Laminated bus bar type electromechanical servo driver

A technology of servo drive and laminated busbar, which is applied in the field of servo drive, can solve the problems that the three-phase full-bridge circuit does not have an absorption circuit, the effect is not as good as the absorption capacitor, and the volume and weight of the shell are increased, so as to reduce the volume of the drive , perfect connection mode, safe and reliable and compact layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

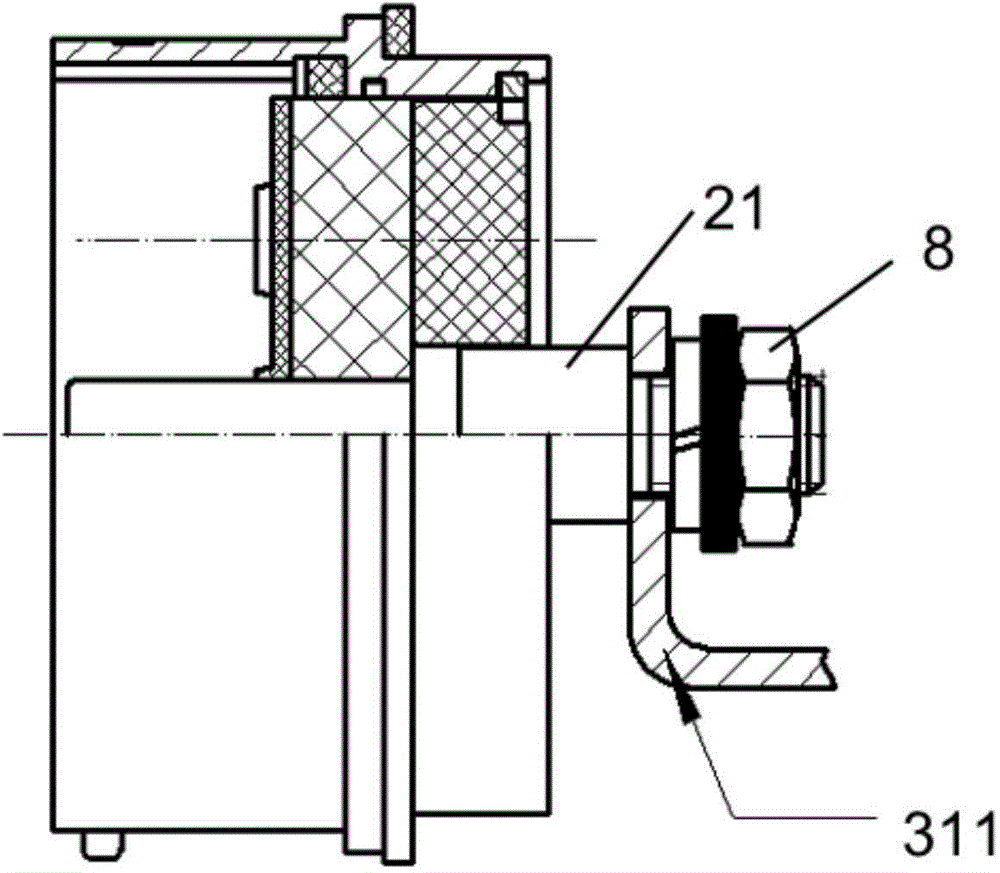

[0032] See figure 1 , Figure 4 with Figure 5 , The present invention is a servo drive, including:

[0033] A power device 1 having a bus terminal 11 and a three-phase terminal 12;

