Flowmeter cleaning and flowmeter adapter automatic installing line

An automatic installation and adapter technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve unfavorable verification efficiency, cumbersome disassembly and assembly, and high cost of flow meter specifications and verification pipe specifications Solve problems such as manpower and time, and achieve the effect of automatic installation, labor saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

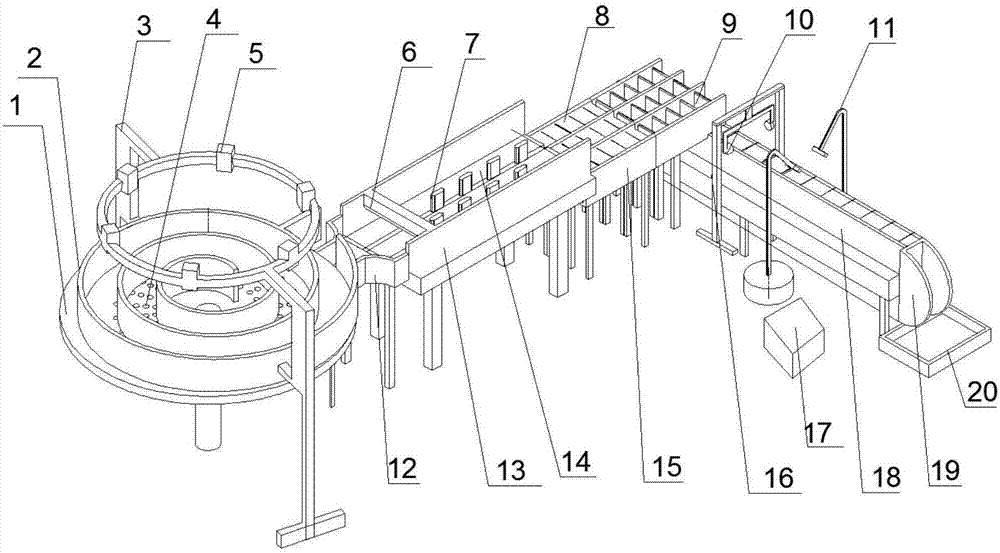

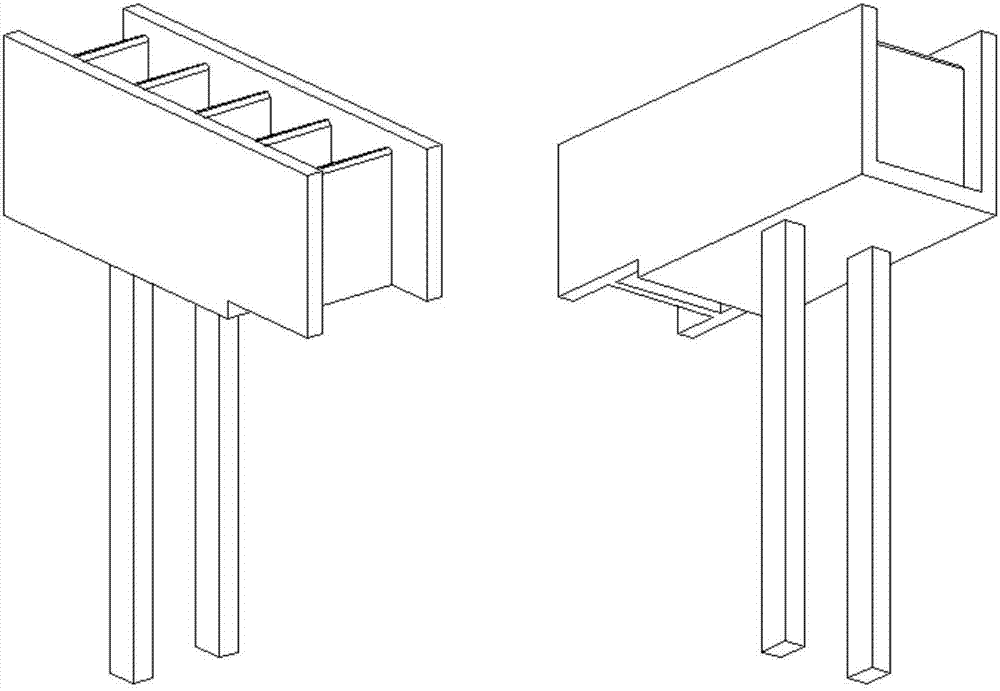

[0035] see figure 1 As shown, it is the flow meter cleaning and its adapter automatic installation line according to the present invention, including the rotating chassis 1), the spiral guide plate 2, the water gun bracket 3, the diversion hole 4, the high-pressure water gun 5, and the height limit plate 6 , horizontal limit plate 7, movable baffle 8, fixed baffle 9, camera 10, manipulator 11, transition slide 12, primary posture correction area 13, conveyor belt 14, secondary posture correction area 15, camera bracket 16, transfer Shelves 17, assembly transport lines 18, transport line diverters 19, sorting tables 20.

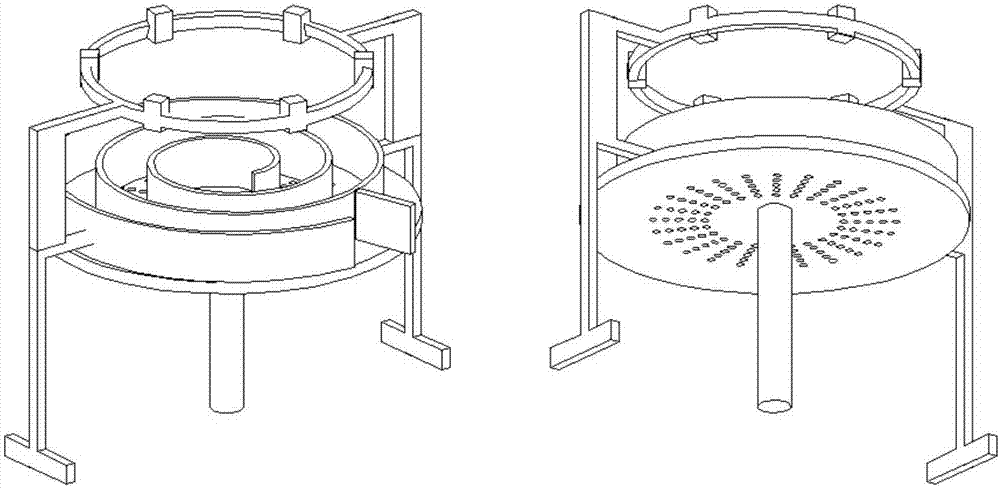

[0036] Such as figure 2 As shown, a plurality of diversion holes 4 are arranged on the rotating chassis 1, and the plurality of diversion holes 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com