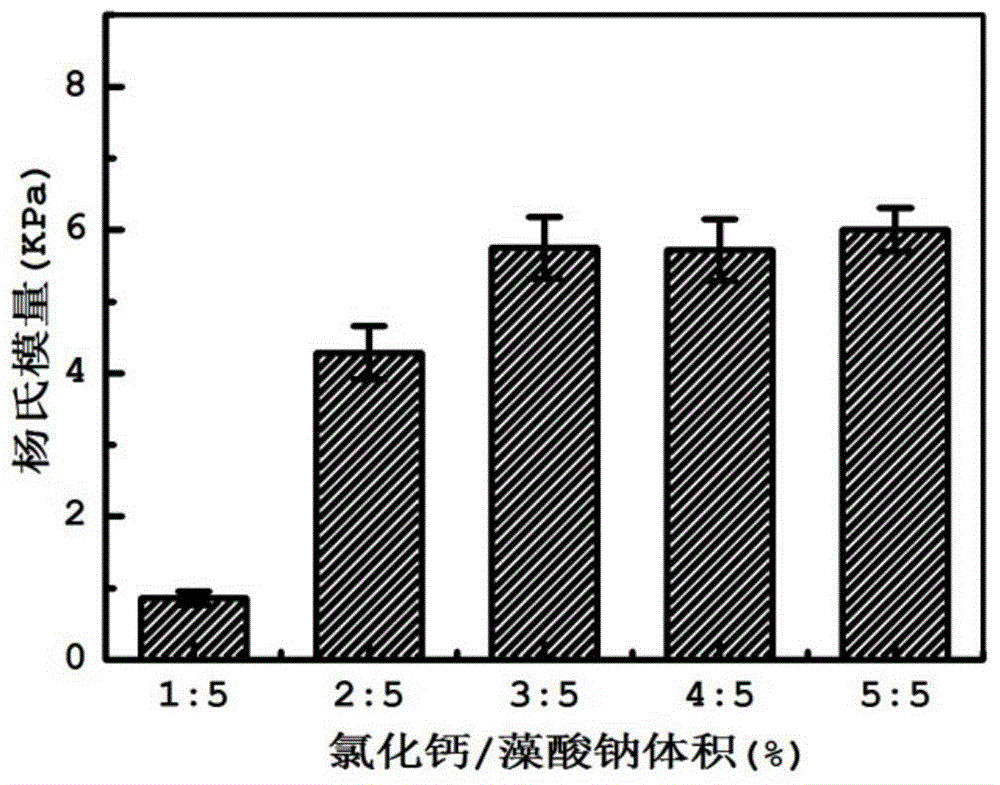

[0034] 1.132g calcium chloride (CaCl 2 ) pure product was dissolved in 100ml deionized pure water, stirred evenly to obtain a 102mmol / L calcium chloride solution, and stored at 4°C. The pure sodium alginate was dissolved in deionized pure water to obtain a 1.2% w / v solution, which was stored at 4°C. The calcium chloride solution with volumes of 100 μl, 200 μl, 300 μl, 400 μl and 500 μl and 500 μl of 1.2% sodium alginate solution were stirred by a vortex mixer, and mixed quickly and thoroughly at a speed of 1800 r / min for 20 seconds in a 15 ml centrifuge tube. The well-mixed solution was place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com