Dynamic length regulation device for refrigeration capillary tubes

A dynamic adjustment, capillary technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low efficiency, not necessarily finding the optimal length, and consuming a lot of manpower, material resources and time, and achieves high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

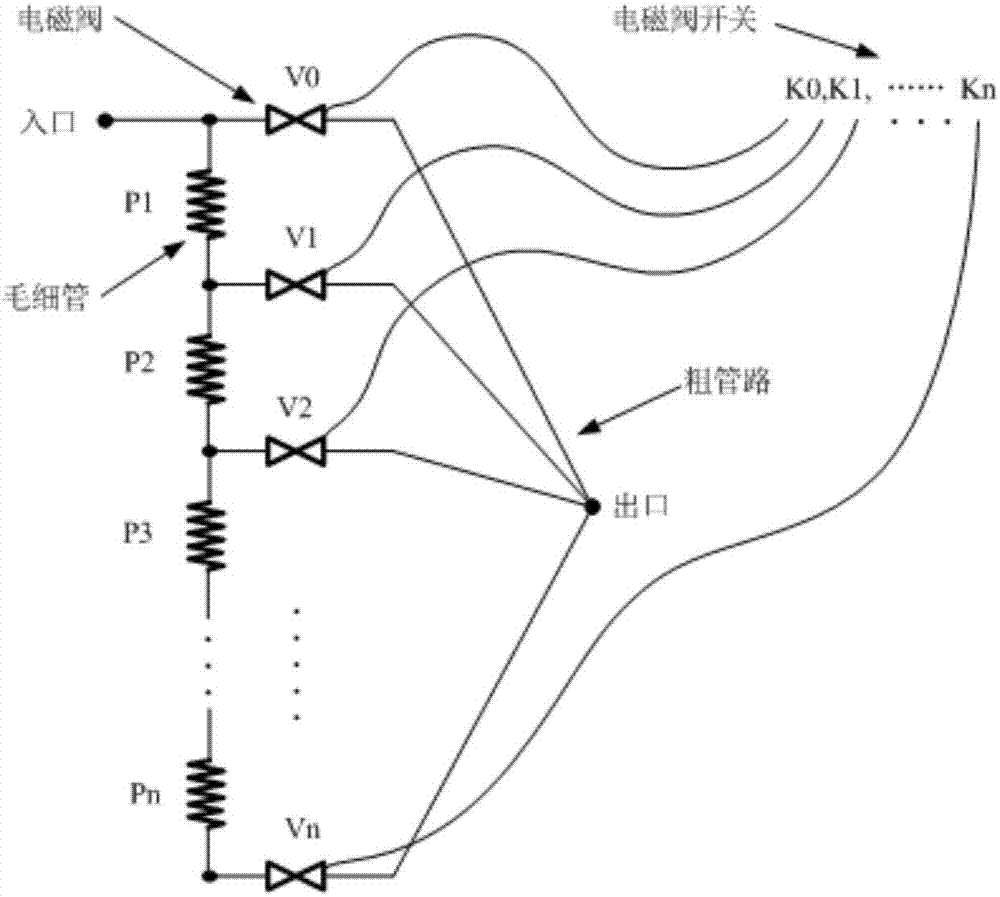

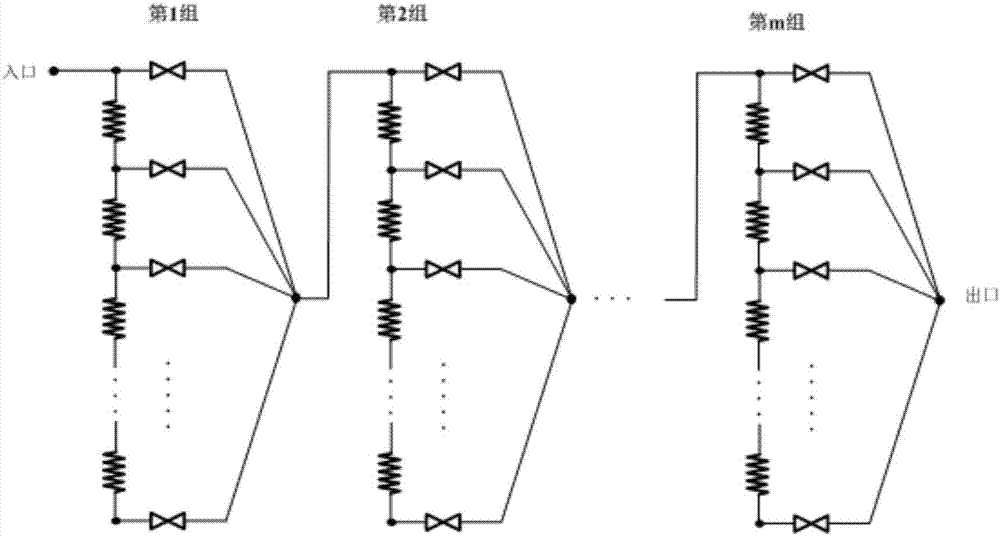

[0015] Such as figure 1 As shown, n capillaries of equal length are connected in series, and then connected with n+1 solenoid valves such as figure 1 connected as shown to form a single assembly. Such as figure 2 The overall application shown can be composed of several components connected in series to achieve more length combinations.

[0016] The capillary is a metal tube with an inner diameter in the range of 0.4 mm to 2 mm, which plays a throttling role. The length and inner diameter of each section of capillary in each module are the same, and the lengths of capillary in different modules are different. The thick pipe is a pipe with a larger inner diameter, which has a small flow resistance and does not have a throttling effect, but only serves as a pipe connection. The solenoid valve is normally closed, and the solenoid valve corresponds to the solenoid valve on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com