Parallel electrode combination, power module and power module set

A technology of power modules and parallel electrodes, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of large stray inductance, increased loss, and limited application, and achieve the effect of reducing stray inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

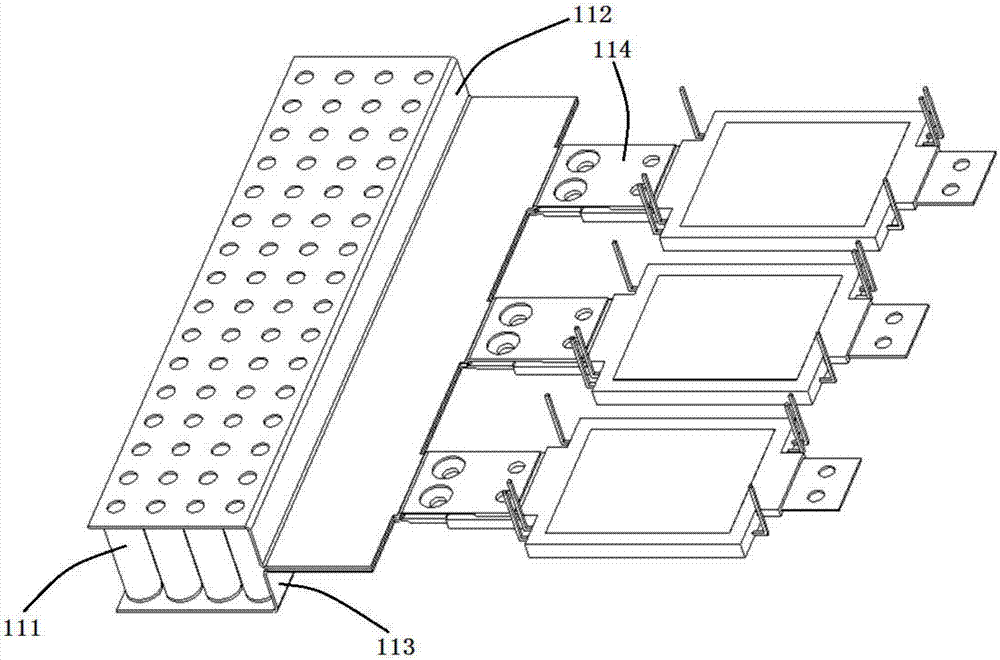

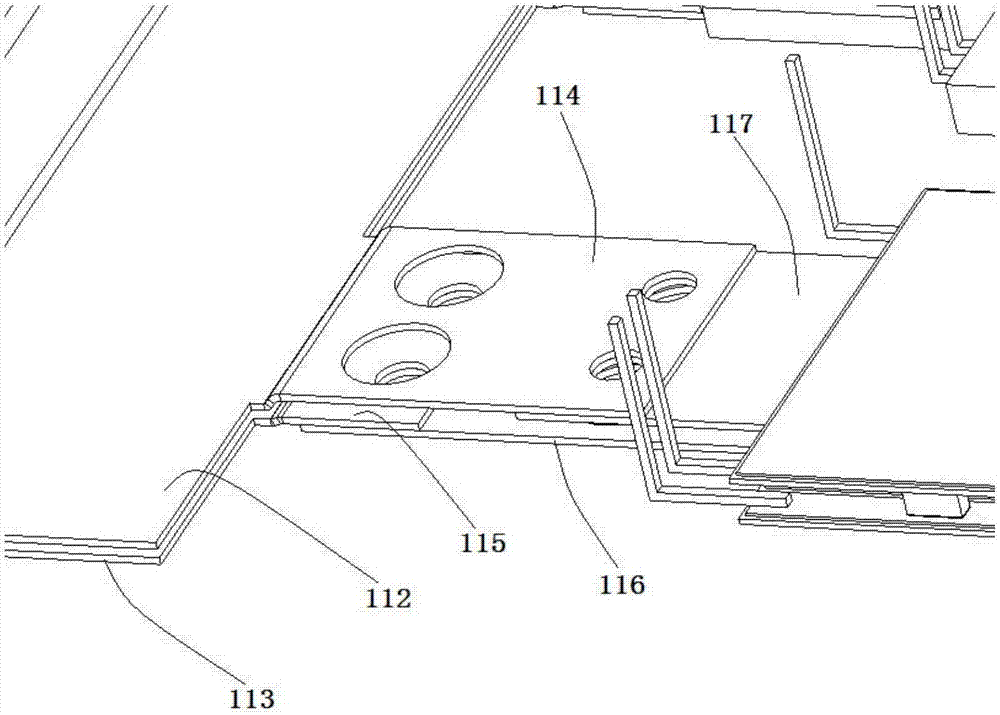

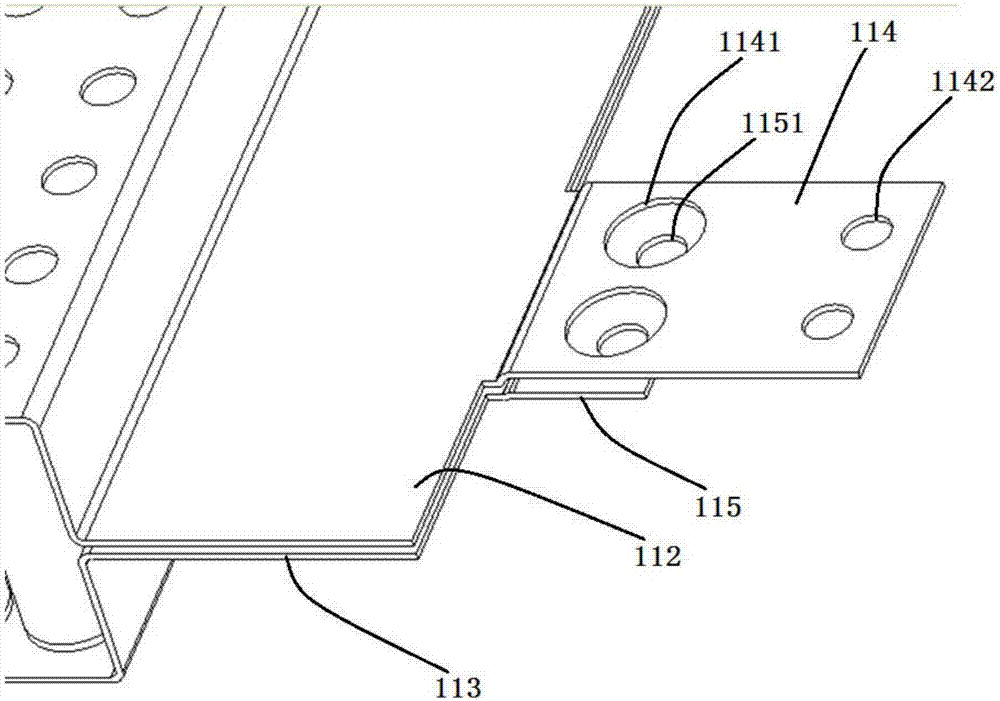

[0057] Embodiment 1 discloses a power module with a combination of electrodes installed in parallel, such as Figure 1-5 As shown, it includes a capacitor with a capacitor electrode combination and a power module with a power module electrode combination. The capacitor electrode combination includes a first capacitor electrode and a second capacitor electrode, the welding part 112 of the first capacitor electrode is connected to the negative pole of the capacitor core group 111, the welding part 113 of the second capacitor electrode is connected to the positive pole of the capacitor core group 111, and the first capacitor electrode The welding part 112 and the second capacitor electrode welding part 113 are plate-shaped and are located in the middle of the capacitor side. The welding part 112 of the first capacitor electrode leads to the connecting part 114 of the first capacitor electrode, and the welding part 113 of the second capacitor electrode leads to the second capacitor...

Embodiment 2

[0069] Embodiment 2 discloses a power module with a combination of parallel parallel electrodes, such as Figure 9 As shown, it includes a capacitor with a capacitor electrode combination and a power module with a power module electrode combination. The capacitor electrode combination