Synthetic method of 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione

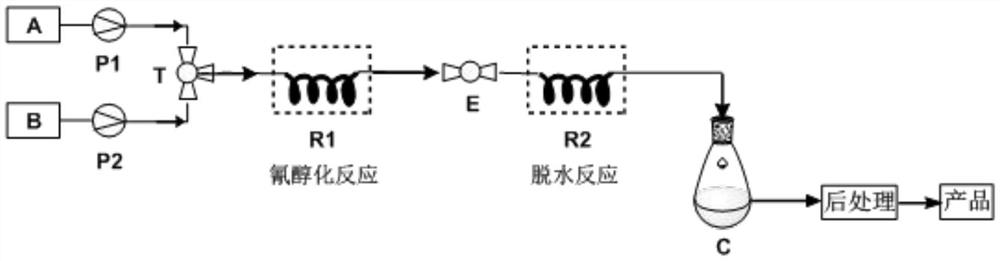

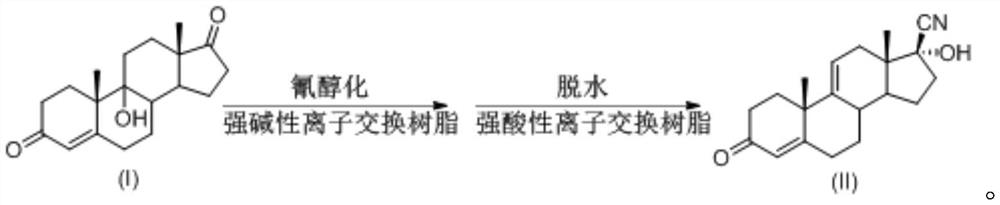

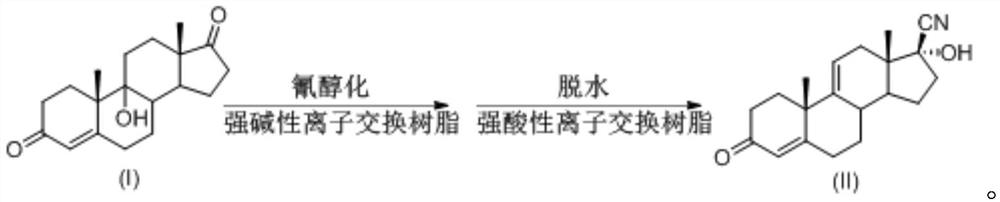

A technology of hydroandrostenedione and synthesis method, which is applied in the synthesis field of 17β-cyano-17α-hydroxy-9-dehydroandrostenedione, can solve the problem of selectivity, poor repeatability, alkaline and acidic reagent dosage It is difficult to deal with problems such as large, cyanide-containing wastewater, etc., to achieve the effects of less online reaction, easy to achieve continuity, and high reuse rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 9-hydroxyandrost-4-ene-3,17-dione (10mmol, 3.02g) in 50mL ethanol and place in the first storage bottle A; dissolve acetone cyanohydrin (12mmol, 1.02g) in 15mL Ethanol is placed in the second storage bottle B, and the materials in the first storage bottle A and the second storage bottle B are transported into the mixer T through the first metering pump P1 and the second metering pump P2 respectively for mixing, and the mixed raw material liquid is continuously Enter the first tubular reactor R1 and carry out cyanation reaction (the inner diameter of the pipeline is 0.31cm, the length of the pipeline is 5m, and the strong basic ion exchange resin is filled in the pipeline 900 (OH), the same in the following examples), both ends are sealed with Floxacin, and the control of 9-hydroxy-androst-4-ene-3,17-dione: the molar flow ratio of acetone cyanohydrin is 1:1.2) , the temperature of the tubular reactor R1 is maintained at 70°C, and the residence time is 25min; af...

Embodiment 2

[0027] 9-Hydroxyandrost-4-ene-3,17-dione (20mmol, 6.04g) was dissolved in 100mL ethylene glycol and placed in the first storage bottle A; acetone cyanohydrin (22mmol, 1.87g) was dissolved Put 25mL of ethylene glycol in the second storage bottle B, the materials in the first storage bottle A and the second storage bottle B are transported through the first metering pump P1 and the second metering pump P2 respectively, and enter the mixer T for mixing , the mixed raw material solution enters the first tubular reactor R1 continuously to carry out the cyanation reaction (the inner diameter of the pipeline is 0.31cm, the length of the pipeline is 2m, the strong basic ion exchange resin is filled in the pipeline, the two ends are sealed with sandstar, and the control 9 The molar flow ratio of -hydroxyandrost-4-ene-3,17-dione: acetone cyanohydrin is 1:1.1), the temperature of the first tubular reactor R1 is maintained at 110° C., and the residence time is 15 minutes. The mixed raw ma...

Embodiment 3

[0029] Dissolve 9-hydroxyandrost-4-ene-3,17-dione (10mmol, 3.02g) in 50mL tetrahydrofuran and place in the first storage bottle A; dissolve acetone cyanohydrin (20mmol, 1.7g) in 20mL tetrahydrofuran and placed in the second storage bottle B. The materials in the first storage bottle A and the second storage bottle B are conveyed through the first metering pump P1 and the second metering pump P2 respectively, and then enter the mixer T for mixing, and the mixed raw material liquid continuously enters the first tubular reactor R1 for Cyanation reaction (the inner diameter of the pipeline is 0.31cm, the length of the pipeline is 3m, the pipeline is filled with strong basic ion exchange resin, both ends are sealed with sandstar, and the control of 9-hydroxyandrost-4-ene-3,17-dione : The molar flow ratio of acetone cyanohydrin is 1:2), the temperature of the first tubular reactor R1 is maintained at 50°C, and the residence time is 1h. The mixed raw material liquid enters the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com