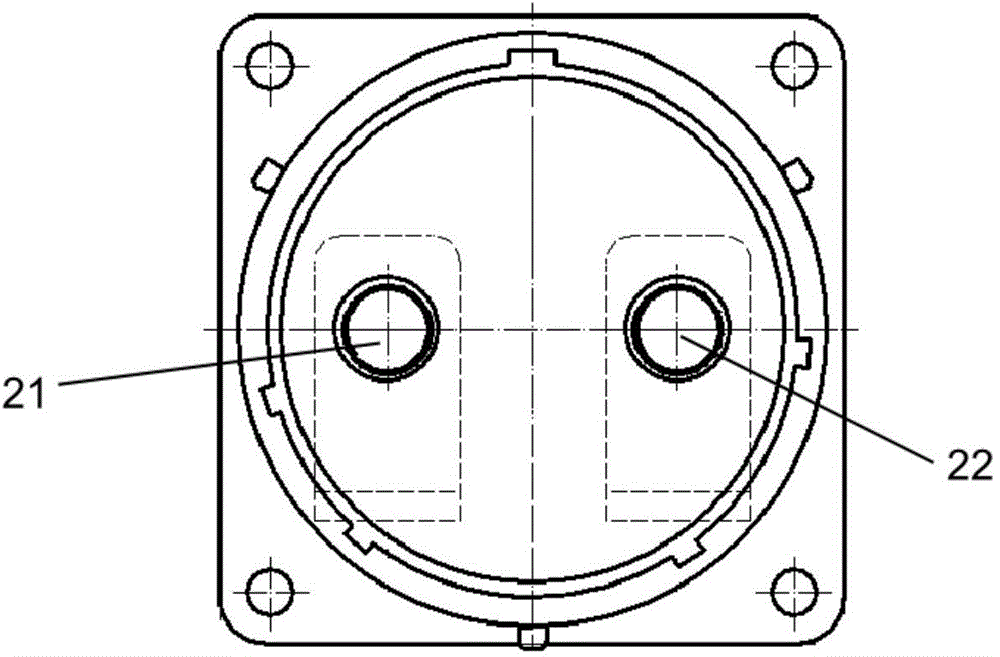

[0034] A socket 2, which is fixedly arranged on the outside of the servo drive;

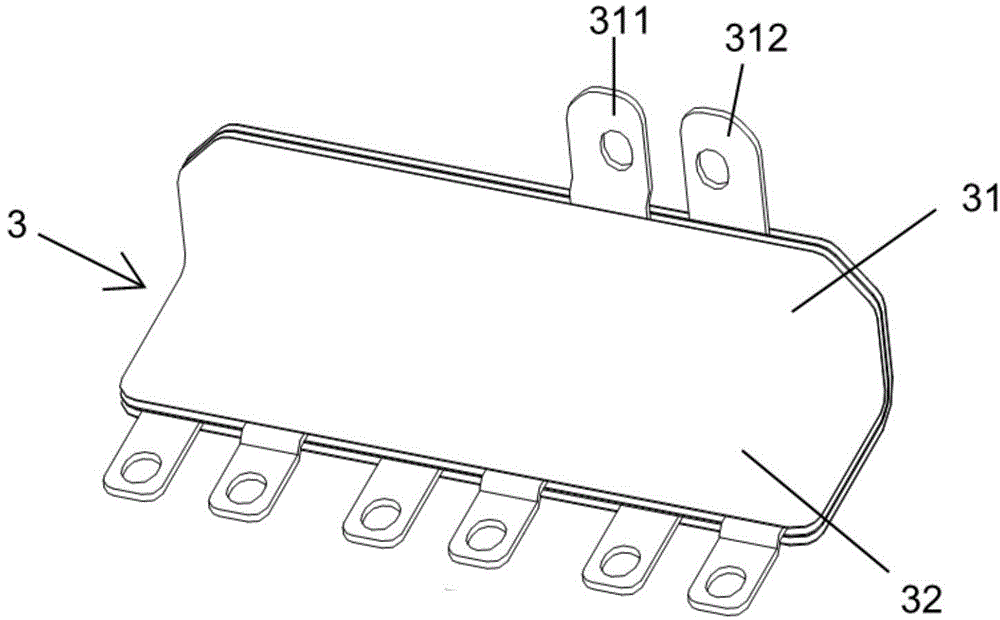

[0035] A laminated busbar 3 is used to connect the power device 1 and the socket 2. The laminated busbar 3 has a strip-shaped structure with a cross-section of an "L" shape, and two "L"-shaped The sides respectively correspond to the first connecting piece 31 and the second connecting piece 32 of the laminated busbar. The first connecting piece 31 is connected to the socket 2, and the second connecting piece 32 is connected to the power device 1 The bus terminal 11 is connected;

[0036] A absorbing capacitor 4 for absorbing the peak voltage generated when the power device is turned off, the absorbing capacitor 4 includes a capacitor terminal, the capacitor terminal is connected to the bus terminal 11 of the power device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com