Reusable slope prefabricated immersed tube joint platform device and tube joint prefabricating method

A technology of platform devices and pipe joints, applied in water conservancy projects, reinforced molding, artificial islands, etc., can solve the problems of hard to find the location of the dry dock, the impact of the surrounding environment, and the large amount of excavation of the foundation pit, so as to reduce the dredging of the channel Quantity, saving project cost and construction period, the effect of small site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

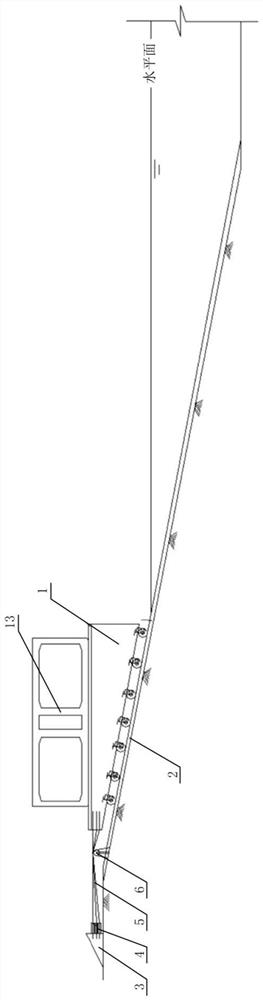

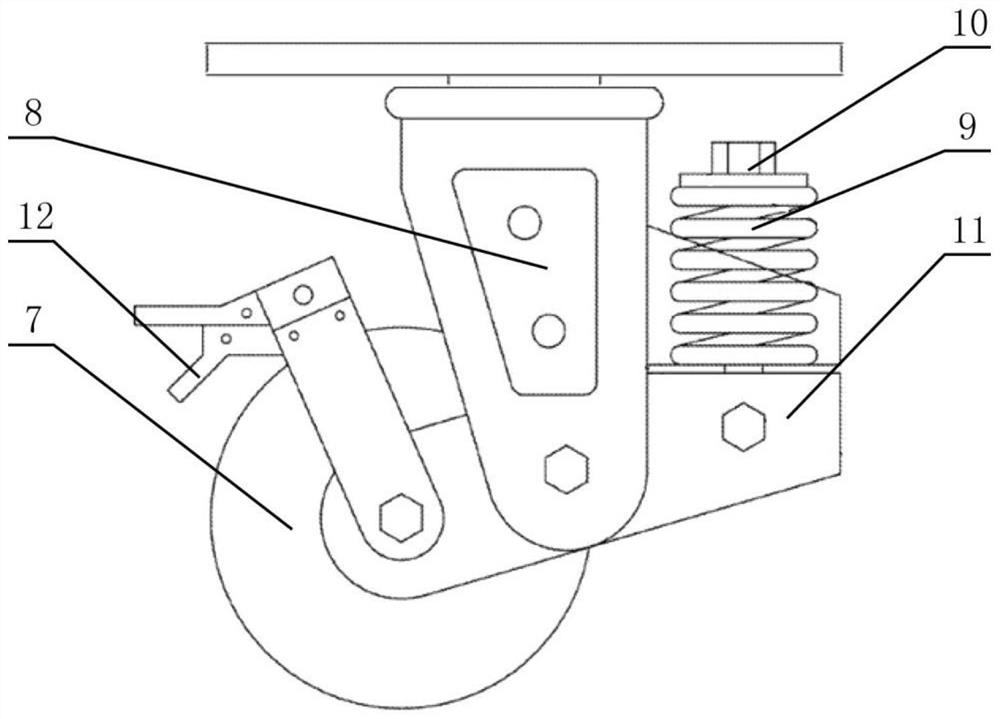

[0027] Embodiments of the present invention provide a reusable slope prefabricated immersed pipe section platform device, such as Figure 1-3 As shown, it includes a traction mechanism, a pipe joint prefabricated platform 1, a pulley mechanism and a slide rail 2. The slide rail 2 is laid along the slope of the embankment, and a part is located below the water level. The pipe section prefabrication platform 1 is used as the production platform of the pipe section 13 of the immersed tunnel, and its size depends on the slope of the slide rail 2 and the size of the pipe section 13 of the immersed tunnel. The pipe joint prefabricated platform 1 adopts a steel box structure, with steel trusses inside and steel plates on the top. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com