Integrated semiconductor power assembly and pressing gauge thereof

A semiconductor and high-power technology, applied in the field of integrated semiconductor high-power components and their press-fit fixtures, can solve the problems of increasing circuit stray inductance, affecting the function of power devices, increasing the difficulty of press-fitting, etc., and achieving a compact structure , Easy maintenance, strong heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

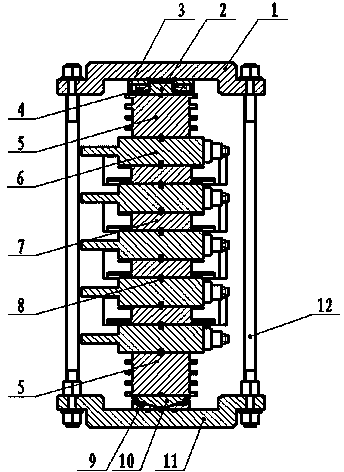

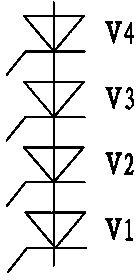

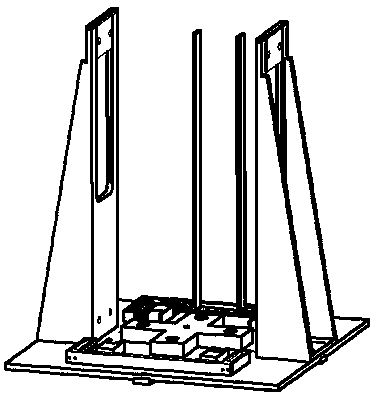

[0022] refer to figure 1 , figure 2 As shown, the present invention discloses an integrated semiconductor high-power assembly, including a bottom plate 11, a top plate 1, and four double-ended screws 12 connecting the bottom plate 11 and the top plate 1, and the top of the bottom plate 11 is sequentially provided with a first buckle. 9 and the second lower fastener 10, the bottom of the top plate 1 is provided with the first upper fastener 2 and the second upper fastener 3 in turn, and the first upper fastener 2 and the second lower fastener 10 are equipped with insulators 5 A plurality of water-cooled radiators 6 are installed between the two insulators 5, and a power device 7 is sandwiched between two adjacent water-cooled radiators 6, and the power device 7 is an integrated gate commutation Thyristor (IGCT), two adjacent 7 are connected in series, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com