Ethoxylation reactor

An ethoxylation and reactor technology, applied in the field of ethoxylation reactors, can solve the problems of increased circulation pump load, large safety risks, and easy sudden stop, so as to avoid increased viscosity and expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

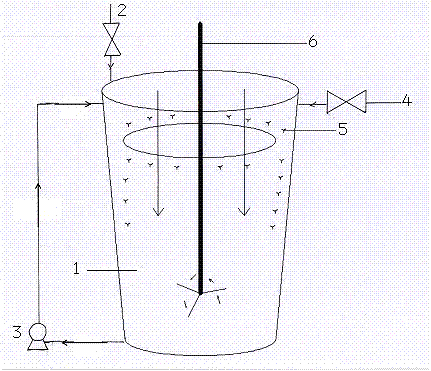

[0012] like figure 1 As shown, the ethoxylation reactor mainly includes: reactor body 1, ethylene glycol inlet 2, circulation pump 3, ethylene oxide inlet 4, spray nozzle 5, frequency conversion agitator 6; The spray nozzle 5 is arranged on the upper part of the inner wall of the reactor body 1, and the ethylene glycol injection port 2 is connected with the spray nozzle 5, and the ethylene glycol enters the reaction in the form of small droplets after being atomized in the spray nozzle. One end of the circulation pump 3 is connected to the bottom of the reactor body 1, and the other end is connected to the spray nozzle 5. After the reaction starts, the circulation pump is turned on, and the reactants at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com