Bamboo product machining process and bamboo table

A processing technology, bamboo product technology, applied in the direction of manufacturing tools, wood processing utensils, mechanical processing of plant materials, etc., can solve the high requirements of craftsmen's craftsmanship, difficulty in realizing production and manufacturing, and inability to mass-produce to meet the demand for round bamboo products, etc. problem, to achieve the effect of simple process and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

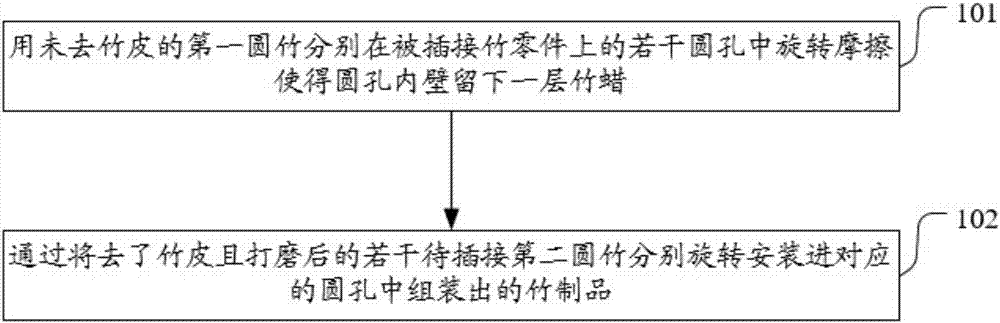

[0037] see figure 1 , the embodiment of the present invention provides a first embodiment of a bamboo product processing technology, comprising:

[0038] 101, rotating and rubbing the first round bamboo without removing the bamboo skin in several round holes on the inserted bamboo parts so that a layer of bamboo wax is left on the inner wall of the round holes;

[0039] 102. A bamboo product assembled by rotating and installing a plurality of second round bamboos to be plugged into corresponding round holes after the bamboo bark has been removed and polished.

no. 2 example

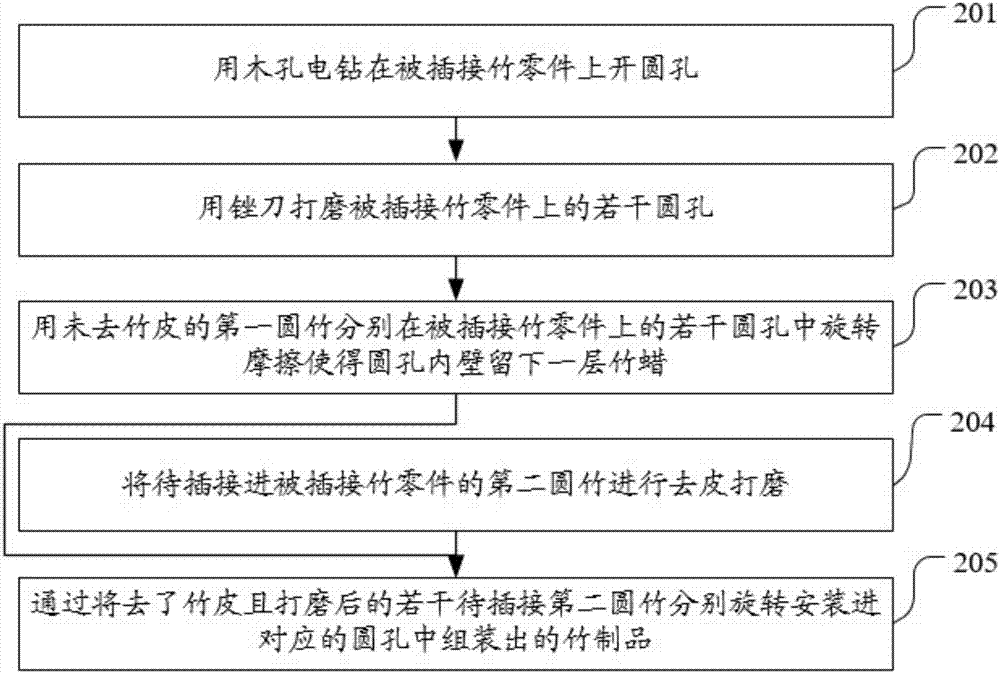

[0040] see figure 2 , the embodiment of the present invention provides a second embodiment of the bamboo product processing technology, comprising:

[0041] 201. Open a round hole on the plugged bamboo parts with a wood hole electric drill.

[0042] 202, grinding some round holes on the inserted bamboo parts with a file.

[0043] 203, rotating and rubbing the first round bamboo without removing the bamboo skin in several round holes on the inserted bamboo parts so that a layer of bamboo wax is left on the inner wall of the round hole;

[0044] 204, peeling and polishing the second round bamboo to be inserted into the inserted bamboo part.

[0045] 205. A bamboo product assembled by rotating and installing a plurality of second round bamboos to be plugged into corresponding round holes after removing the skin of the bamboo and polishing them.

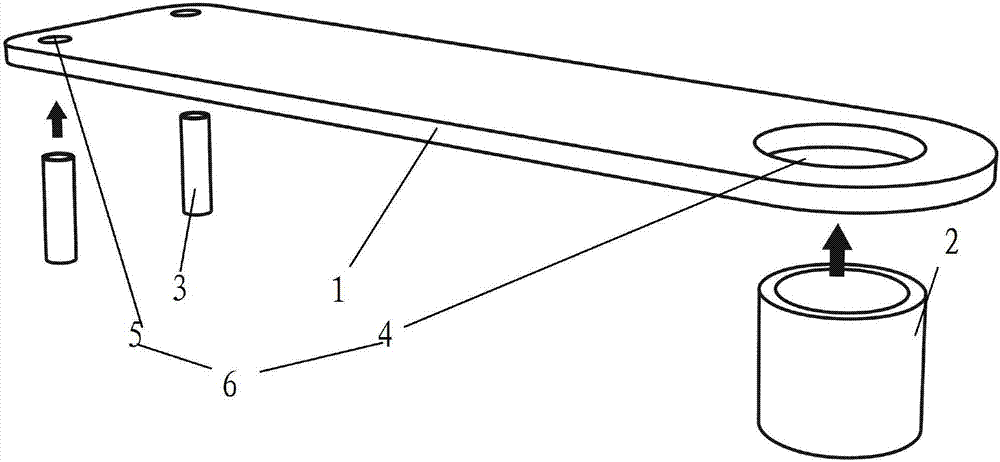

[0046] see image 3 , the embodiment of the present invention provides an embodiment of a bamboo table based on the bamboo product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com