A kind of preparation method and preparation device of 3,5-dinitro-o-toluic acid

A technology of dinitro-o-toluic acid and o-toluic acid, which is applied in the preparation of nitro compounds, organic chemistry and other directions, can solve problems such as small axial back-mixing, and achieves reduction of side reactions, convenient operation and production. The effect of high process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

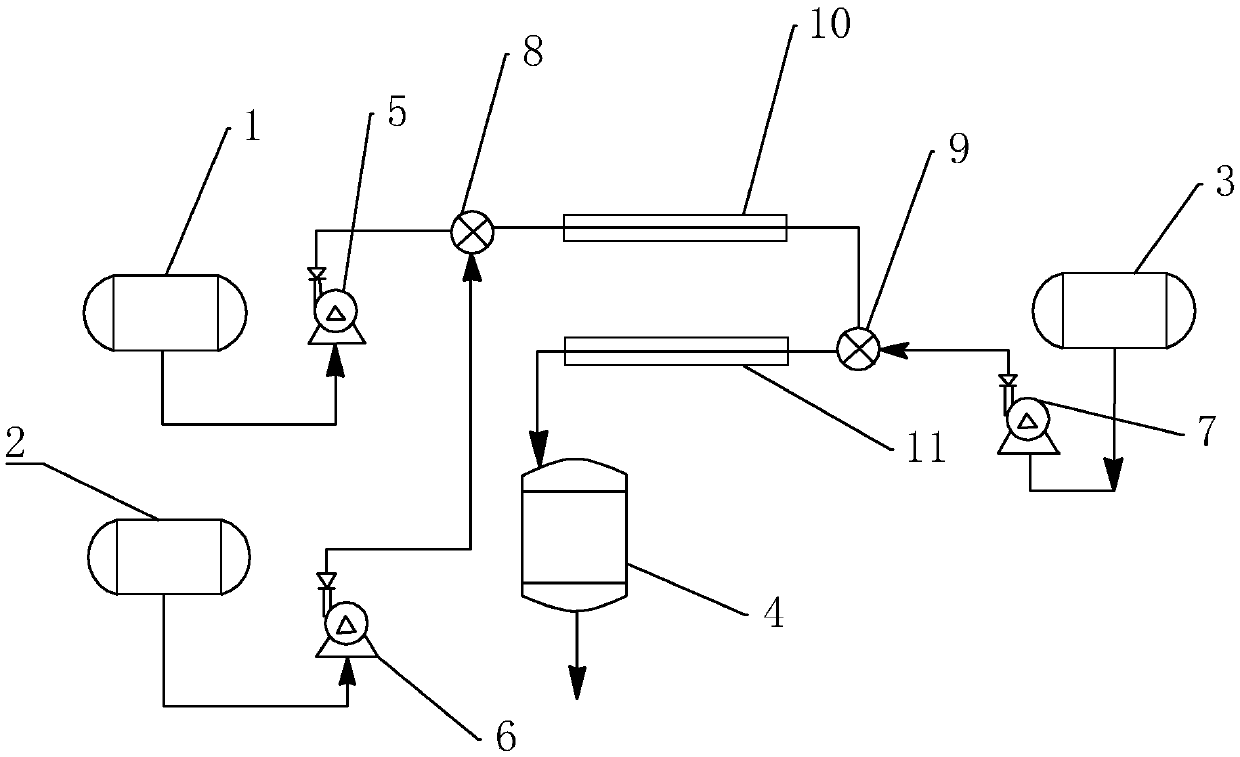

[0037]A preparation device for 3,5-dinitro-o-toluic acid, comprising a first metering tank 1, a second metering tank 2 and a third metering tank 3, the first metering tank 1, the second metering tank 2 and The third metering tank 3 is respectively connected with the first metering pump 5, the second metering pump 6 and the third metering pump 7 through pipelines, and the first metering pump 5 and the second metering pump 6 are connected to the first mixer 8 through pipelines, The first mixer 8 is connected with the first tubular reactor 10 by a pipeline, the third metering tank 3 is connected with a third metering pump 7 by a pipeline, and the third metering pump 7 and the first tubular reactor 10 are connected with a pipeline respectively. The second mixer 9, the second mixer 9 is connected with the second tubular reactor 11 through the pipeline, and the second tubular reactor 11 is connected with the receiving device 4 of the product through the pipeline, wherein the first tu...

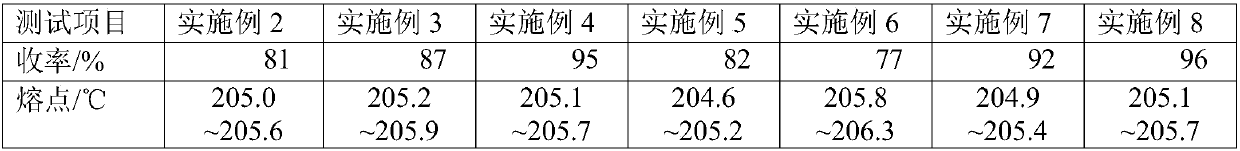

Embodiment 2

[0040] Step 1: Weigh 10.0kg of o-toluic acid in a stirring tank; weigh 20.0kg of 1,2-dichloroethane, pour it into the weighed o-toluic acid and mechanically stir until it is completely dissolved, then transfer to In the first metering tank 1; Take by weighing 9.68 kg of 98% sulfuric acid 14.7kg, 95%-98% nitric acid in the second metering tank 2 and mix;

[0041] Step 2: Feed the materials in the first metering tank 1 and the second metering tank 2 respectively through the corresponding first metering pump 5 and the second metering pump 6 to the first mixer 8 for mixing, and the mixed liquid after uniform mixing enters The first tubular reactor 10 reacts, and the diameter of the first tubular reactor 10 is 1 mm, and the length of the tube is 5 m. The temperature of the first tubular reactor 10 is maintained at 40 ° C by the heat exchange device, and the reaction solution is in the first Reach the second mixer 9 after staying in the tubular reactor 10 for 2min;

[0042] Step 3:...

Embodiment 3

[0045] Step 1: Weigh 10.0kg of o-toluic acid in a stirring tank; weigh 60.0kg of 1,2-dichloroethane, pour it into the weighed o-toluic acid and mechanically stir until it is completely dissolved, then transfer to In the first metering tank 1; Take by weighing 98% sulfuric acid 110.3kg, 95%-98% nitric acid 15.1kg in the second metering tank 2 and mix;

[0046] Step 2: Feed the materials in the first metering tank 1 and the second metering tank 2 respectively through the corresponding first metering pump 5 and the second metering pump 6 to the first mixer 8 for mixing, and the mixed liquid after uniform mixing enters The first tubular reactor 10, the diameter of the first tubular reactor 10 is 30mm, and the length of the tube is 5m. The temperature of the first tubular reactor 10 is maintained at 83°C by the heat exchange device, and the reaction solution is in the first tubular reactor. After staying in the reactor 10 for 4min, it reaches the second mixer 9;

[0047] Step 3: W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com