Electric vehicle battery thermal management system employing porous material

A battery thermal management and porous material technology, applied in the field of electric vehicle battery thermal management system, can solve problems such as thermal runaway of battery boxes, safety accidents, etc., and achieve the effects of improving reliability, improving mass density, and alleviating huge momentum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

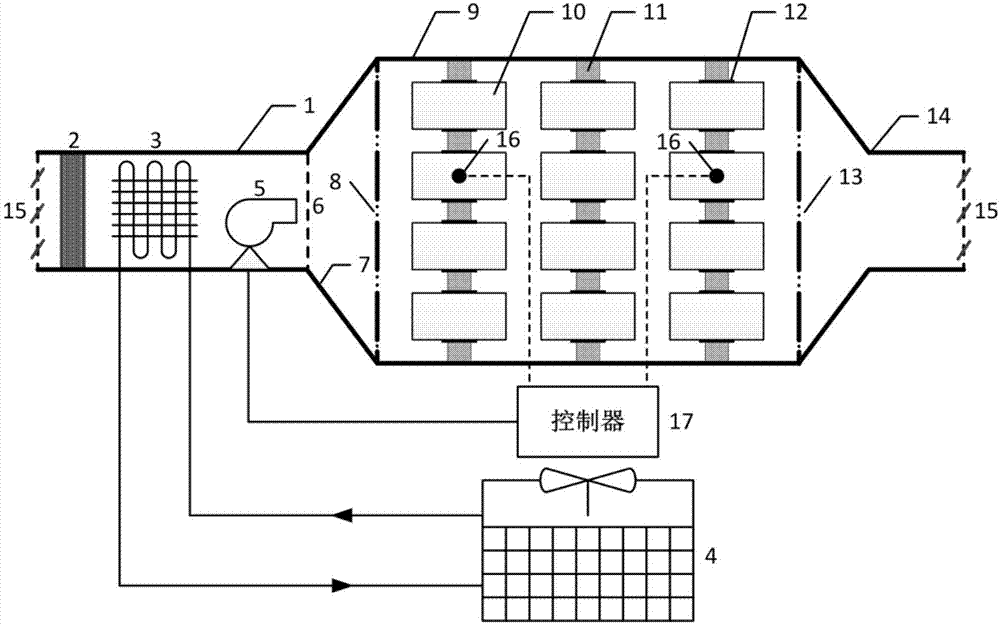

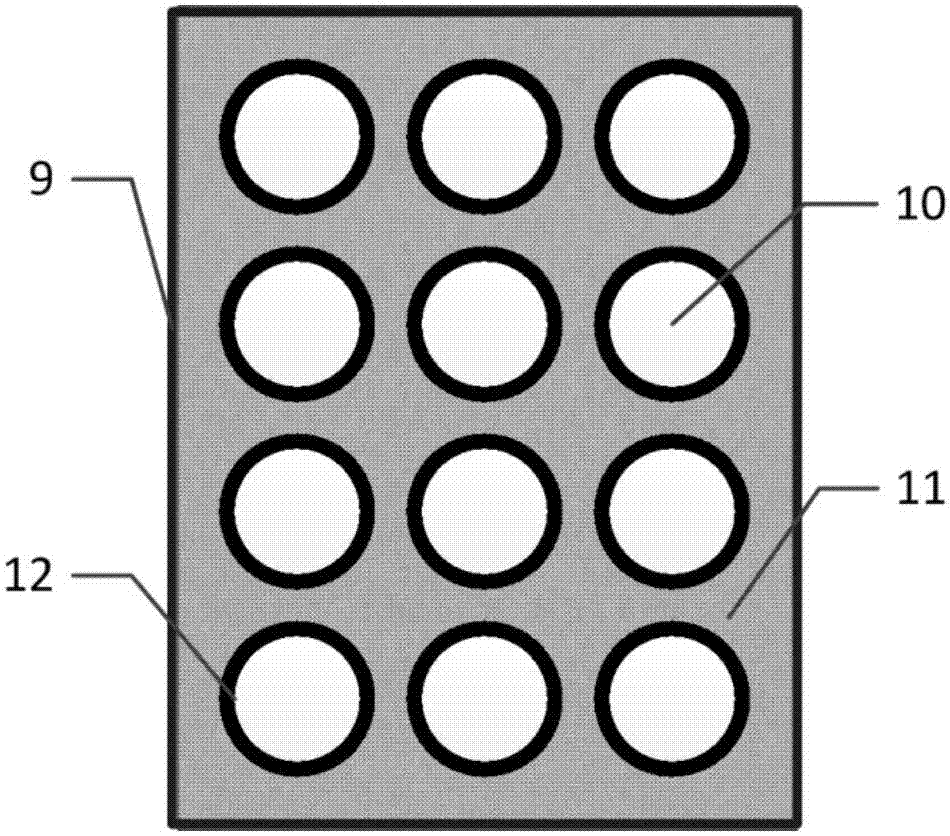

[0031] like figure 1 and figure 2 As shown, the present invention uses a porous material electric vehicle battery thermal management system, which includes two main parts, namely, the power battery pack battery box and the air handling system.

[0032] The air handling system is a heat pump refrigeration system. The air handling system includes an indoor unit part 1 and an outdoor unit part 4. The two parts are connected by pipes. The cooled / heated air passes through the air outlet 6 of the indoor unit through the air supply pipe 7. The air inlet 8 of the battery box is sent into the inside of the battery box 9, the battery unit 10 is cooled / heated, and then flows out of the battery box 9 through the air outlet 13 of the battery box, and then returns to the indoor unit part 1 through the air return pipe 14.

[0033] The air handling system fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com