Bearing intelligent temperature control heater

An intelligent temperature control and heater technology, applied in induction heating, induction heating devices, metal processing and other directions, can solve the problems of difficult access to bearings, complex structure, waste of resources, etc., to achieve low cost, accurate and controllable temperature, The effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

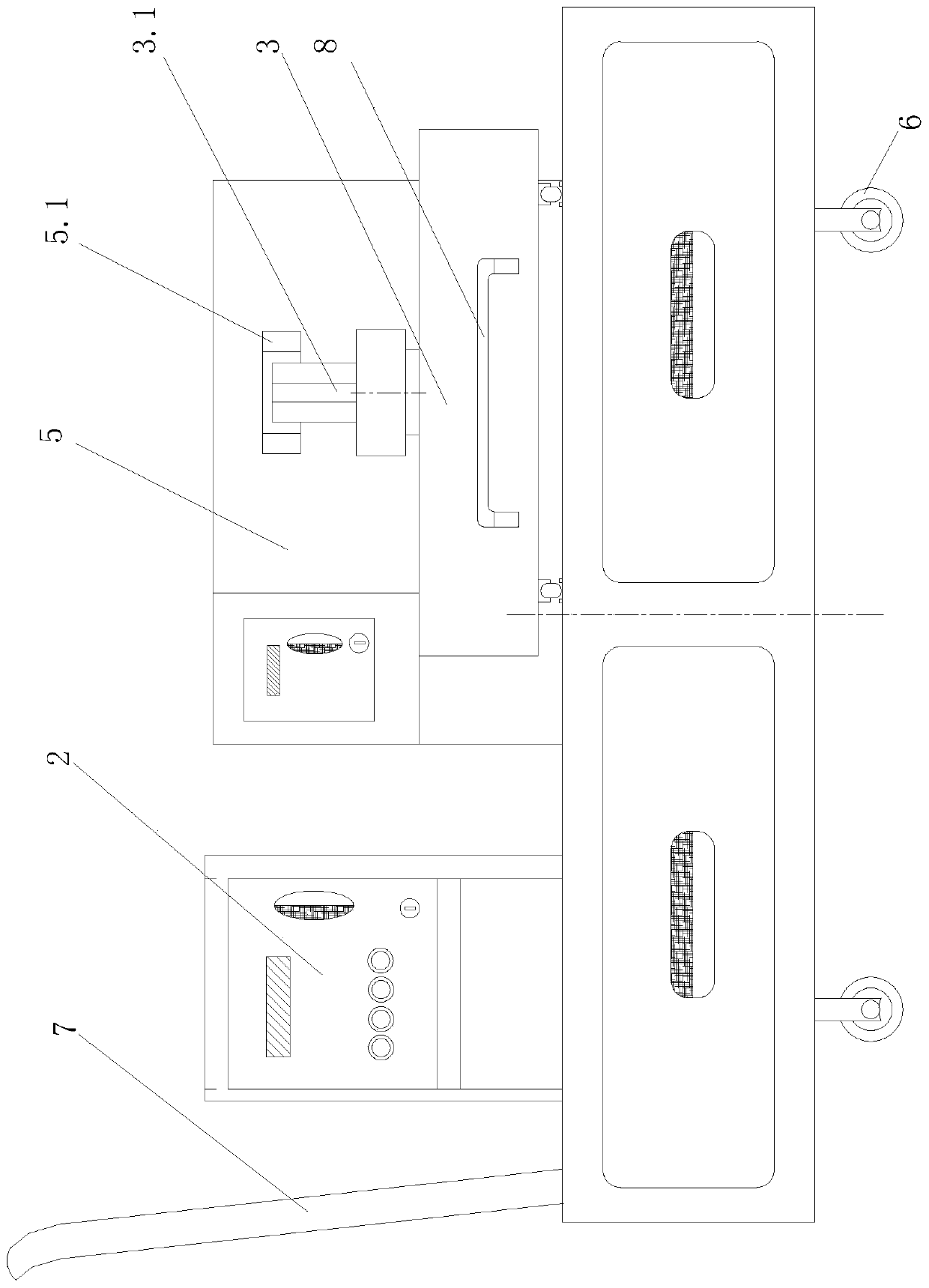

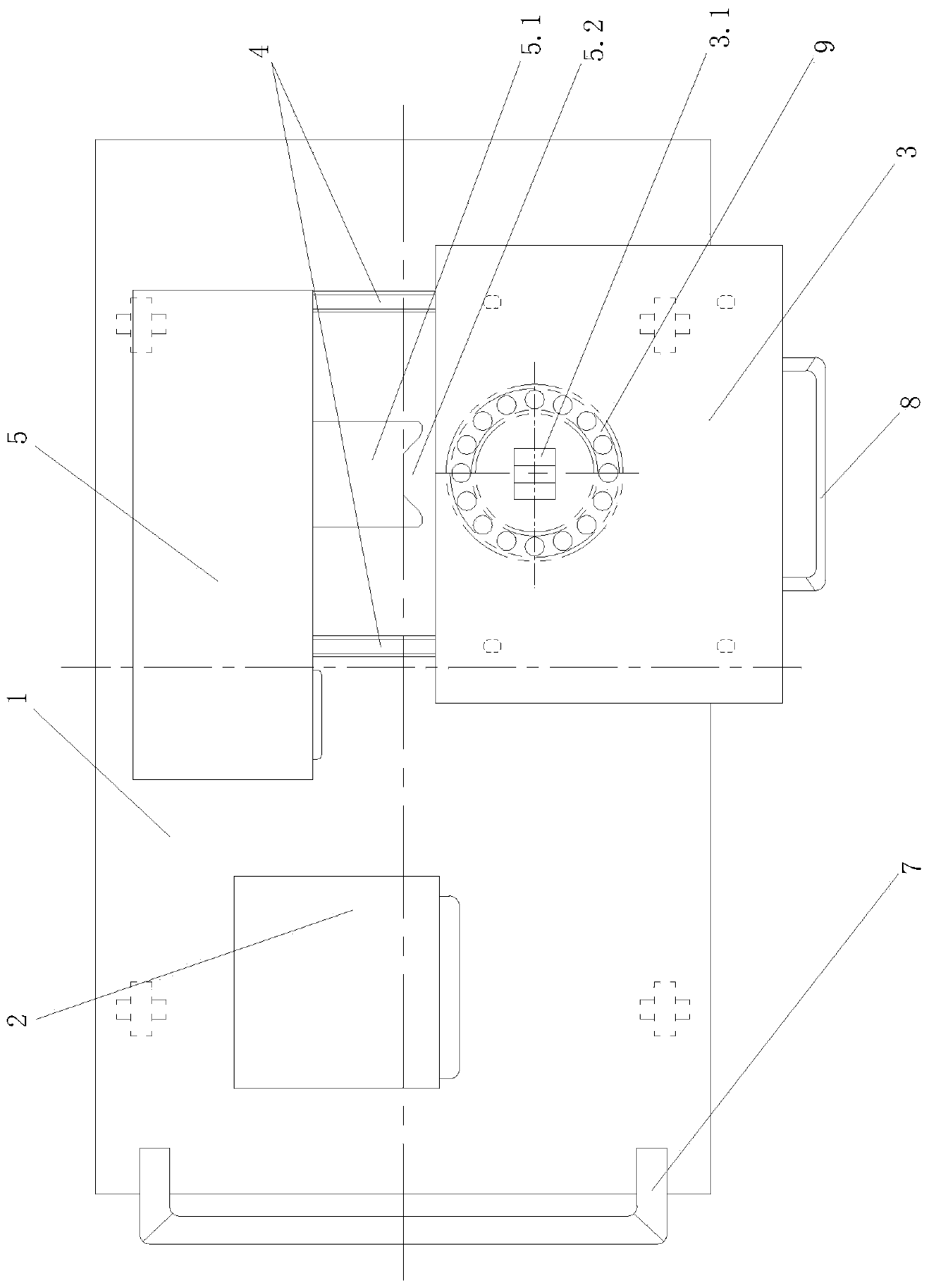

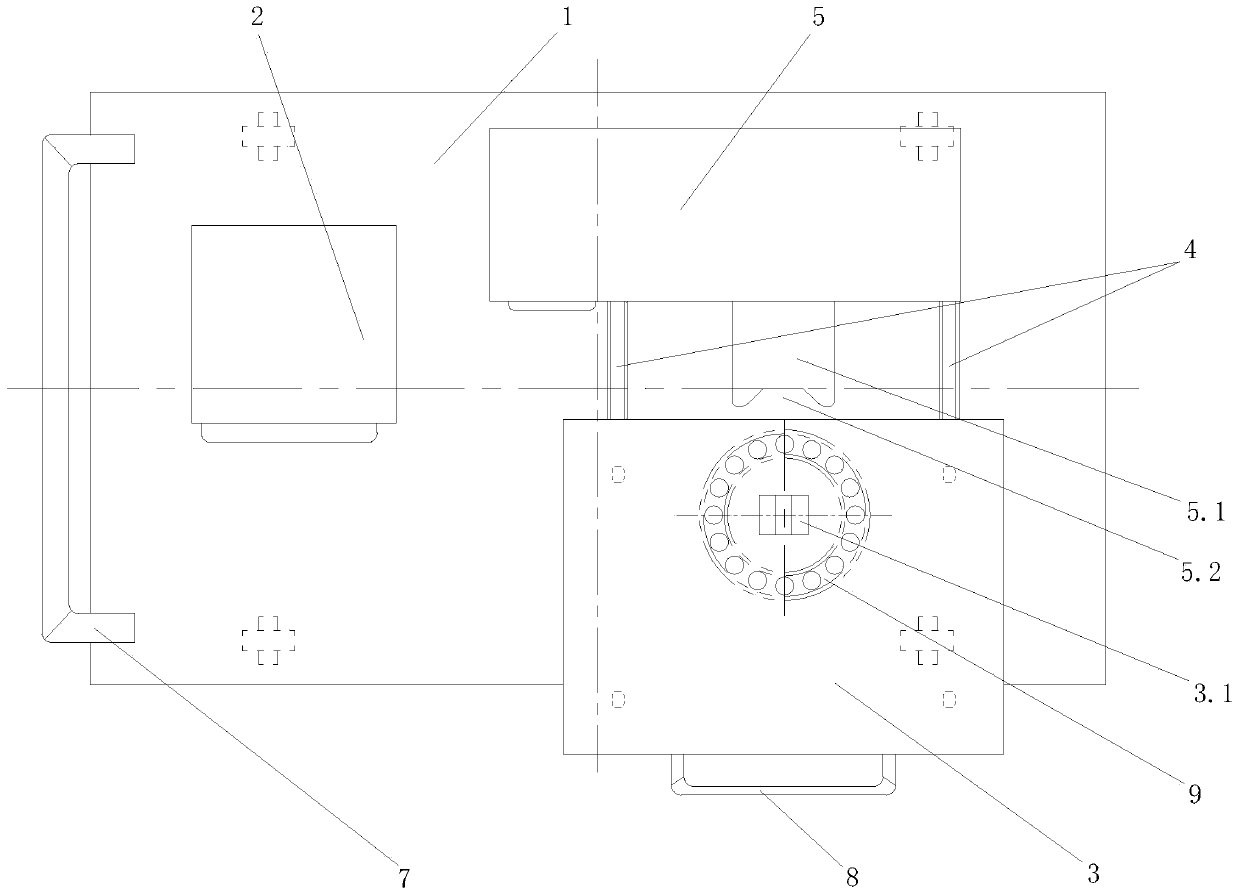

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a platform 1, a control center 2, a bearing shelving trolley 3, a track 4 and a bearing electromagnetic heating device 5. The control center 2 is arranged on the left side of the platform 1, the bearing electromagnetic heating device 5 is arranged at the rear part of the right side of the platform 1, and the control center 2 and the bearing electromagnetic heating device 5 are electrically connected. Bearing