High-speed feeding device of compounding machine

A technology of feeding device and composite machine, applied in the direction of feed, food science, application, etc., to achieve the effect of prolonging the service life, increasing the burden of the motor, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

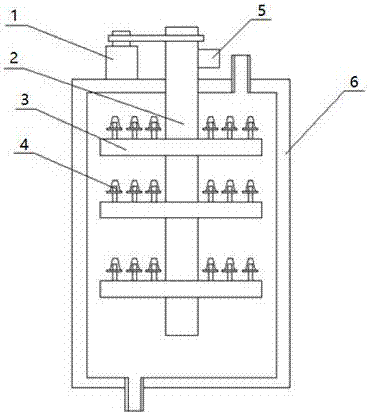

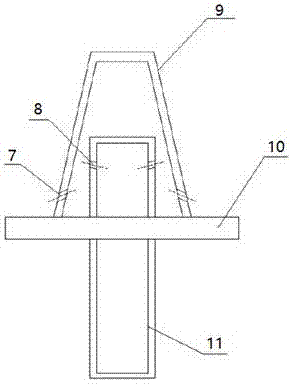

[0014] like Figure 1-2 As shown, a high-speed feeding device of a compound machine includes a stirring tank 6, a stirring shaft 2 arranged inside the stirring tank 6, a material inlet is provided on the side of the top of the stirring tank 6, and a material outlet is provided on the side of the bottom of the mixing tank 6, Stirring shaft 2 is placed outside the axis of stirring tank 6, and the top of stirring shaft 2 is placed outside stirring tank 6. Stirring shaft 2 outside stirring tank 6 is connected with motor 1 and air pump 5. Stirring rods 3 are evenly distributed on the surface of stirring shaft 2. Stirring The air blowing pipe 4 is evenly distributed on the rod 3, the stirring shaft 2 and the stirring rod 3 are hollow structures, the upper end of the stirring rod 3 is provided with evenly distributed air outlets, the air outlets are connected with the air blowing pipe 4 correspondingly, and the distance between the air outlets is 3 1 / 4 of the total length, the air bl...

Embodiment 2

[0016] like figure 1 , 2 As shown, when the high-speed feeding device of a compound machine of the present invention is actually used: a material outlet is provided on the side of the bottom of the closed mixing tank 6, and the material is poured from the material inlet provided on the side of the top of the mixing tank 6, and the motor 1 Drive the stirring shaft 2 to rotate and drive the stirring rod 3 to stir the materials. At the same time, the air pump 5 starts, and the gas is blown out from the blowing pipe 4 to prevent the material from adhering to the surface of the stirring rod 3. The surface of the stirring rod 3 and the stirring shaft 2 is coated with anti-rust The coating can effectively avoid the impact of corrosion on the quality of the material, and the anti-rust coating also has the function of preventing the material from adhering to the surface of the stirring rod 3 and the stirring shaft 2. When the stirring is completed, open the bottom side of the mixing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com