Tight oil and gas reservoir pressure test process matched device and using method

A technology for oil and gas reservoirs and pressure testing, which is applied in earthwork drilling, wellbore/well components, buildings, etc., can solve problems such as long period, inconvenient operation, and influence of test results, and achieve compact structure, convenient monitoring and supervision, Avoid the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

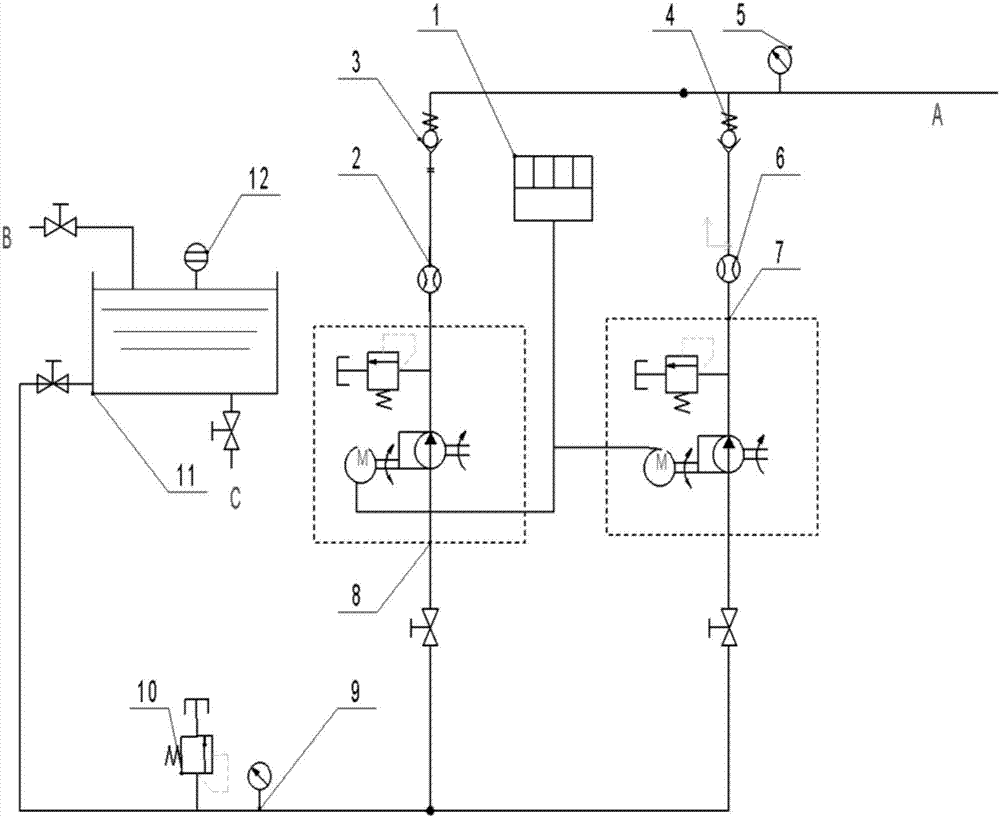

[0020] Such as figure 1 As shown, it includes a large flow pump 8 and a small flow pump 7, and a control and recording system 1 for controlling the start, stop and output flow of the large flow pump 8 and the small flow pump 7. The control and recording system 1 is provided with a device for adjusting The adjustment knob for the flow output of the large flow pump 8 and the small flow pump 7; according to the flow requirements, start the pump with the large flow pump 8 or the small flow pump 7, and pump out the liquid in the liquid storage tank 11 through the manifold after starting the pump from outlet A through the manifold output, each output is provided with a check valve, and an overflow valve 10 and an electronic pressure gauge 9 for monitoring the liquid pressure in the manifold are also installed on the output manifold of the liquid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com