Laser transmission welding clamping system for automobile lamp and method of laser transmission welding clamping system

A technology of laser transmission welding and laser emission system, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of laser transmission welding clamping device, poor optical performance of glass balls, and surface wear of glass balls. Achieve the effects of improving welding efficiency and welding quality, saving manpower and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

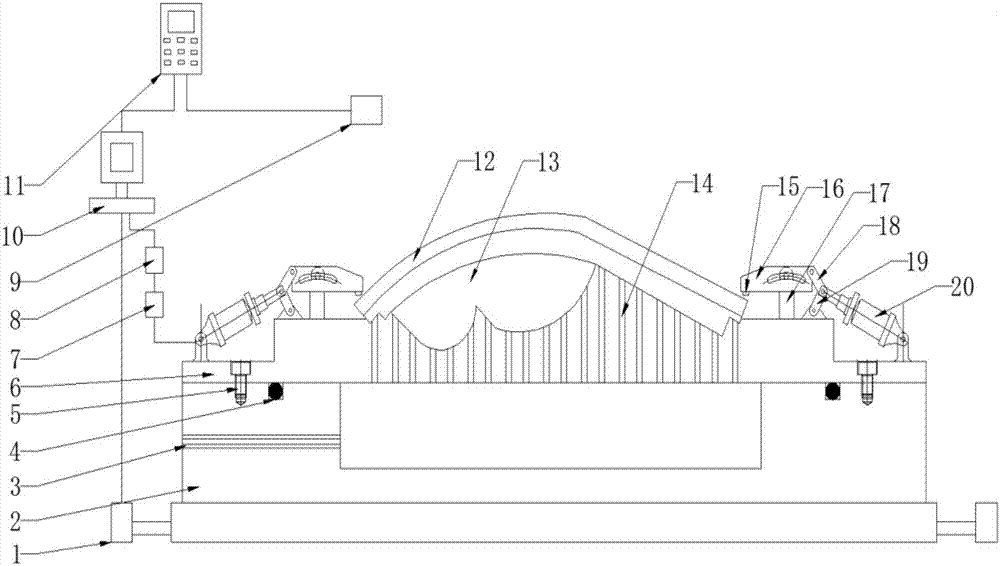

[0036] combined with figure 1 As shown, a laser transmission welding clamping system for automobile lights, including a laser emitting system, a clamping system and a control system;

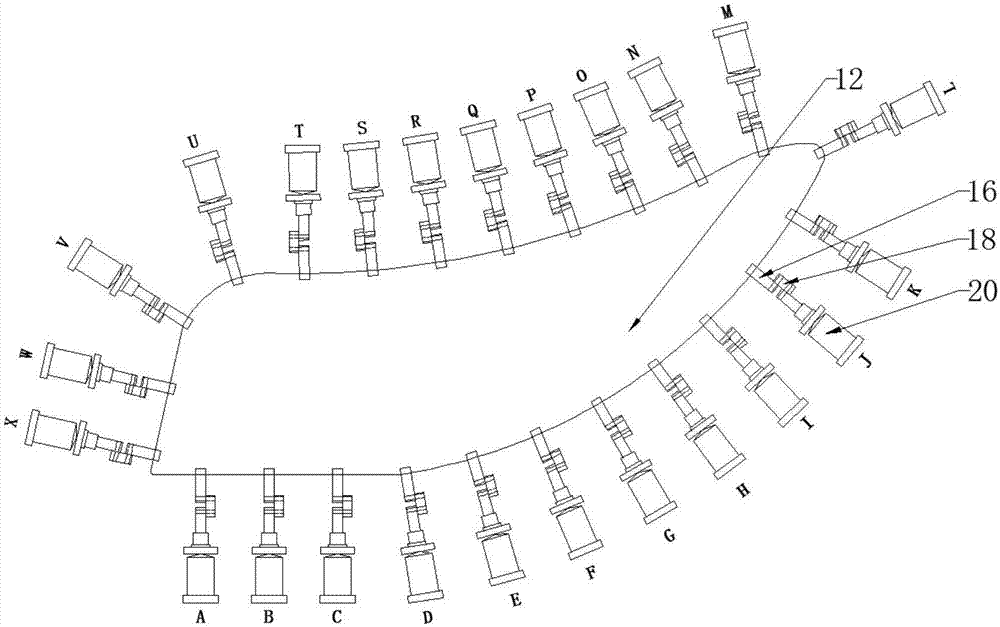

[0037] Described laser emission system comprises laser emitter 9, laser controller 11 and mechanical arm; Described laser controller 11 controls laser emitter 9; Described laser emitter 9 is positioned on the mechanical arm, through the mechanical arm The movement drives the laser transmitter 9 to realize the three-dimensional welding of the headlights;

[0038] The clamping system includes a vacuum device and a clamping device;

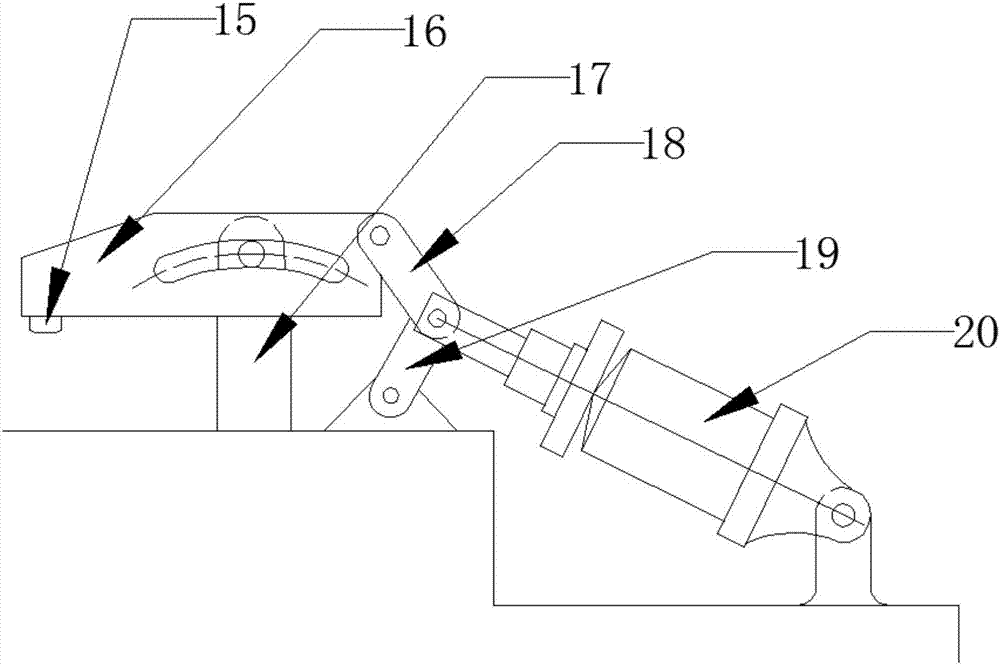

[0039] The vacuum device includes an upper plate 6, an air extraction through hole II14, a base 2, an air extraction through hole I3 and a vacuum generator; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com