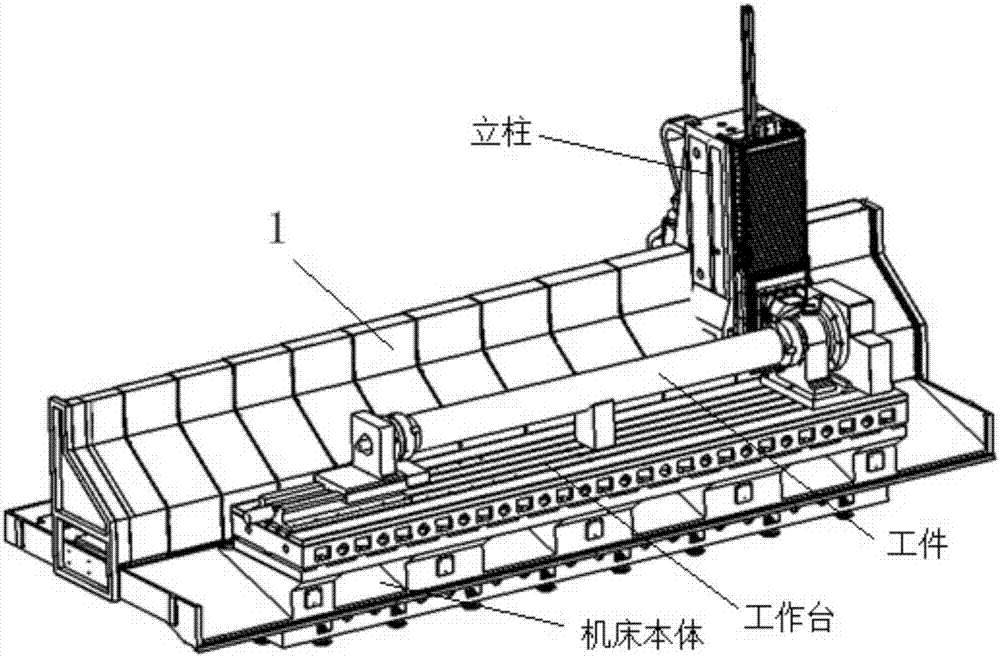

Horizontal stretchable type protection cover of large machining center machine tool

A machining center and horizontal telescopic technology, applied in the field of protective covers, can solve the problems of inconvenient chip removal and chip collection, large space occupation, etc., and achieve the effects of automatic collection, easy operation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

