Method and specially used apparatus for ortho-dichlorobenzene continuous mononitration reaction

A technology of o-dichlorobenzene and a special device, which is applied in the field of continuous mononitration reaction of o-dichlorobenzene, can solve the problems of reactor mass transfer, low heat transfer efficiency, high content of dinitro impurities, and great safety hazards. Achieve the effect of overcoming uneven local concentration, high product yield and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

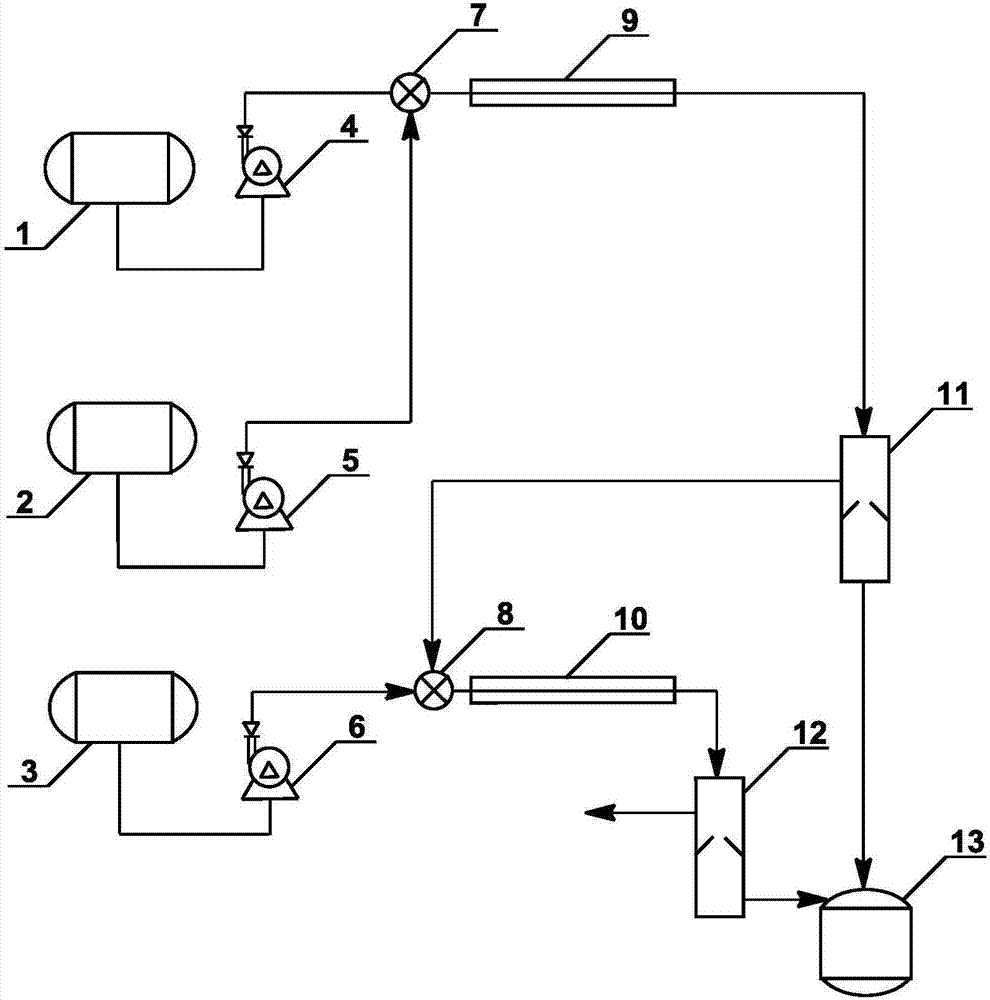

[0030] The first metering pump is used to transport o-dichlorobenzene, and the flow rate is set to 14.7kg / h (100mol / h); the second metering pump is used to transport nitrating agent A, wherein 98% nitric acid 5.5kg / h (85mol / h) ; 98% sulfuric acid 12kg / h (120mol / h); water 2.7kg / h. The third metering pump is used to transport nitrating agent B, wherein 1.3kg / h (20mol / h) of 98% nitric acid. The above-mentioned reaction device is used to carry out the nitration reaction. The first and second tubular reactors have a pipe diameter of 30mm and a pipe length of 20m. The raw material and nitrating agent A are transported synchronously by the pump to the first mixer and then enter the first tubular reactor. The temperature is maintained at 150°C. After staying for 36 minutes, the organic phase enters the second mixer after being separated by the first liquid separator. ; Turn on the third metering pump, and the nitrating agent B is mixed with the organic phase in the second mixer; the...

Embodiment 2

[0032] The first metering pump is used to transport o-dichlorobenzene, and the set flow rate is 147g / h (1mol / h); the second metering pump is used to transport nitrating agent A, wherein 98% nitric acid 55g / h (0.85mol / h); 98% sulfuric acid 120g / h (1.2mol / h); water 27g / h. The third metering pump is used to transport nitrating agent B, wherein, 98% nitric acid 13g / h (0.2mol / h), 98% sulfuric acid 200g / h (2mol / h), water 1760g / h. The above-mentioned reaction device is used to carry out the nitration reaction. The first and second tubular reactors have a pipe diameter of 1mm and a pipe length of 200m. The raw material and nitrating agent A are transported synchronously by the pump to the first mixer respectively, and then enter the first tubular reactor after being mixed. The temperature is maintained at 130°C, and after staying for 40 minutes, the organic phase enters the second mixer after being separated by the first liquid separator. ; Turn on the third metering pump, and the n...

Embodiment 3

[0034]The first metering pump is used to transport o-dichlorobenzene, and the flow rate is set to 147g / h (1mol / h); the second metering pump is used to transport nitrating agent A, wherein 98% nitric acid 55g / h (0.85mol / h); 98% sulfuric acid 120g / h (1.2mol / h); water 270g / h. The third metering pump is used to transport nitrating agent B, wherein 98% nitric acid 130g / h (0.2mol / h), 98% sulfuric acid 50g / h (0.5mol / h), water 4g / h. The above-mentioned reaction device is used to carry out the nitration reaction. The diameter of the first and second tubular reactors is 15 mm, and the length of the tube is 1 m.

[0035] The raw material and nitrating agent A are respectively transported synchronously by the pump to the first mixer for mixing and then enter the first tubular reactor. The temperature is maintained at 100°C, after staying for 45 minutes, the organic phase enters the second mixer after being separated by the first liquid separation device; the third metering pump is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com