360° detection sensor and detection method based on area array ccd/cmos

A CMOS sensor and detection sensor technology, applied in the field of sensors, can solve the problems that cannot be eliminated, increase the complexity of the system, restrict the service life, etc., and achieve the effect of strong anti-interference ability in the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

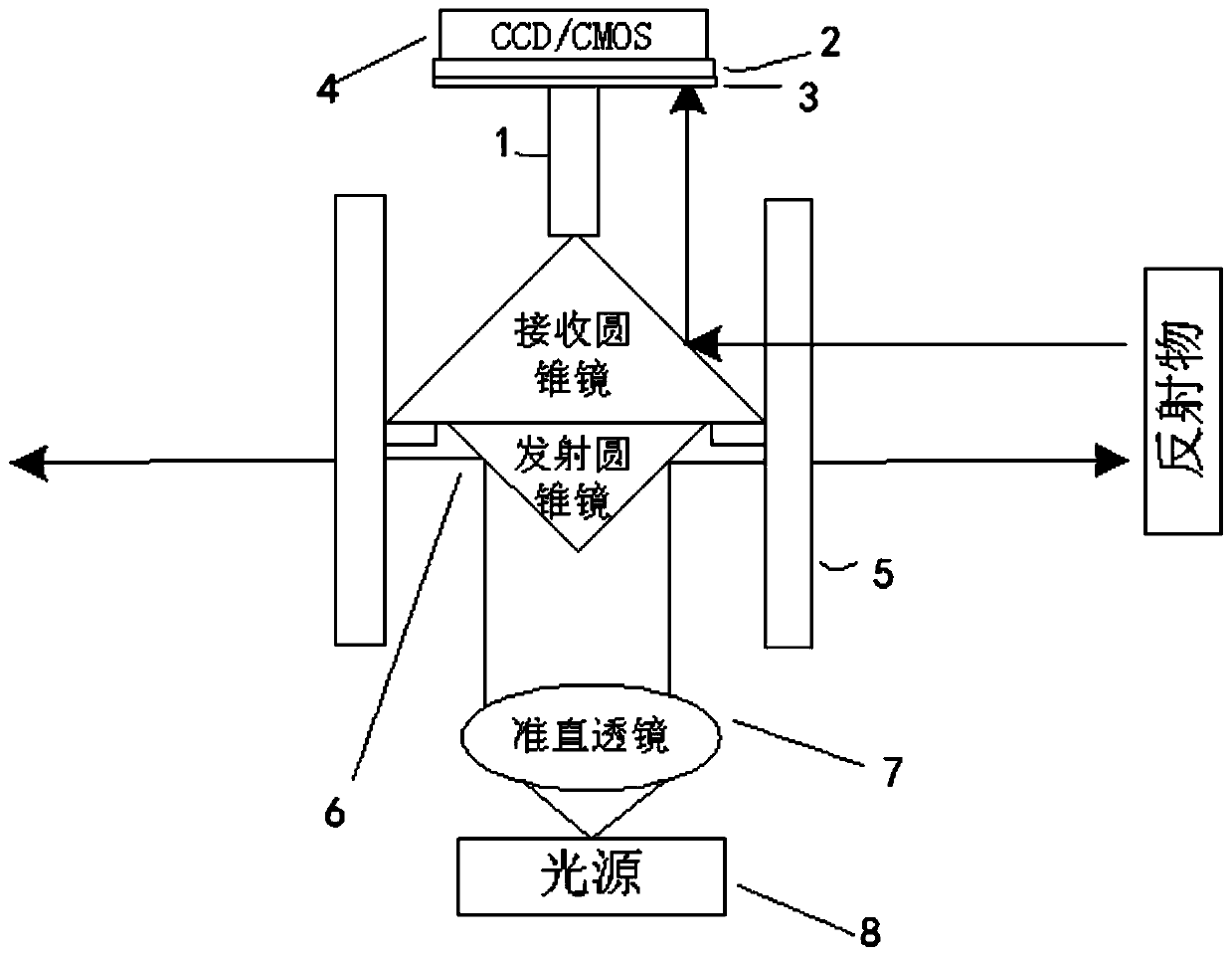

[0024] Such as figure 1 Shown is a specific embodiment of the application. This embodiment comprises area array CCD / CMOS sensor 4, conical mirror 6, and conical mirror 6 comprises emitting conical mirror, receiving conical mirror, light-shielding cylinder 1, light source 8, collimating lens 7, narrow-band optical filter 2, cylindrical window 5 (on the one hand, this component plays a supporting role as a structural component, and on the other hand, it is used as an optical component to transmit light), a circular aperture stop 3, an image processor unit module, a light source driving module, a signal output unit, a display unit module, etc. The area array CCD / CMOS sensor 4, the light source driving module, the signal output unit, and the display unit module are all connected to the image processing unit module, and the light source is connected to the light source driving module. The emitting light source shoots to the conical tip of the emitting conical mirror, the circular ...