shelving dolly 3 is located at the front portion of the right side of platform 1. The bearing electromagnetic heating device 5 is provided with a bump 5.1 for electromagnetic heating, and the bump 5.1 has two pieces, one of which is located above the other bump 5.1; the front part of the bump 5.1 is provided with a trapezoidal The distance between the notch 5.2, the lower surface of the upper projection 5.1 and the upper surface of the lower projection 5.1 is greater than the axial thickness of ...

Embodiment 2

[0022] The difference between the second embodiment and the first embodiment is that the platform push handle 7 in this embodiment is a T-shaped connecting rod, the lower end of which is connected to the platform 1, and the upper end is a handshake push handle, which is higher than the control handle. The upper end of both the center 2 and the bearing electromagnetic heating device 5 is higher, and the upper end of the handshake push handle is located on the left side of the platform 1 . In addition, the trolley pusher handle 8 provided at the front end of the bearing shelving trolley 3 is also horizontally T-shaped, consisting of a horizontal bar parallel to the front end of the bearing shelving trolley 3 and a horizontal vertical bar perpendicular to the front end of the bearing shelving trolley 3, T The free end of the shaped vertical bar links to each other with the front end of bearing shelving dolly 3.

Embodiment 3

[0024] The difference between the third embodiment and the first embodiment is that, in the third embodiment, the platform pushing handle 7 includes a drawstring storage column fixed on the left side of the platform 1 and a drawstring fixedly connected to the drawstring storage column at one end. When the bearing is heated, the stay rope is wound on the stay rope storage post. When the platform 1 is to be moved, untie the winding of the stay rope to the stay rope storage post, and then pull the stay rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com