Utility model efficient purification diatom mud wall material and as preparation method and construction method thereof

A diatom mud, a new type of technology, applied in the field of utility model high-efficiency purification diatom mud wall material and its preparation and construction, can solve the problems of ineffective removal of formaldehyde and TVOC, short storage shelf life, and affect the appearance, etc., to achieve the convenience of large-scale Large-scale production, easy disassembly, and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention aims at the problems in the prior art that the wall material itself releases formaldehyde and other organic substances, the use of strong alkali fillers causes harm to the human body, produces pan-alkaline phenomenon, affects the appearance, and has a short storage shelf life. The present invention provides a utility model with high efficiency purification Diatom mud wall material, preparation method and construction method.

[0036] The materials and reagents used in the following examples can all be obtained from commercial sources.

Embodiment 1

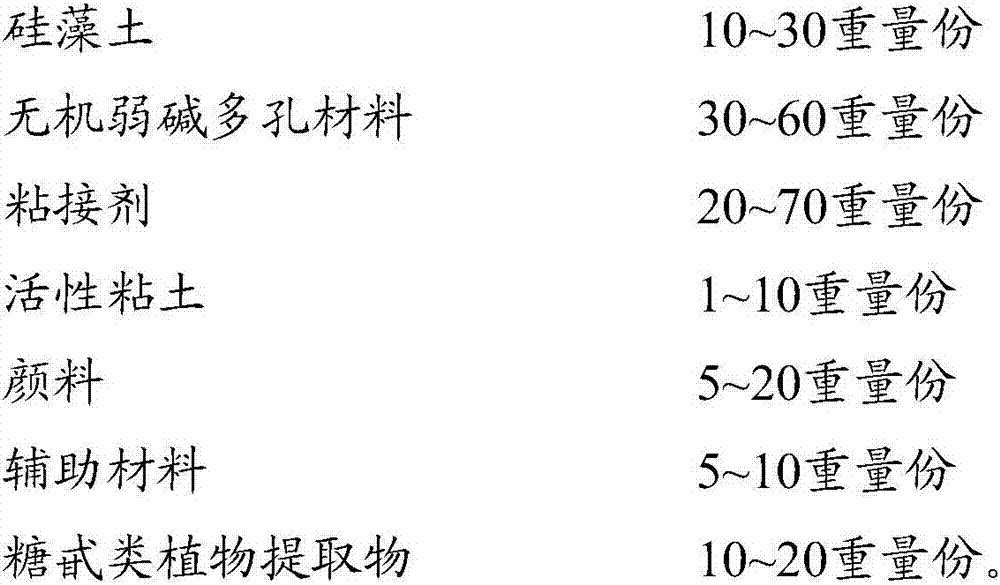

[0038] A utility model high-efficiency purifying diatom mud wall material, which consists of the following components in parts by weight:

[0039]

[0040] The preparation method of above-mentioned utility model high-efficiency purification diatom mud wall material:

[0041] Add the above-mentioned components in proportion to the dry powder mixer and stir at 1500rpm for 40min.

Embodiment 2

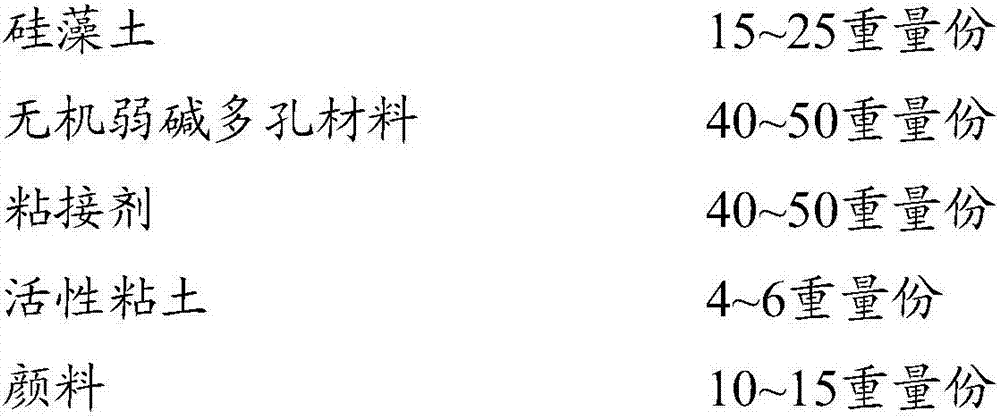

[0043] A utility model high-efficiency purifying diatom mud wall material, which consists of the following components in parts by weight:

[0044]

[0045]

[0046] The preparation method of above-mentioned utility model high-efficiency purification diatom mud wall material:

[0047] Add the above components in proportion to the dry powder mixer and stir at 2000rpm for 20min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com