Compressible joist for cast-in-place formwork of abutted seam of fabricated precast slabs and construction method of compressible joist

A construction method and a technology of prefabricated panels, which are applied in the fields of formwork/formwork/working frame, preparation of building components on site, construction, etc., can solve problems such as increasing construction steps, affecting construction efficiency, and wasting wood, so as to improve construction efficiency , save manpower and materials, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

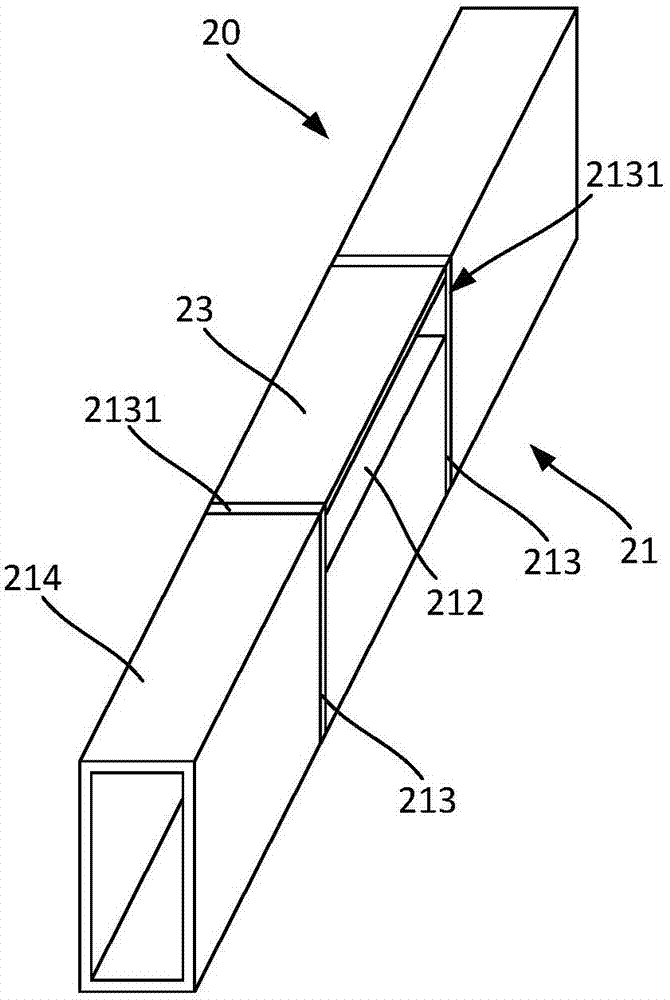

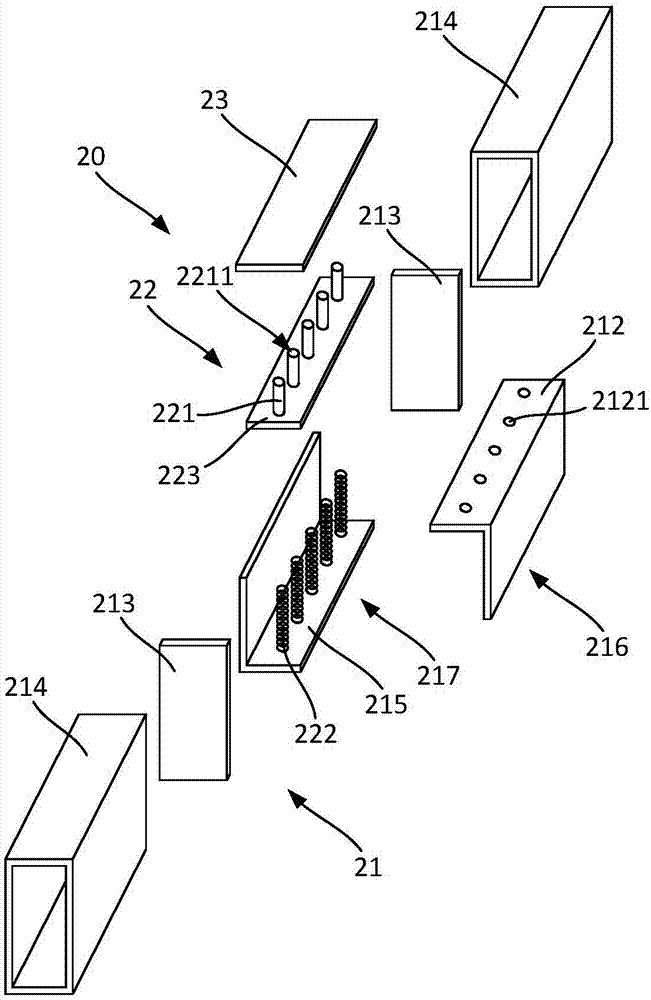

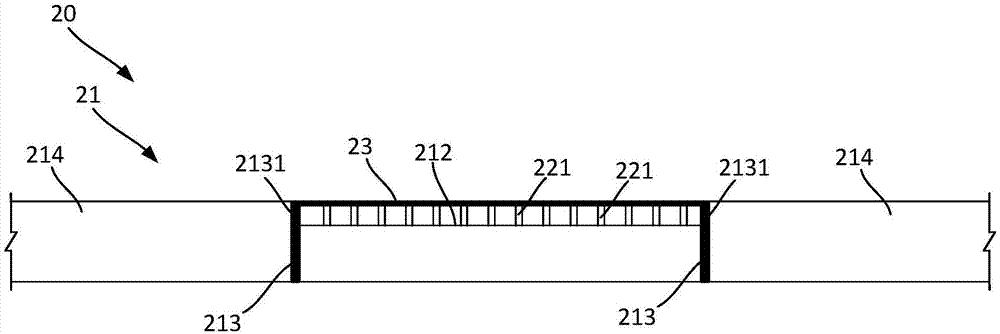

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] refer to figure 1 , the present invention provides a compressible joist for cast-in-place formwork at the seams of assembled prefabricated slabs, which is used to solve the problem that when the assembled prefabricated slab is connected through the cast-in-place section, the cast-in-place section will be disconnected from the bottom of the precast slab There is a height difference, which leads to the inability to support uniformly, which makes the construction consume labor and materials, and also increases the construction steps and affects the construction efficiency. The compressible joist of the present invention is used to support the bottom of the prefabricated slab and the cast-in-place section. For the formwork at the cast-in-place section, the compressible joist can press the formwork into the interior of the joist by adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com