Tire-pavement three-dimensional force measuring device and measuring method thereof

A measuring device and three-way force technology, applied in the field of sensor measurement, can solve the problems that electromagnetic sensors are susceptible to electromagnetic interference, affect the accuracy of measurement, and have limited measurement data points, so as to achieve easy network array measurement, improve sensitivity and The effect of high precision and good anti-electromagnetic interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

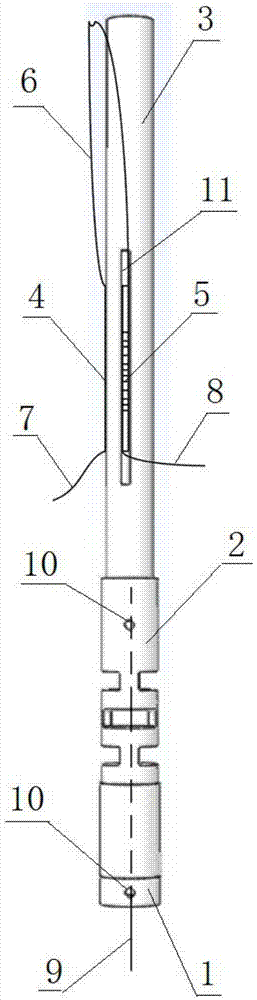

[0029] Such as image 3 As shown, the fiber grating sensor 17 in this embodiment includes a base 1, an inner rod 2 mounted on the base 1 through a threaded connection, and a straight rod 3 mounted on the inner rod 2 through a threaded connection, and the inner rod 2 is a hollow structure. The rod 2 and the straight rod 3 are elastic bodies with a cylindrical cantilever beam structure, and the rigidity of the hollow structure is much smaller than that of the cantilever beam structure, which reduces the mutual influence between the horizontal and vertical structures during measurement. In this embodiment, the straight rod 3 The length is 66mm and the diameter is 5mm. The hollow structure of the inner rod 2 is a three-section type with a total length of 12mm and 10mm at both ends. The material is 316L steel. The outer surface of the stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com