Capacitor with high heat radiation power

A capacitor and high heat dissipation technology, applied in the field of capacitors, can solve the problems of inability to miniaturize equipment, high failure rate, large stray inductance, etc., and achieve the effect of convenient miniaturization design, reduction of installation size, and improvement of heat dissipation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

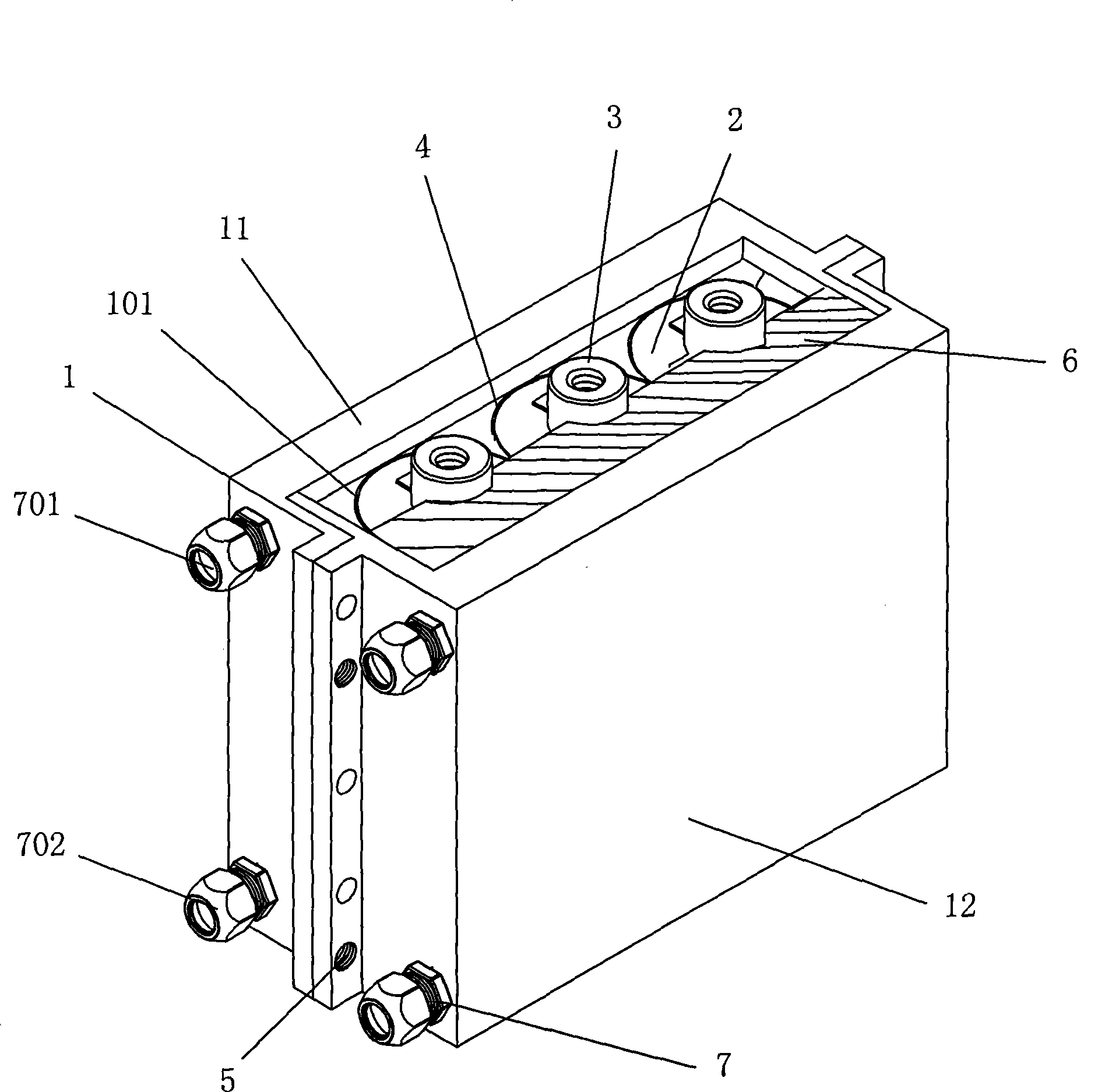

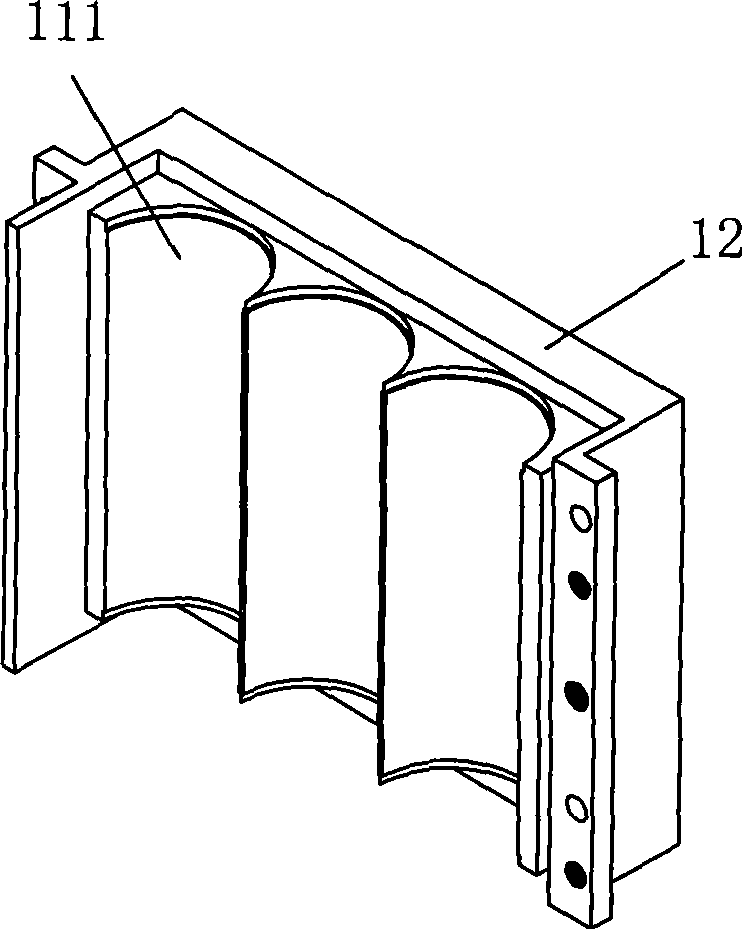

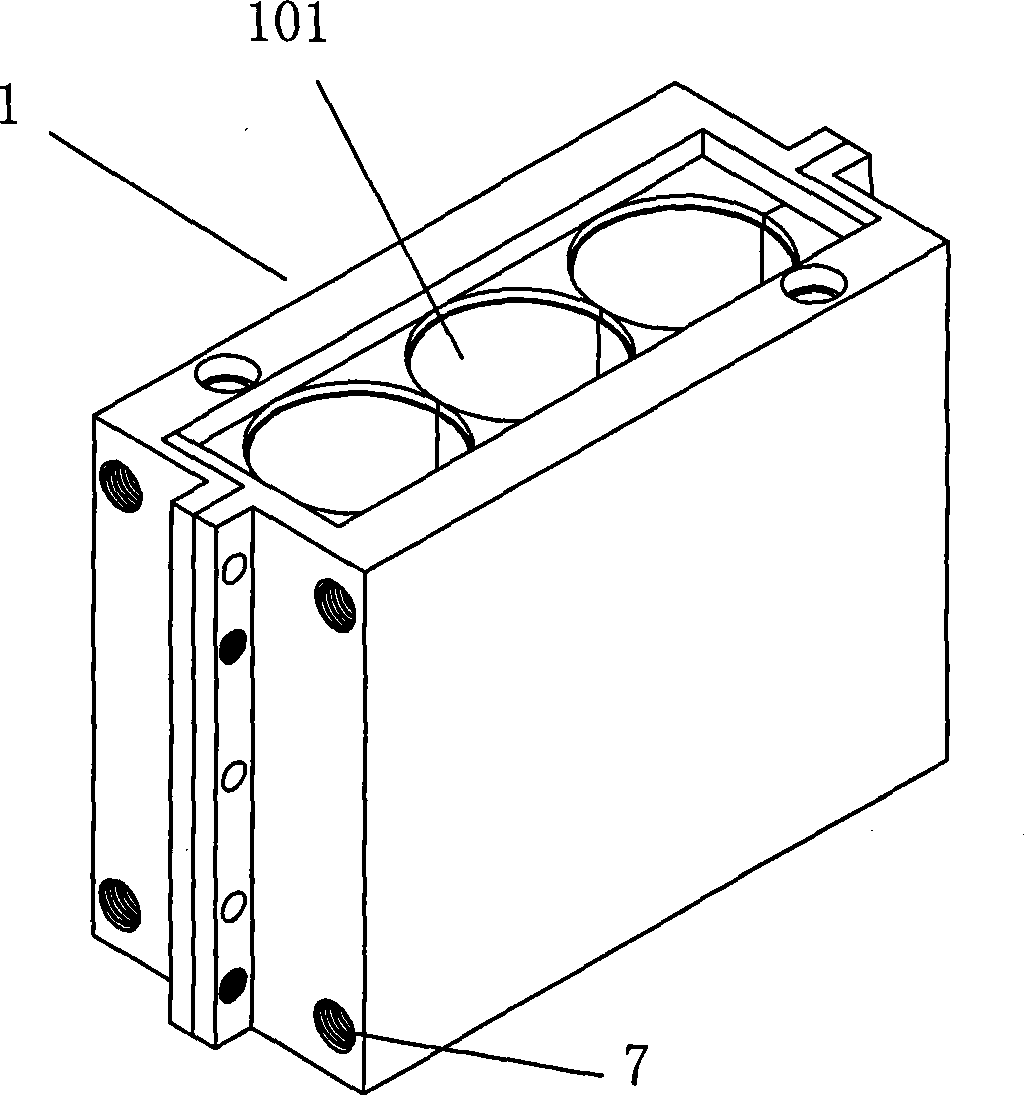

[0029] like Figure 1 to Figure 3 As shown, a capacitor with high heat dissipation power includes a casing 1 and a capacitor core 2 thereof. The casing 1 is composed of two metal shells 11 and 12 with low magnetic permeability. Each metal shell 11 and 12 Both are provided with recesses 111, so that the metal casings 11 and 12 are combined to form the accommodating cavity 101 of the casing 1. The capacitor core 2 is provided with a lead-out end 3, and the capacitor core 2 is covered with an insulating cloth 4 and fitted. In the accommodating cavity 101 , its leading end 3 extends out of the casing 1 , and a fixing member 5 is provided between the combined casings 11 and 12 to connect together. The fixing member 5 can be a screw or a fixing pin. Inside the accommodating cavity 101 The periphery of the capacitor core 2 is also filled with thermally conductive flame retardant resin 6, and each metal shell 11, 12 in the housing 1 is provided with a cooling water channel 7, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com