System and method for sectional pH (potential of hydrogen) value adjusting of thermal system of thermal power plant

A thermal system and system adjustment technology, applied in chemical instruments and methods, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problems of accelerated flow corrosion, high scaling rate of boiler heating surface, etc., to reduce the content, The effect of improving safety and economy and slowing down the fouling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

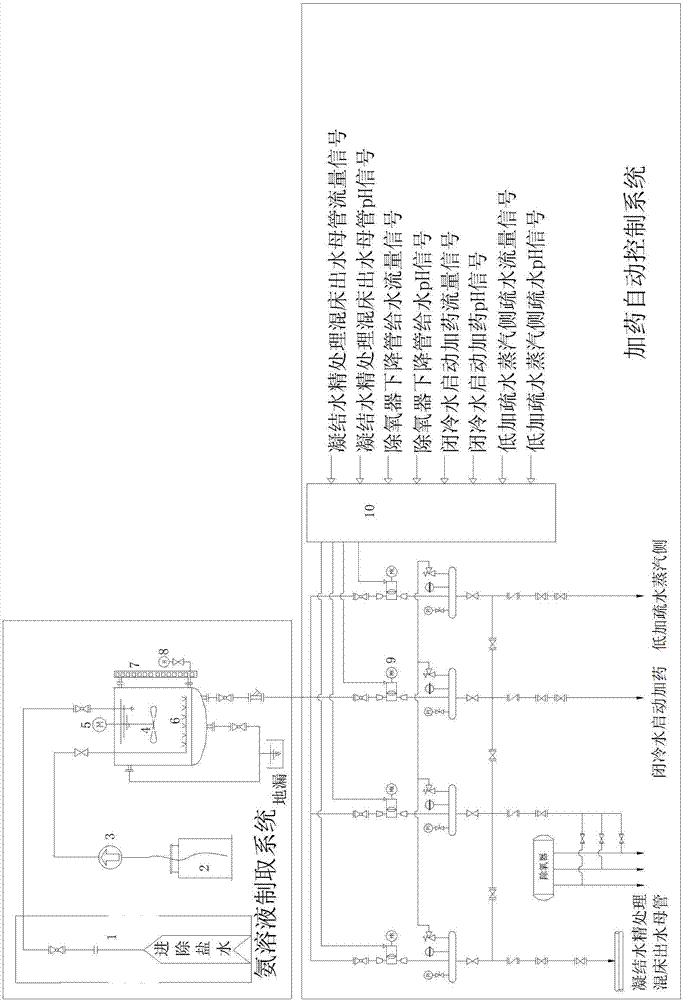

[0020] Such as figure 1 As shown, the segmented pH adjustment system of the thermal power system of the present embodiment includes: an ammonia solution preparation system and an automatic dosing control system, the ammonia solution preparation system includes an ammonia solution tank 6, and the liquid inlet of the ammonia solution tank The desalted water incoming water pipeline 1 and the strong ammonia water barrel pipeline 2 respectively connected, the strong ammonia water barrel delivery pump 3 is provided on the strong ammonia water barrel pipeline, the ammonia solution tank agitator 4 is arranged in the ammonia solution tank, the The ammonia solution box top is provided with the ammonia solution box stirring motor 5 that drives the ammonia solution box agitator, and the water outlet of the ammonia solution box is connected with the water outlet pipeline; The metering pump on the water outlet pipeline, the metering pump 9 is electrically connected to the PLC controller, an...

Embodiment 2

[0025] The segmented pH adjustment method of the thermodynamic system of the thermal power plant in this embodiment utilizes the above-mentioned system, and the method includes:

[0026] Step 1: The ammonia solution preparation system prepares the ammonia solution: the demineralized water supply line 1 enters the top of the ammonia solution tank 6, and at the same time, the concentrated ammonia water from the concentrated ammonia water barrel pipeline 2 is transported into the ammonia solution tank through the concentrated ammonia water barrel delivery pump 3 The bottom of 6 is mixed with the incoming water in the desalted water supply pipeline 1, and the ammonia solution tank stirring motor 5 arranged on the upper part of the ammonia solution tank 6 drives the ammonia solution tank agitator 4 to rotate, mixing the desalted water and the concentrated ammonia solution; The sensor 8 automatically controls the ammonia solution tank 6 to maintain a certain liquid level;

[0027] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com