Triaxial-test sample preparation device and sample preparation method

A technology of triaxial test and valve mold, which is applied in the direction of measuring device, test sample preparation, sampling, etc., can solve the problems of sample layering, difficult control of sample preparation quality, and inconsistent compaction degree at both ends of the sample, etc. Achieve the effect of avoiding disintegration and damage and improving the quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

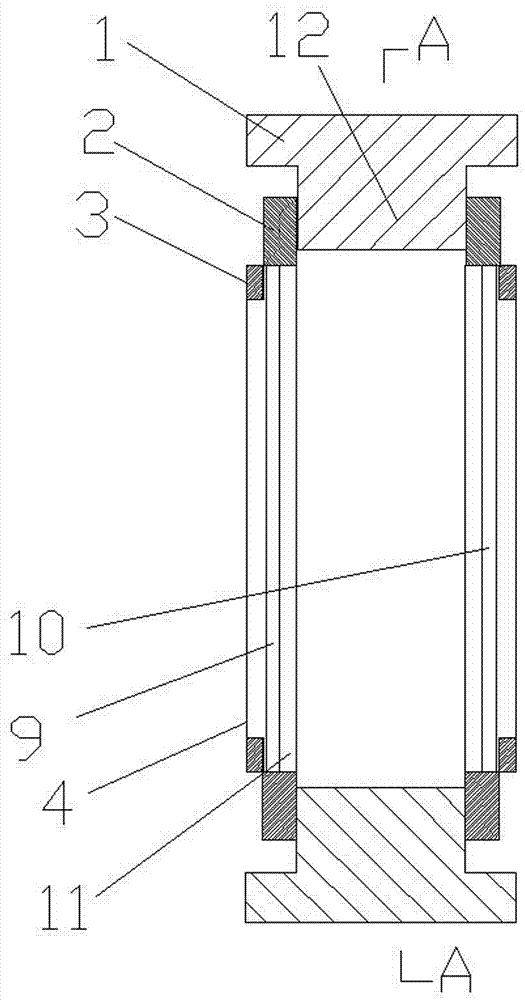

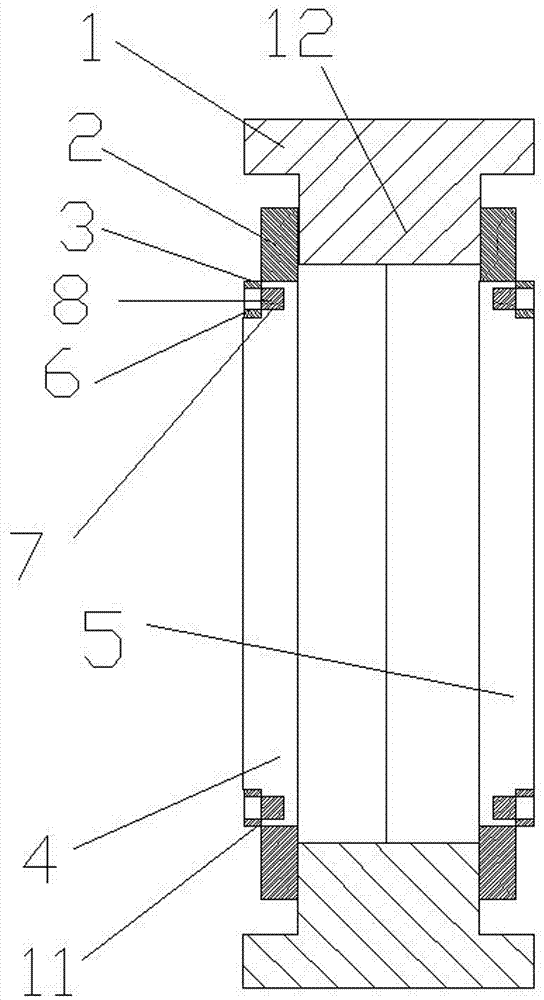

[0027] A triaxial test sample preparation device, including buckle mold and demoulding, is characterized in that:

[0028] The buckle mold includes a valve mold assembly, an upper fastening assembly and a lower fastening assembly.

