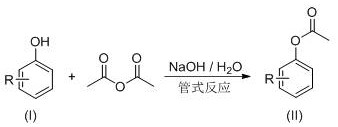

A kind of preparation method of phenyl acetate compound

A technology of phenyl acetate and compounds, which is applied in the field of preparation of phenyl acetate compounds, can solve the problems of expensive acidic catalysts, difficult nitrogen-containing wastewater treatment, large amount of alkaline reagents, etc., and achieves easy automatic control and heat transfer effects Poor, fast heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

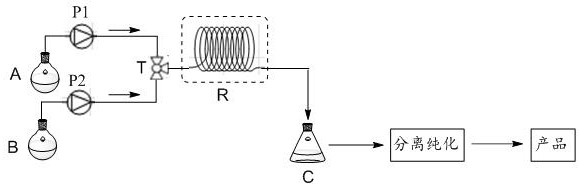

[0022] Add deionized water (30 L), phenol (9.4kg, 100mol) and sodium hydroxide (4.4kg, 110mol) to the first storage tank A in sequence and stir to dissolve until clear, then add deionized water to accurately make up to 50 L to make an aqueous solution with a phenol concentration of 2.0 mol / L, stir evenly and seal it for use. Add 13.3 kg of acetic anhydride (130 mol, density 1.08 g / mL, molar concentration 10.60 mol / L) into the second storage tank B and seal it for use.

[0023] The materials in the first storage tank A and the second storage tank B are transported to the mixer T through the first metering pump P1 and the second metering pump P2 respectively for mixing (the molar flow ratio of phenol: acetic anhydride is controlled to be 1:1.3 ), the mixed solution continuously enters the tubular reactor R for esterification reaction, the temperature inside the tubular reactor R is maintained at 20°C, and the residence time of the mixed solution in the tubular reactor R is 2 min...

Embodiment 2

[0025] In the first storage tank A, add deionized water (30 L), p-cresol (10.8kg, 100mol), sodium hydroxide (4.4kg, 110mol) and stir until clear, then add deionized water Determine the volume to 50 L, make an aqueous solution with a p-cresol concentration of 2.0 mol / L, stir well and seal it for use. Add 13.3 kg of acetic anhydride (130 mol, density 1.08 g / mL, molar concentration 10.60 mol / L) into the second storage tank B and seal it for use.

[0026] Use a metering pump to transport the materials in the first storage tank A and the second storage tank B to the mixer for mixing (control the molar flow ratio of p-cresol: acetic anhydride to be 1:1.3), and the mixed solution enters continuously The esterification reaction was carried out in the tubular reactor, the temperature inside the tubular reactor was maintained at 20° C., and the residence time of the mixed solution in the tubular reactor was 2 minutes. The feed liquid after the esterification reaction flowing out of the...

Embodiment 3

[0028] Add deionized water (30 L), p-nitrophenol (13.9kg, 100mol) and sodium hydroxide (4.4kg, 110mol) to the first storage tank A in sequence and stir until clear, then add deionized water Determine the volume to 50 L, make an aqueous solution with a p-nitrophenol concentration of 2.0 mol / L, stir well and seal it for use. Add 13.3 kg of acetic anhydride (130 mol, density 1.08 g / mL, molar concentration 10.60 mol / L) into the second storage tank B and seal it for use.

[0029] Use a metering pump to transport the materials in the first storage tank A and the second storage tank B to the mixer for mixing (control the molar flow ratio of p-nitrophenol: acetic anhydride to be 1:1.3), and the mixed solution enters continuously The esterification reaction was carried out in the tubular reactor, the temperature inside the tubular reactor was maintained at 20° C., and the residence time of the mixed solution in the tubular reactor was 2 minutes. The feed liquid after the esterificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com