Lifting-hanging type bidirectional non-coupling presplitting blasting charge device and application method

A pre-split blasting and charging technology, which is applied in the open-air pre-split blasting project, in the field of a lift-type two-way uncoupled pre-split blasting charging device, can solve the problem of reducing the scope of the blasting crushing area, reducing the blasting vibration effect, and the complex charging process. and other problems, to achieve the effect of low production cost, reduction of excessive crushing, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

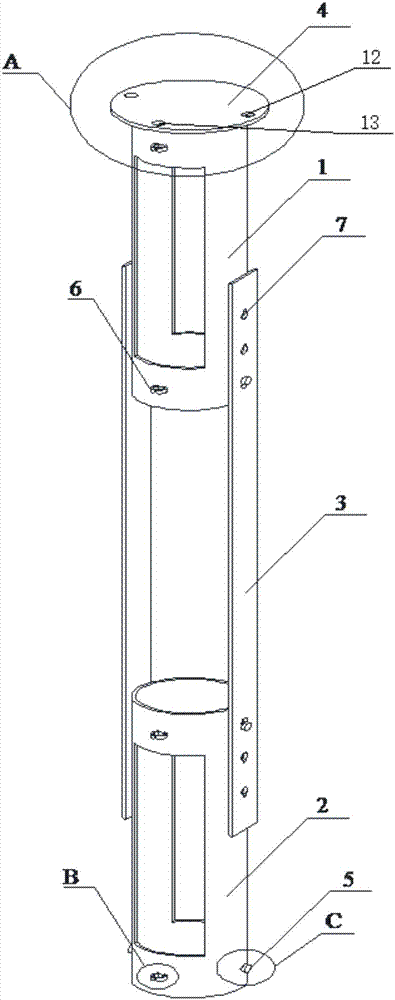

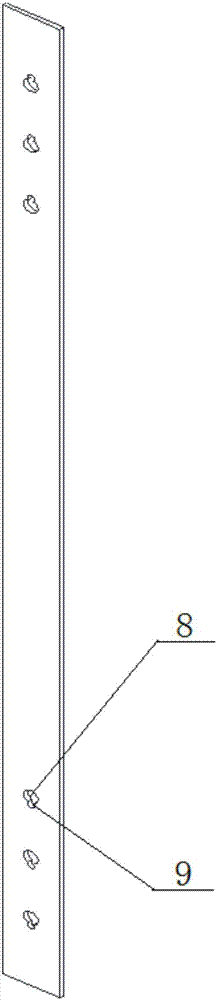

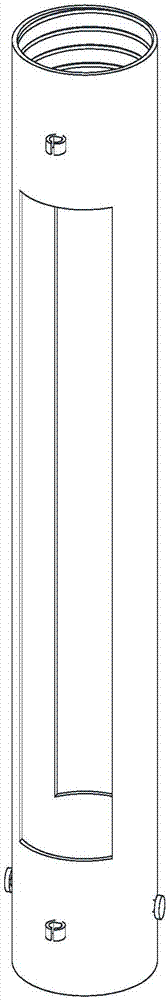

[0046] The blasting area is phyllite, the Platts firmness factor is 10, the pre-splitting hole depth is 15m, the pre-splitting hole diameter is 250mm, the filling length of the blast hole is 5.2m, and the hole spacing is 3m. Choose a density of 1.1g / cm 3 No. 2 rock emulsion explosive, the diameter of the explosive roll is 90mm, the length is 40mm, the diameter of the charge tug 2 is 92mm, the diameter of the charge top barrel 1 is 92mm, the length of the charge tug 2 is 30mm, and the interval length of the explosive roll is 1m , the length of the sling is 7m, and mark at 5.2m after removing the fixed length.

[0047] Concrete process implementation steps are as follows:

[0048] 1) According to the diameter of the selected explosive roll, select the charge tug 2 and the charge jack 1, and put the explosive roll into the charge tug 2 and the charge jack 1;

[0049] 2) According to the designed explosive roll interval length of 1m, select the tug connection element 3, pass the l...

Embodiment 2

[0054] The blasting area is mixed rock, the Platt's firmness factor is 10-14, the pre-splitting hole depth is 12m, the pre-splitting hole diameter is 200mm, the blasthole filling length is 3m, and the hole spacing is 2.4m. Choose a density of 1.1g / cm 3 No. 2 rock emulsion explosive, the diameter of the explosive roll is 80mm, the length is 40mm, the diameter of the charge tug 2 is 82mm, the diameter of the charge top barrel 1 is 82mm, the length of the charge tug 2 is 30mm, and the interval length of the explosive roll is 1.1 m, the length of the sling is 5m, and mark at 3m after removing the fixed length.

[0055] Concrete process implementation steps are as follows:

[0056] 1) According to the diameter of the selected explosive roll, select the charge tug 2 and the charge jack 1, and put the explosive roll into the charge tug 2 and the charge jack 1;

[0057] 2) According to the designed explosive roll interval length of 1.1m, select the tug connecting element 3, pass the...

Embodiment 3

[0062] The blasting area is mixed rock, the Platts firmness coefficient is 8-10, the pre-splitting hole depth is 10m, the pre-splitting hole diameter is 150mm, the blast hole filling length is 2m, and the hole spacing is 1.8m. Choose a density of 1.1g / cm 3 No. 2 rock emulsion explosive, the diameter of the explosive roll is 70mm, the length is 50mm, the diameter of the charge tug 2 is 72mm, the diameter of the charge top barrel 1 is 72mm, the length of the charge tug 2 is 35mm, and the interval length of the explosive roll is 0.5 m, the length of the sling is 4m, and a mark is made at 2m after the fixed length is removed. Specific process implementation

[0063] Concrete process implementation steps are as follows:

[0064] 1) According to the diameter of the selected explosive roll, select the charge tug 2 and the charge jack 1, and put the explosive roll into the charge tug 2 and the charge jack 1;

[0065] 2) According to the designed explosive roll interval length of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com