Mobile terminal 3D protective glass cover thermoforming device

A hot-press forming, mobile terminal technology, applied in glass forming, glass re-forming, glass production and other directions, can solve the problems of high mold cost, reduce product quality, increase production cost, etc., to avoid the problem of product yield decline , the effect of improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

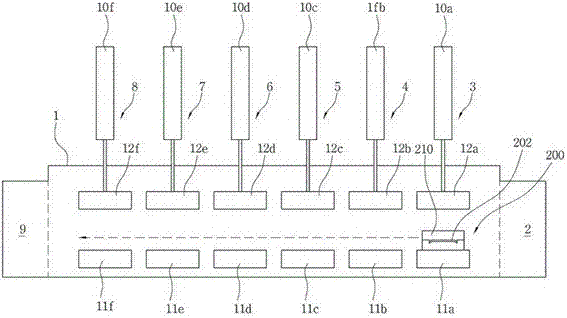

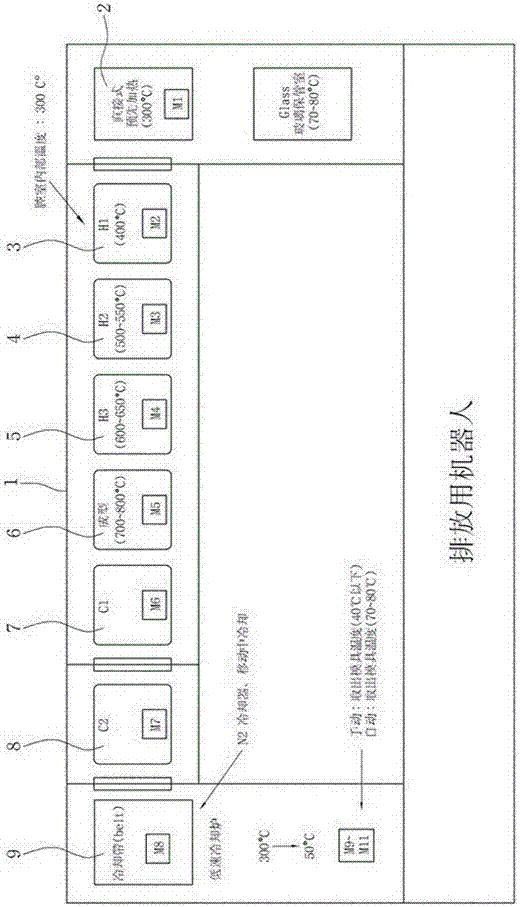

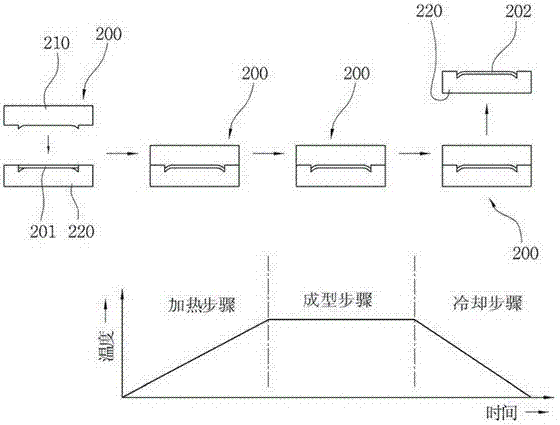

[0064] Such as Figure 1 to Figure 10 As shown in the figure, the mold 200 is sequentially transferred inside the cavity 1 with certain sealing ability and thermal insulation ability, and the mold passes through the auxiliary preheating chamber 2, the first preheating part 3, and the second preheating part in sequence through the conveying mechanism. 4. The third preheating part 5, the forming part 6, the first cooling part 7, the second cooling part 8, and the auxiliary cooling chamber 9, and then carry out staged heating, hot pressing forming and dividing according to the sequence of preheating, forming and cooling. stage cooling.

[0065] The chamber 1 is filled with an inert protective gas whose thermal conductivity is higher than that of pure nitrogen.

[0066] The inert protective gas is a mixed protective gas obtained by mixing nitrogen (N2) and helium (He) in a certain proportion.

[0067] The mold 200 includes a lower mold, an upper mold, and a flat glass 201 made o...

no. 2 example

[0117] Figure 11 A second embodiment of the invention is illustrated, comprising:

[0118] Curved surface molding frame 50 is equipped with curved surface 51 at one or both ends, and the plate-shaped material 52 in the preheated state is placed on the upper surface; fixed part 60 is driven by actuator 61 to move up and down and has the ability to hold the material when forming. 52 is fixed at one end of the fixed rod 62; the pressing part 70 has a pressing piece 72, which is driven by the actuator 71 to move up and down and exerts a biased load on one side of the material 52 during molding, so that the material 52 and the curved surface Part 51 is in close contact to realize curved surface molding.

[0119] The second embodiment constituted in this way does not use a mold body composed of upper and lower molds, but utilizes a curved surface forming frame 50 with an open top to bend and shape the curved surface of the cover glass.

[0120] The fixing part 60 and the pressuri...

no. 3 example

[0124] Figure 12 A third embodiment of the invention is illustrated, comprising:

[0125] Curved surface molding frame 50 is equipped with curved surface 51 at one or both ends, and the plate-shaped material 52 in the preheated state is placed on the upper surface; fixed part 60 is driven by actuator 61 to move up and down and has the ability to hold the material when forming. One end of 52 is fixed to the fixed rod 62; Rolling pressing part 80 is provided with pressing roller 82, and it is moved up and down by the actuator 81 that moves along guide piece in the horizontal direction, with close contact material 52 surface during molding The rolling movement of the state makes the material 52 closely contact with the curved surface 51 to realize the forming of the curved surface.

[0126] The fixing part 60 and the rolling pressing part 80 of the third embodiment are also installed inside the sealed chamber not shown in the figure, and the plate shape in the preheating state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com