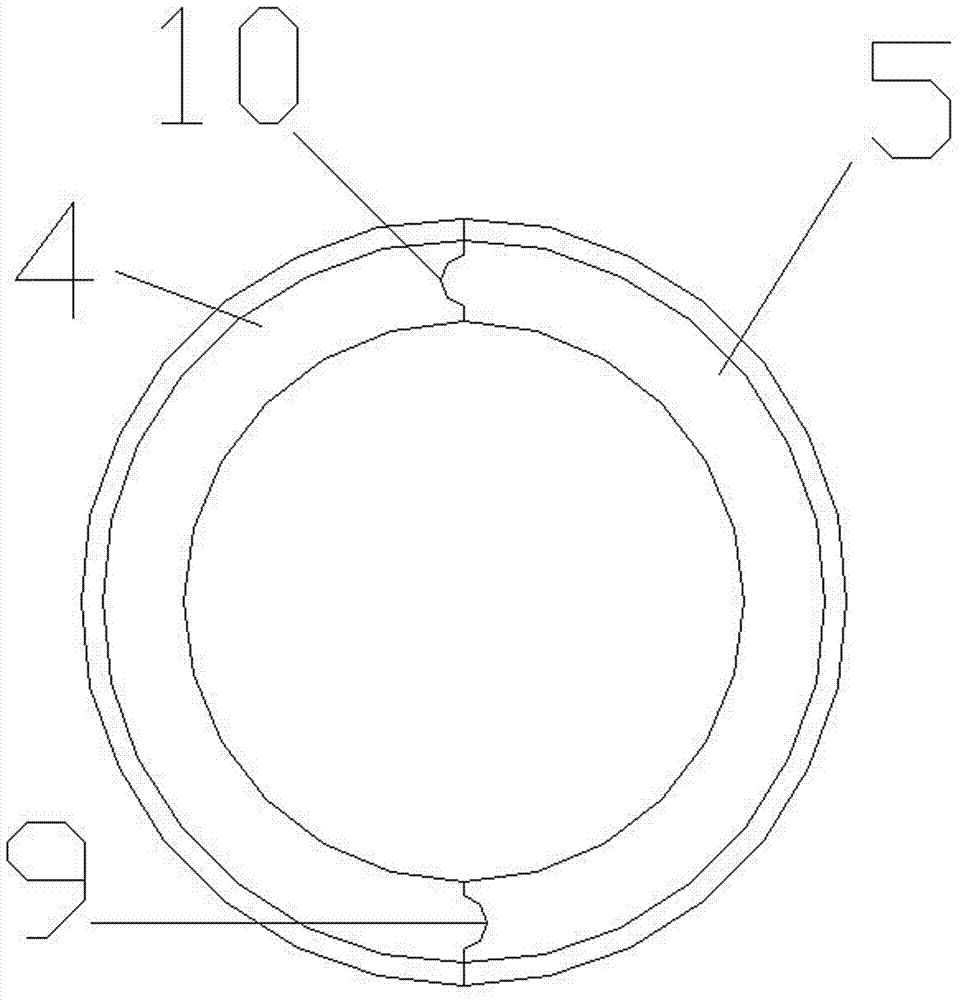

[0029] The valve mold assembly includes a left valve mold 4 and a right valve mold 5, the cross section of the left valve mold 4 is a semi-circular structure, and the upper end surface and the lower end surface of the left valve mold 4 are respectively provided with a necking valve mold 11, and the necking valve mold The outer diameter of 11 is smaller than that of the left valve mold 4. On the docking plane of the left valve mold 4, a linear flange 9 is arranged axially on one side, and a linear groove 10 is arranged axially on the other side.

[0030] The structure of the right lobe mold 5 is exactly the same as that of the left lobe mold 4, and the right lobe mold 5 and the left lobe mold 4 are fastened and connected.

[0031] The upper fasteni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com