Embodiment 2

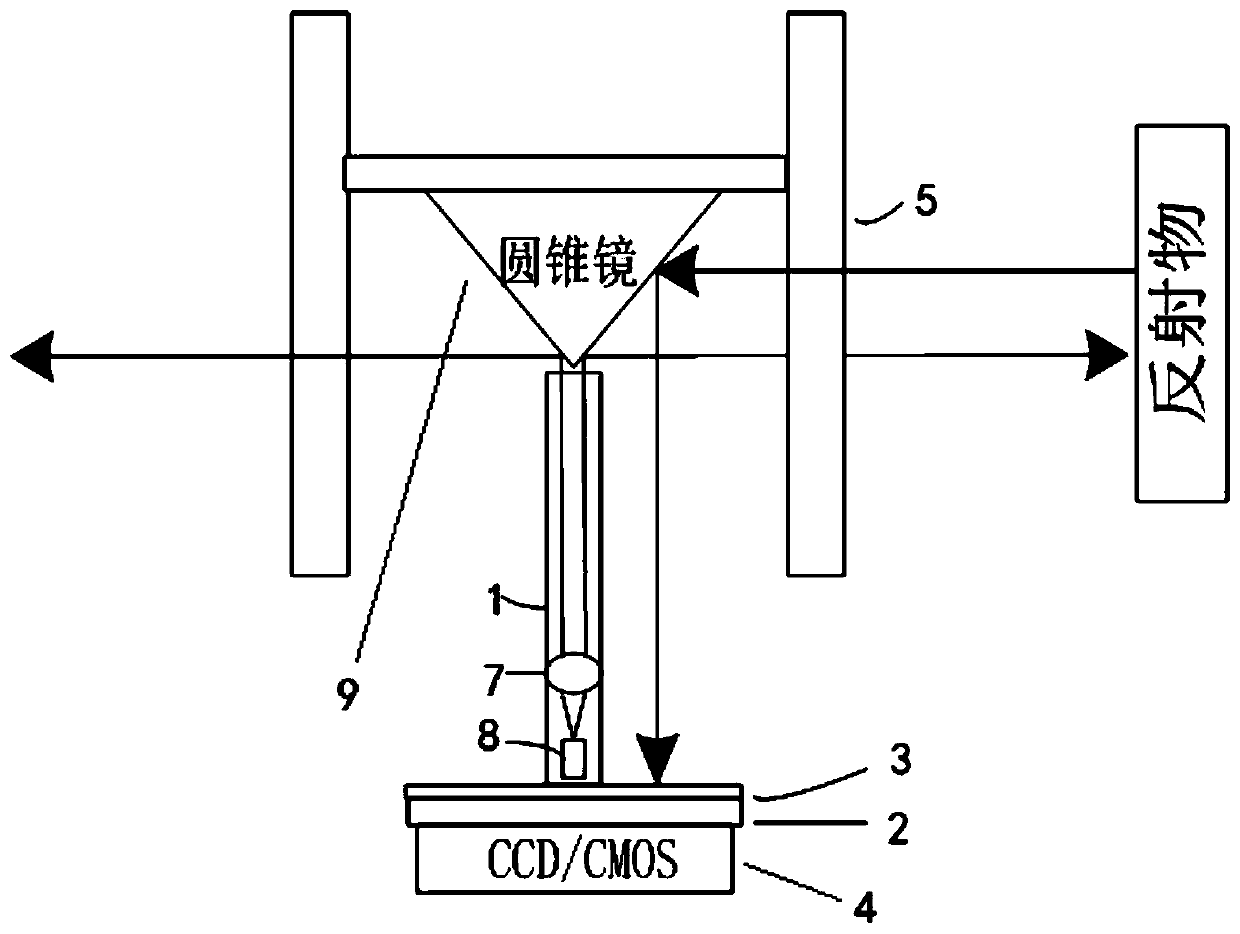

[0026] Such as figure 2 As shown, the difference from Embodiment 1 is that the conical mirror 9 is a single conical mirror, the light source 8 is arranged on one side of the conical mirror 6, the conical mirror 6 is arranged in the cylindrical window 5, and the shading tube 1 is covered by the light source 8, Around the collimating lens 7 and on one side of the light-shielding tube 1 are sequentially arranged a circular aperture stop 3 , a filter 2 , and an area array CCD / CMOS sensor 4 , and the others are the same.

[0027] It should be noted that, in the above-mentioned embodiments 1 and 2, the emitting light source can be a laser light source or LED light source of any wavelength band, and can be red light, infrared light, green light, blue light, etc.; the emitting light source is collimated emitted light , is an approximately parallel beam. The emission of light to obtain a fan or circumference is obtained through a conical mirror. In embodiment 1, the conical half-ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com