A method of directly transferring molded textures or patterns onto tempered glass

A tempered glass, pattern transfer technology, applied in the direction of copying/marking methods, printing, printing devices, etc., can solve the problems of low product yield, complex chemical formula, high cost, etc., to prevent texture deformation, enhance light and shadow effects, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

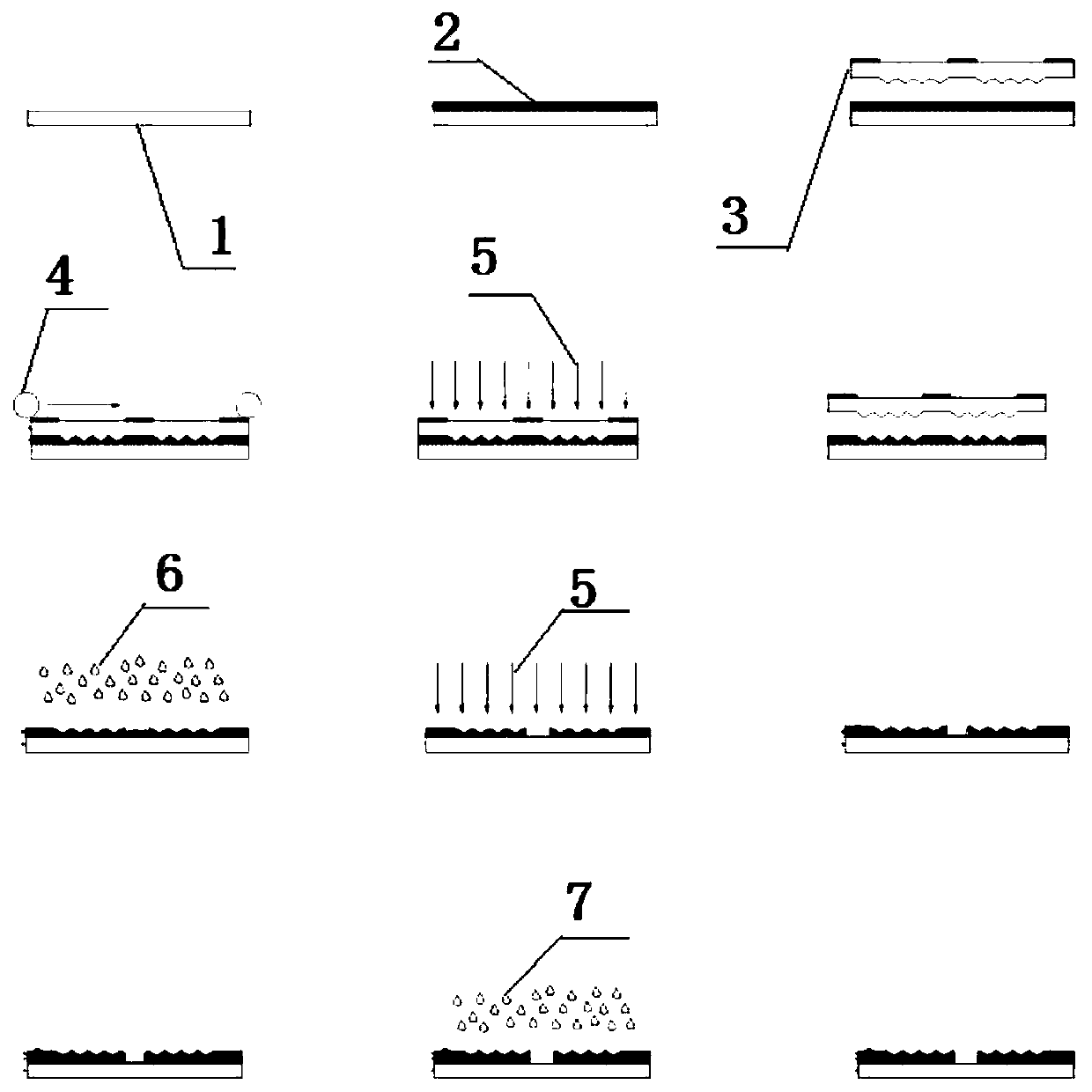

[0036] A method for directly transferring mold texture or pattern onto tempered glass 1, said method comprising the steps of:

[0037] 1) placing the cleaned tempered glass 1 on the arrangement jig;

[0038] 2) Coating a shadowless photosensitive adhesive (hereinafter referred to as UV photosensitive adhesive 2) on the surface of the tempered glass 1;

[0039] 3) Attaching the texture or pattern mold 3 to the surface of the tempered glass 1 that has been coated with UV photosensitive adhesive 2;

[0040] 4) Rolling the tempered glass 1 bonded with the texture or pattern mold 3;

[0041] 5) carry out ultraviolet exposure to the product obtained in step 4) in an ultraviolet light curing machine (not shown);

[0042] 6) separating the texture or pattern mold 3 from the tempered glass 1 to obtain a texture or pattern tempered glass;

[0043] 7) Put the textured or patterned tempered glass 1 obtained in step 6) into an ultrasonic cleaner to clean unexposed glue and overflow glue...

Embodiment 2

[0049] A method for directly transferring mold texture or pattern onto tempered glass 1, said method comprising the steps of:

[0050] 1) placing the cleaned tempered glass 1 on the arrangement jig;

[0051] 2) Shadowless photosensitive glue (hereinafter referred to as UV photosensitive glue 2) has been coated on the surface of the tempered glass 1;

[0052] 3) Attaching the texture or pattern mold 3 to the surface of the tempered glass 1 coated with UV photosensitive adhesive 2;

[0053] 4) Rolling the tempered glass 1 bonded with the texture or pattern mold 3;

[0054] 5) carry out ultraviolet exposure to the product obtained in step 4) in an ultraviolet light curing machine;

[0055] 6) separating the texture or pattern mold 3 from the tempered glass 1 to obtain a texture or pattern tempered glass;

[0056] 7) Put the tempered glass with texture or pattern obtained in step 6) into an ultrasonic cleaning machine to clean unexposed glue and overflow glue;

[0057] 8) Put th...

Embodiment 3

[0067] A method for directly transferring mold texture or pattern onto tempered glass 1, said method comprising the steps of:

[0068] 1) placing the cleaned tempered glass 1 on the arrangement jig;

[0069] 2) Shadowless photosensitive glue (hereinafter referred to as UV photosensitive glue 2) has been coated on the surface of the tempered glass 1;

[0070] 3) Attaching the texture or pattern mold 3 to the surface of the tempered glass 1 coated with UV photosensitive adhesive 2;

[0071] 4) Rolling the tempered glass 1 bonded with the texture or pattern mold 3;

[0072] 5) carry out ultraviolet exposure to the product obtained in step 4) in an ultraviolet light curing machine;

[0073] 6) separating the texture or pattern mold 3 from the tempered glass 1 to obtain a texture or pattern tempered glass;

[0074] 7) Put the tempered glass with texture or pattern obtained in step 6) into an ultrasonic cleaning machine to clean unexposed glue and overflow glue;

[0075] 8) Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com