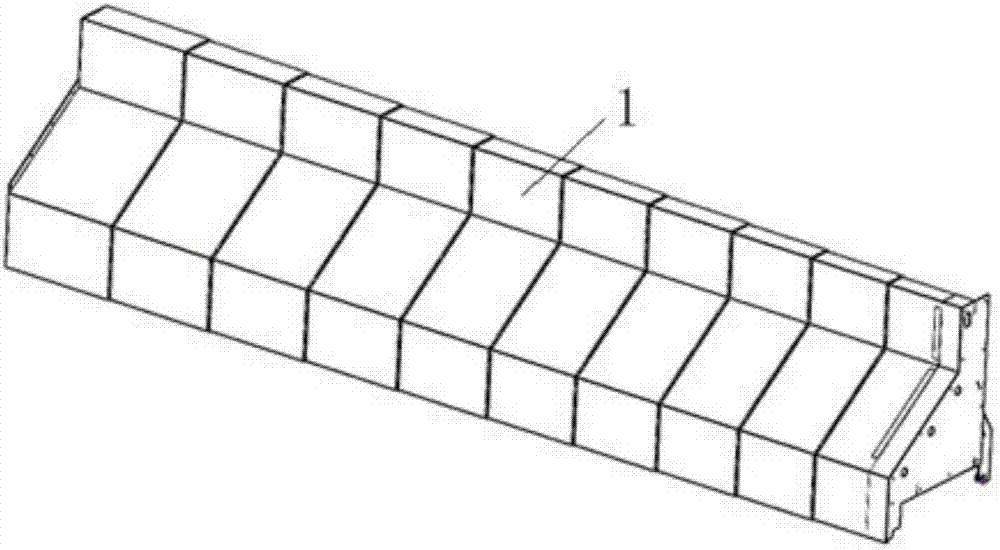

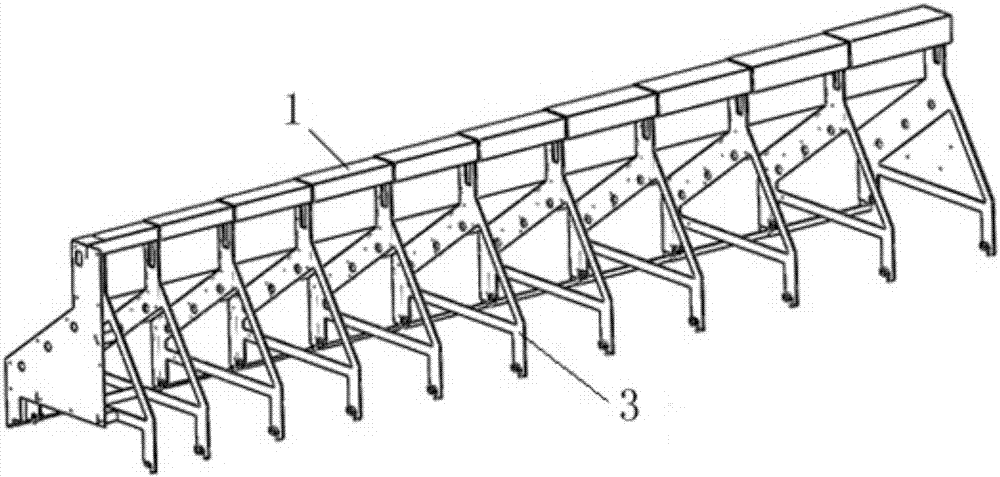

[0022] Such as figure 1 with Figure 5 As shown, a horizontal telescopic protective cover for a large-scale machining center machine tool includes a plurality of cover bodies 1 that are sleeved together. The cover body 1 is a semi-closed structure and is mainly composed of a cover panel 2, a vertical plate 3 and a transition The connecting plate 4 is formed, the cover panel 2 is fixed on the vertical plate 3 through the transition connecting plate 4, and the cover panel 2 has a Z-shaped structure, and the vertical plate 3 has a convex structure.

[0023] Among them, the vertical plate 3 is mainly composed of a triangular plate 5, a vertical top plate 6 and a leg plate 7. The triangular plate 5 is a hollow structure, the top of the triangular plate 5 is provided with a vertical top plate 6, and the bottom of the triangular plate 5 is provided on both sides There are leg plates7. The cover panel 2 is mainly composed of a vertical plate 8, a sloping plate 9, a horizontal plate 10 an...

Embodiment 2

[0026] The transition connecting plate 4 is arranged close to the inner wall of the cover panel 2, the two ends of the transition connecting plate 3 are provided with insertion notches 12, and the transition connecting plate 3 and the cover panel 2 are connected by inserting and rivets. The other structure is the same as the first embodiment. The cover panel is designed with an L-shaped plate so that the edge of the contact area between the cover panel and the transition connecting plate 3 forms a plug-in boss. The connecting area between the transitional connecting plate 4 and the cover panel is designed with an inserting gap to form an inserting process. After the insertion is completed, the vertical plate and the transition connecting plate are fastened together by rivets to ensure the manufacturing accuracy of each section of the shield. After all connections are completed, electric welding reinforcement is performed at the designated position.

Embodiment 3

[0028] A plurality of supporting roller assemblies 13 are arranged between the cover bodies 1 that are sleeved together. The supporting roller assembly 13 is mainly composed of a fixed block 14, a fixed plate 15, a roller frame 16 and a roller 17, and the fixed block 14 is fixed on the transition plate 4, the fixed plate 15 is fixed on the fixed block 14, the fixed plate 15 is provided with a mounting bayonet 18, the roller frame 16 is provided with a fixed card slot 19, the roller frame 16 is fixed to the fixed plate 15 through the fixed card slot 19 On the mounting bayonet 18, the roller 17 is mounted on the roller frame 16. Others are the same as the first embodiment.

[0029] The supporting roller is clamped on the roller bracket through its own slot, and the roller bracket is connected with the shield vertical plate by screws. Structural size requirements: The cut surface of the roller is 0.4~1.0mm higher than the vertical plate, and the specific height depends on the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com