Laser welding system based on machine vision positioning and used for battery box packaging and operating method of laser welding system

A machine vision and laser welding technology, applied in the field of production and manufacturing, can solve problems affecting battery sealing and insulation performance, high product defect rate, wrong welding, etc., to achieve the effect of reducing defective products, increasing the rate of good products, and reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

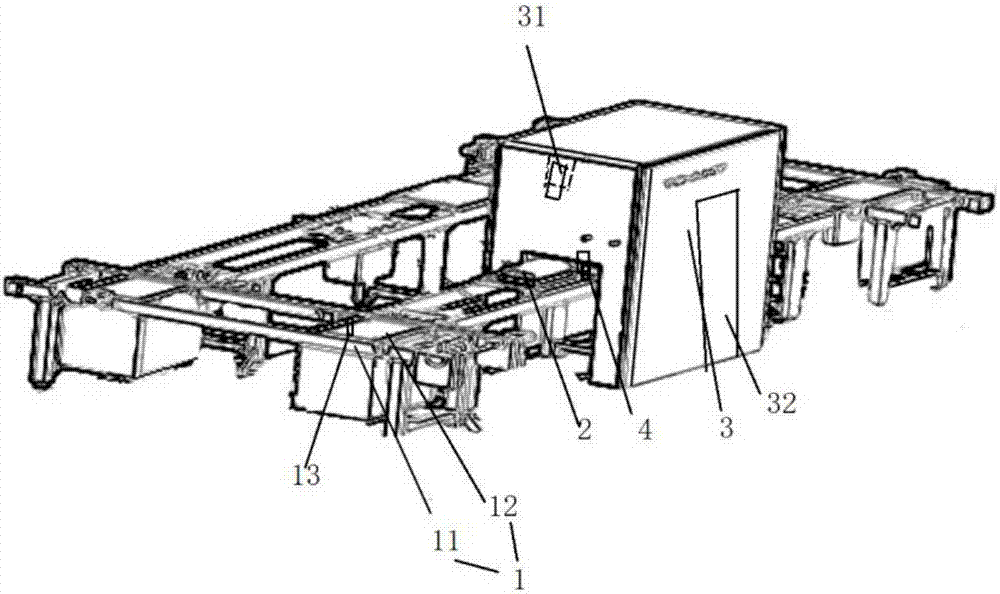

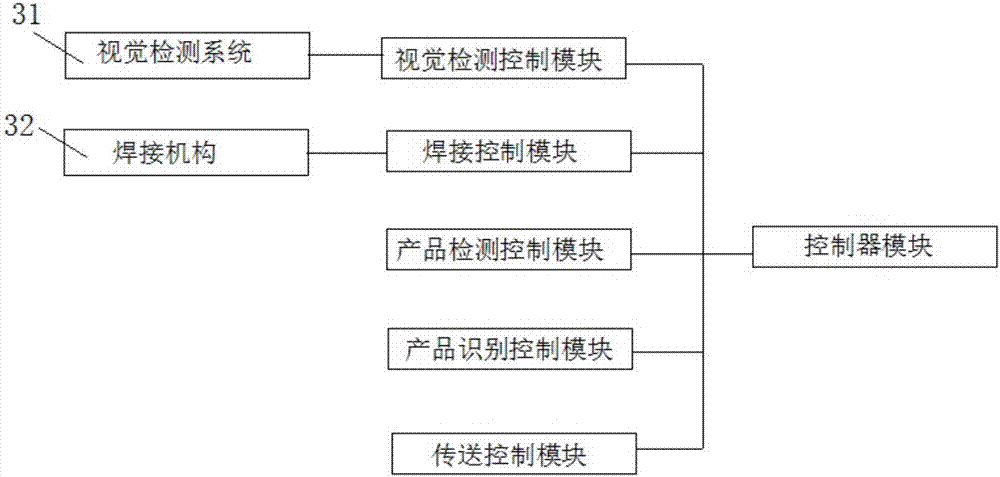

[0031] The battery box packaging laser welding system based on machine vision positioning as shown in the figure includes: a transport mechanism 1, a fixture 2, a welding workstation 3 and a control device, wherein the welding workstation 3 is provided with a visual inspection system 31 and a welding mechanism 32. Both the fixture 2 and the welding workstation 3 are set on the transportation mechanism 1, the welding mechanism 32 is set behind the visual inspection system 31, and the transportation mechanism 1 and the visual inspection system 31 are both connected to the control device.

[0032] In this embodiment, the entrance of the welding workstation 3 is provided with a product detection device 4 for detecting whether a workpiece enters the welding workstation 3, and the product detection device 4 is connected to the control device.

[0033] In this embodiment, the transportation mechanism 1 is ring-shaped, and a support frame 11 is provided therein, and at least one set of...

Embodiment 2

[0039] The battery box packaging laser welding system based on machine vision positioning as shown in the figure includes: a transport mechanism 1, a fixture 2, a welding workstation 3 and a control device, wherein the welding workstation 3 is provided with a visual inspection system 31 and a welding mechanism 32. Both the fixture 2 and the welding workstation 3 are set on the transportation mechanism 1, the welding mechanism 32 is set behind the visual inspection system 31, and the transportation mechanism 1 and the visual inspection system 31 are both connected to the control device.

[0040] In this embodiment, the entrance of the welding workstation 3 is provided with a product detection device 4 for detecting whether a workpiece enters the welding workstation 3, and the product detection device 4 is connected to the control device.

[0041] In this embodiment, the transportation mechanism 1 is ring-shaped, and a support frame 11 is provided therein, and at least one set of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com