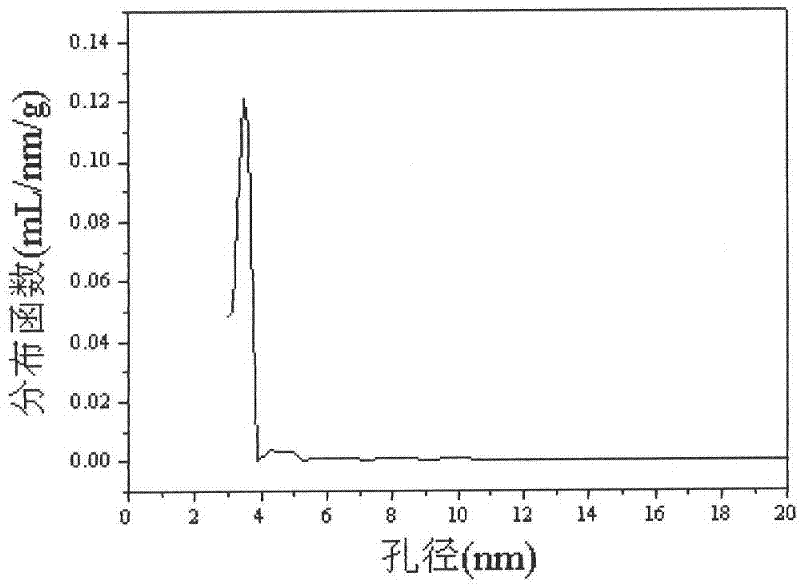

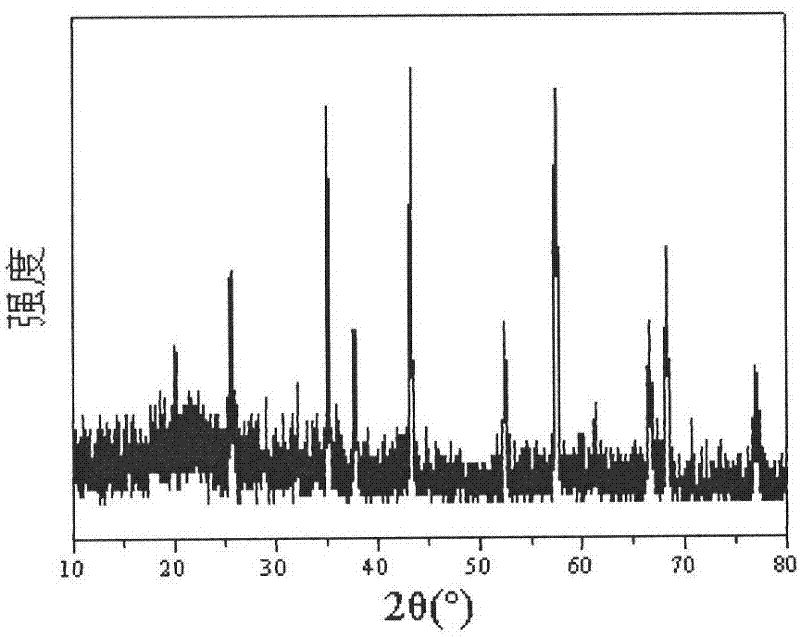

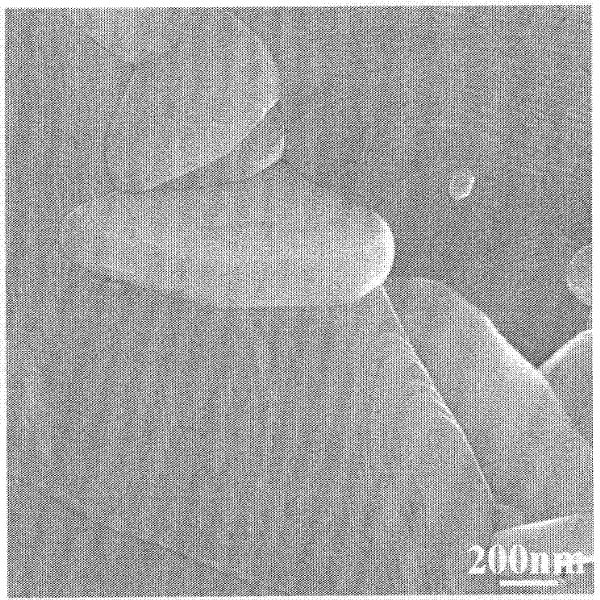

Alpha-Al2O3 nanostructure aggregate material and preparation method thereof

A technology of nanostructures and aggregates, applied in the fields of nanostructure fabrication, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of gel

[0038] ①Mix 67.0g of γ-AlOOH nanoparticles and 730.0mL of deionized water, and disperse evenly with a high-speed mixer to obtain a uniformly dispersed suspension of γ-AlOOH nanoparticles. ②Add 45.0mL of nitric acid solution with a concentration of 1.9mol / L to it To obtain the sol, ③add 40.0mL containing 1.5g La(NO 3 ) 3 ·6H 2 O, 0.94g Y (NO 3 ) 3 ·6H 2 O and 2.2gCo(NO 3 ) 2 ·6H 2 The aqueous solution of O was stirred at a speed of 3000r / min for 30 minutes to obtain a gel.

[0039] (2) Put the above-prepared gel into a 60°C oven for drying under normal pressure, pulverize and sieve.

[0040] (3) Put the xerogel particles prepared in step (2) with a particle size of 40-160 mesh into a muffle furnace, raise the temperature to 550° C. at a rate of 1.7° C. / min, and keep the temperature for 6 hours. The aggregate pre-fired at 550°C was heated to 1420°C at a rate of 70°C / min, and sintered for 2 hours.

[0041] The hardness of the obtained ag...

Embodiment 2

[0043] As described in Example 1, the difference is that step (1) ③ is: add 40.0mL containing 1.1g Nd 2 o 3 , 0.5gY (NO 3 ) 3 ·6H 2 O and 3.3g Co(NO 3 ) 2 ·6H 2 0.5mol / L nitric acid solution of O was stirred at a speed of 3000r / min for 32 minutes to obtain a gel.

[0044] The hardness of the obtained aggregate particles is 19.3GPa, and the density is 3.96g / cm 3 , the α-Al that makes up the aggregate 2 o 3 The thickness of the nanosheet is 10-20nm.

Embodiment 3

[0046] (1) Preparation of gel

[0047] Mix 67.0g of γ-AlOOH nanoparticles with 730.0mL of deionized water, and disperse evenly with a high-speed mixer to obtain a suspension of γ-AlOOH nanoparticles uniformly dispersed. Adding 45.0mL of nitric acid solution with a concentration of 1.9mol / L to obtain a sol, and then adding 40.0mL containing 1.1g Nd 2 o 3 , 2.0g Zr(NO 3 ) 4 ·5H 2 O and 3.6g Mg(NO 3 ) 2 ·6H 2 0.5mol / L nitric acid solution of O was stirred at a speed of 3000r / min for 30 minutes to obtain a gel.

[0048] (2) Put the above-prepared gel into a 90°C oven for drying under normal pressure, pulverize and sieve.

[0049] (3) Put the xerogel particles with a particle size of 40-80 meshes prepared in step (2) into a muffle furnace, heat up to 550° C. for calcination at a rate of 1.7° C. / min, and keep the temperature for 16 hours. The aggregate pre-fired at 550°C was heated to 1400°C at a rate of 70°C / min, and sintered for 2 hours.

[0050] The hardness of the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com