Brake disc noise detection test apparatus

A test device and brake pad technology, which is applied in measuring devices, vehicle testing, machine/structural parts testing, etc., can solve the problems of high cost, high cost of use, brake noise, etc., and achieve convenient use and short manufacturing cycle , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

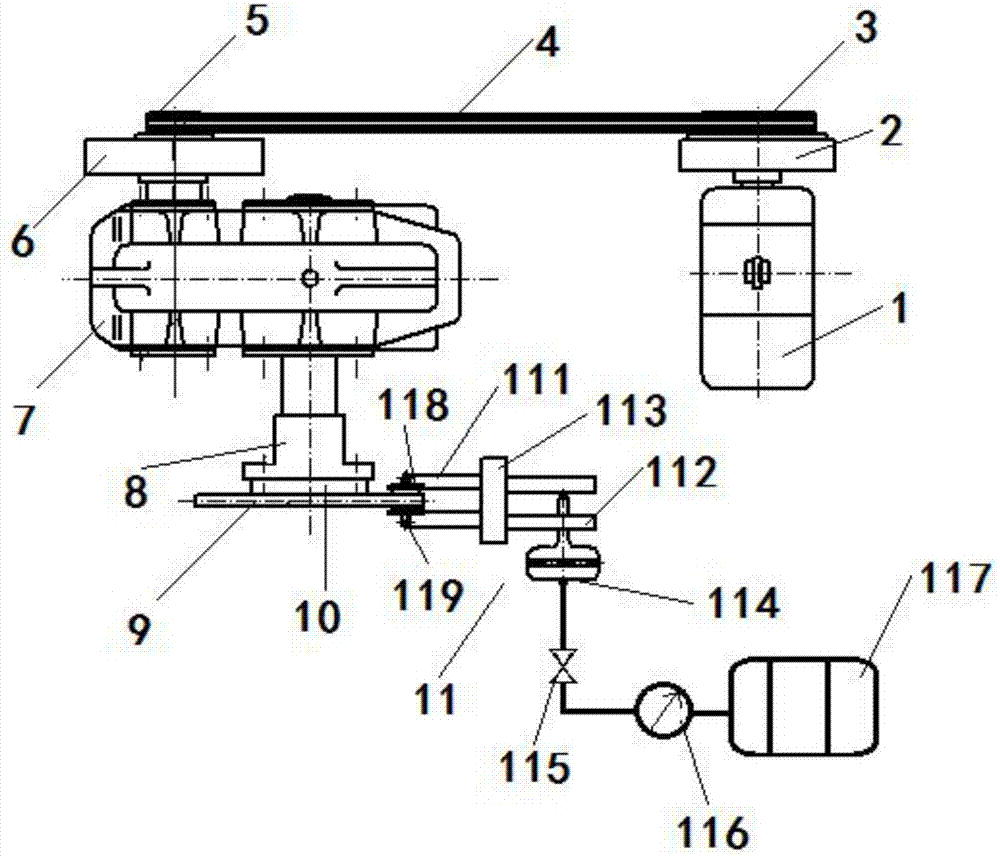

[0026] Such as figure 1 As shown, this embodiment provides a brake pad noise detection test device, including a motor 1, a reducer 7, a brake disc 9 and a brake device 11, the end of the output shaft of the motor 1 is provided with a motor pulley 3, and the end of the reducer 7 The end of the input shaft is provided with a reducer pulley 5, the motor pulley 3 and the reducer pulley 5 are connected by a V-belt 4 to realize the power transmission from the motor 1 to the reducer 7; The braking device 11 is used to brake the brake disc 9; at the same time, the output shaft of the motor 1 is provided with an inertia wheel I 2 for increasing the output torque, and the input shaft of the reducer 7 is provided with an inertia wheel II for increasing the input torque 6.

[0027] In this embodiment, the braking device 11 includes a clamp, which is composed of a first clamping piece 111 and a second clamping piece 112 arranged in parallel and having the same size. The first clamping pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com