includes a first capacitor electrode 212 and a second capacitor electrode 213 facing in parallel. The first capacitor electrode 212 and the second capacitor electrode 213 are both plate-shaped and located in the middle of the side of the capacitor. The electrodes 213 are respectively connected to the positive and negative poles of the capacitor core group 211, such as Figure 10 As shown, the first capacitor electrode 212 is partially raised, and the second capacitor electrode 213 is also partially raised, and the protrusion of the first capacitor electrode 212 and the protrusion of the second capacitor electrode 213 jointly form an accommodation cavity. The power module electrode assembly inclu...

Embodiment 3

[0080] Embodiment 3 discloses a power module with a parallel coaxial electrode combination, such as Figure 13 As shown, it includes a capacitor with a capacitor electrode combination and a power module with a power module electrode combination. The capacitive electrode combination includes a first capacitive electrode and a second capacitive electrode. The welding portion 312 of the first capacitor electrode and the welding portion 313 of the second capacitor electrode are respectively connected to the positive and negative poles of the capacitor core group 311, the welding portion 312 of the first capacitor electrode leads to the connecting portion 314 of the first capacitor electrode, and the second capacitor electrode The connecting portion 315 of the second capacitor electrode is led out from the welding portion 313 of the electrode. The first capacitor electrode welding portion 312 and the second capacitor electrode welding portion 313 are both plate-shaped and located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com