Cabin decorative plate for automobile

A technology for decorative panels and car cabins, applied in lamination devices, vehicle parts, transportation and packaging, etc., can solve problems such as single function, inability to truly degrade formaldehyde, and inability to meet needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

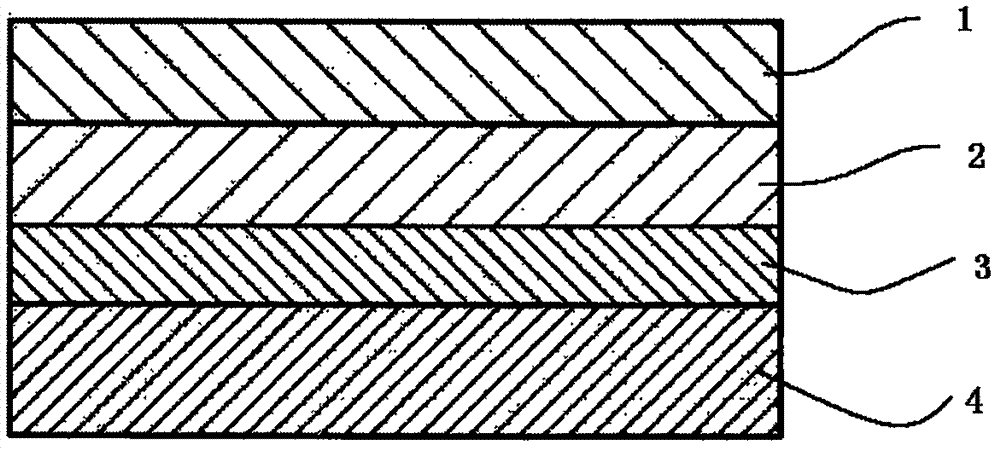

[0017] see figure 1 , figure 1 It is a schematic structural view of the vehicle cabin trim panel of the present invention. It includes at least four layers, including a flame-retardant fabric layer 1, a sterilizing filter purification layer 2, a hot-melt adhesive film 3 and a non-woven fabric layer 4, wherein the filter purification layer 2 is located between the flame-retardant fabric layer 1 and the hot-melt adhesive film 3 In between, the non-woven fabric layer 4 is used as a substrate and is located at the bottom of the hot melt adhesive film 3 . The decoration material is a roll material, which is convenient for storage, transportation and processing.

[0018] The core of the present invention lies in the production and manufacture of the bactericidal filtration purification layer 2, which is made of polypropylene (PP) resin, polyethylene (PE) resin and inorganic nano-sterilization purification solution through processing, and its specific method is Parts by weight: 50...

Embodiment 2

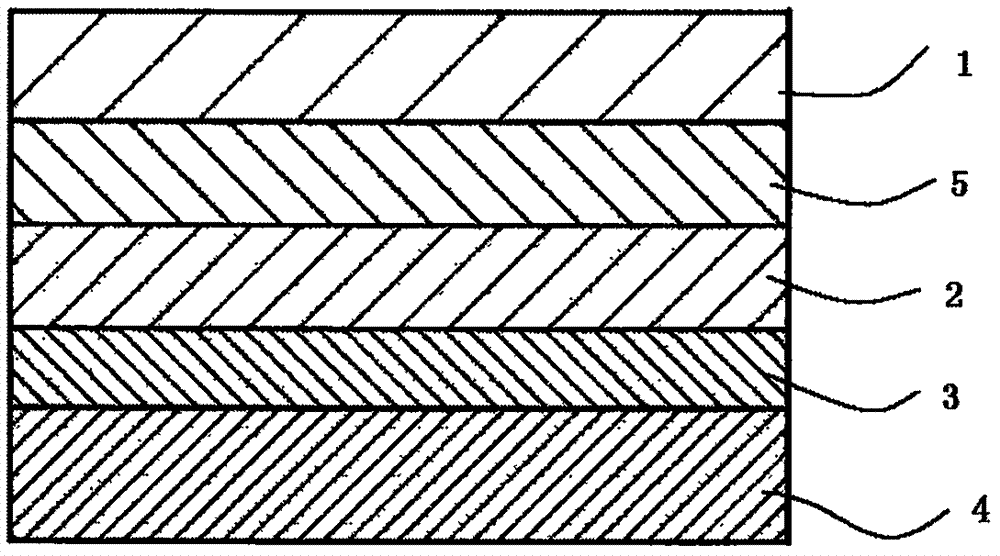

[0022] see figure 2 , figure 2 It is a schematic structural view of the vehicle cabin trim panel of the present invention. It includes at least five layers, including a flame-retardant fabric layer 1, a sterilizing filter purification layer 2, a hot-melt adhesive film 3 and a non-woven fabric layer 4, and also includes a breathable and waterproof layer 5, a flame-retardant fabric layer 1 and a breathable and waterproof layer 5. The filter and purification layer 2 is located between the breathable waterproof layer 5 and the hot-melt adhesive film 3, and the non-woven fabric layer 4 is used as a substrate at the bottom of the hot-melt adhesive film 3. At the same time, the decorative material is a roll material, which is convenient for storage, transportation and processing.

[0023] Same as Example 1, the sterilizing filtration purification layer 2 is processed by polypropylene (PP) resin, polyethylene (PE) resin and inorganic nano-sterilization purification solution, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com