Underpinning structure and construction method for replacing unqualified shearing wall concrete

A shear wall and concrete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of common people's disputes, easy to leave traces, etc., and achieve the effect of saving construction period and project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

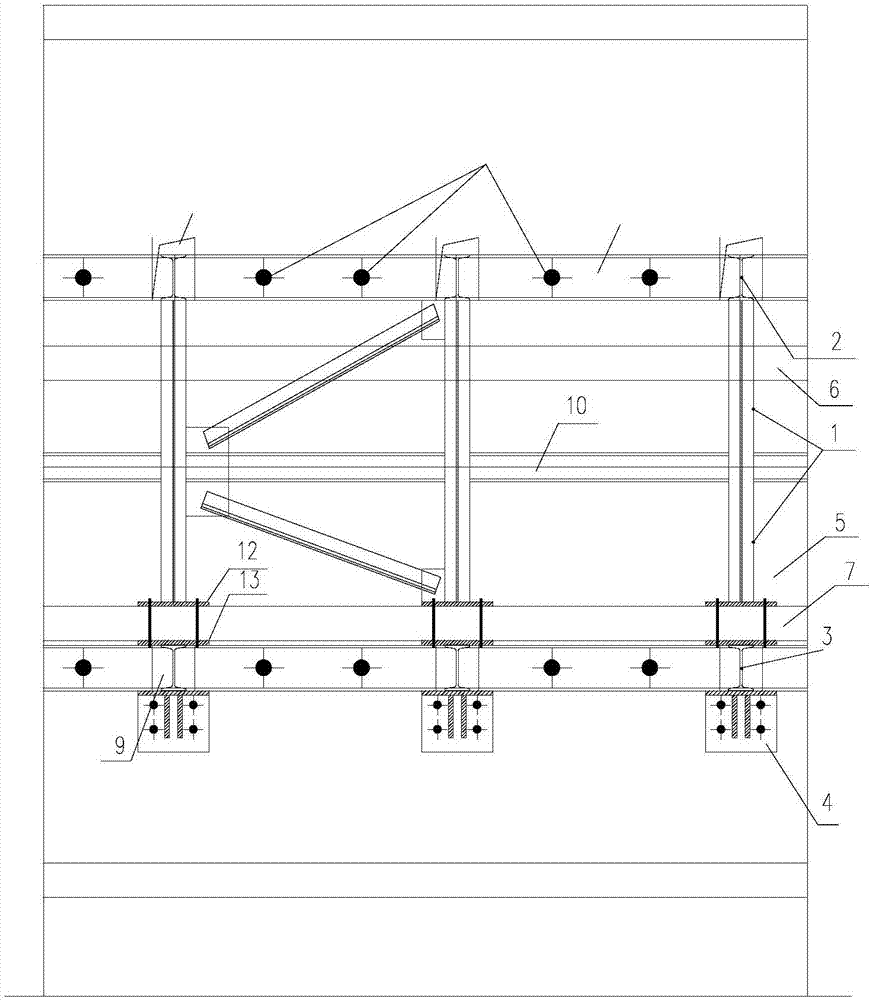

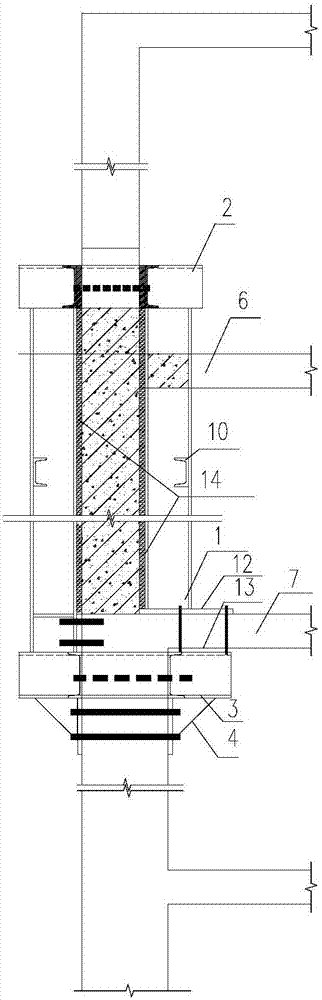

[0030] Example: such as Figure 1 to Figure 4-2 As shown, an underpinning structure for substituting unqualified shear wall concrete includes several columns 1, upper beams 2, lower beams 3, and supports 4; 5, the top of the column 1 passes through the upper floor 6 to connect with the upper beam 2, and the lower part is supported by the lower beam 3 below the lower floor 7; the upper beam 2 is cut out through the shear wall on the upper floor The hole 8 of the lower beam passes through the hole 9 cut out in the shear wall of the next floor; the support 4 is installed under the lower beam 3 to hold the lower beam 3; the whole underpinning structure is used to support the replacement floor above The weight of all structures.

[0031] An upper beam 2 , a lower beam 3 and a support 4 are respectively arranged above and below the plurality of upright columns 1 .

[0032] The middle part of the column 1 on the same side of the shear wall that needs to replace the concrete, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com