Underwater pipe fitting butting device having direct butting and adjustment functions

A technology of docking device and function, applied in the direction of pipe/pipe joint/pipe fitting, mechanical equipment, pipeline laying and maintenance, etc., can solve the problems such as displacement of flat pipe flange, no direct installation function of subsea flat pipe section, repeated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings of the specification and specific implementations.

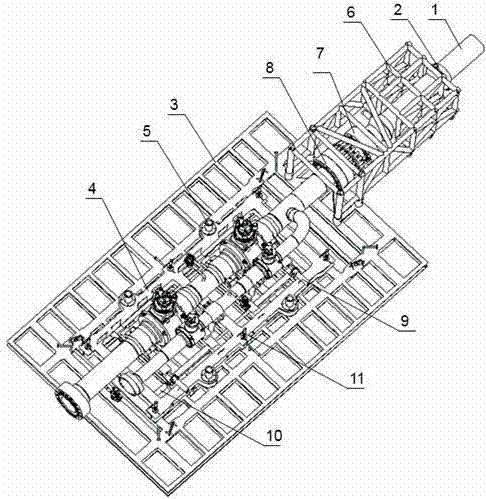

[0019] Such as figure 1 As shown, the underwater pipe docking device with direct docking and adjustment functions described in this embodiment includes a skid base 3, a manifold support frame 4, a manifold, a figure-head guide initial positioning device 6, and a jacking hydraulic cylinder 5. , Rotating flange 7, ball flange 8, longitudinal adjustment hydraulic cylinder 9, transverse hydraulic cylinder 10, screw 11, limit device 2, the skid base 1 is placed at the lowest level, and the manifold bracket 4 passes The jacking hydraulic cylinder 5 is supported above the skid base 3; the manifold support frame 4 has a crossbeam group, and the crossbeam groups are fixed together by connecting rods. The crossbeam group is along the manifold support frame 4 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com